Aug . 15, 2024 06:24 Back to list

Durable OEM Black Binding Wire for Reliable and Secure Document Management Solutions

The Significance of OEM Black Binding Wire in Modern Manufacturing

In the era of industrial evolution and innovation, the manufacturing sector has seen a substantial shift towards optimization, efficiency, and cost-effectiveness. One such product that exemplifies these principles is the OEM (Original Equipment Manufacturer) black binding wire. Often overlooked, this seemingly simple accessory plays a critical role in various applications, from construction and automotive to electronics and packaging.

Understanding OEM Black Binding Wire

OEM black binding wire refers to wire produced by one company (the OEM) to be used in the manufacturing of products by another company. The term binding wire typically denotes a flexible, strong wire employed to bind and support different components together. The black coloring often results from a coating that adds to both the aesthetic and functional properties of the wire, helping to protect against corrosion and environmental elements.

Applications Across Industries

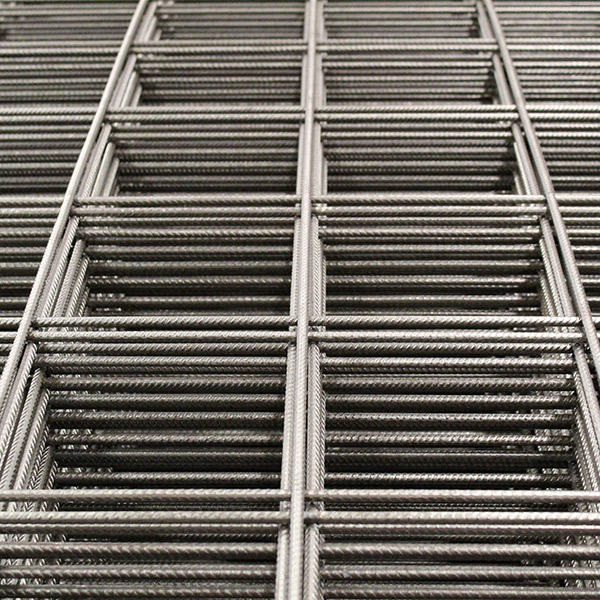

The versatility of OEM black binding wire allows it to find applications in a wide range of industries. In construction, for example, it is used to tie rebar together, ensuring structural integrity in buildings and bridges. The automotive industry employs it to secure various components, improving safety and reliability in vehicles. In electronics, it serves as an effective tool for organizing wires and connections, thereby preventing tangling and damage.

Additionally, in the packaging sector, OEM black binding wire is used for bundling products, enhancing presentation, and providing security. Its strength ensures that bundled items remain secure during transit, while its discreet color often complements the packaging aesthetics.

Quality and Standards

When sourced from reputable manufacturers, OEM black binding wire adheres to stringent quality standards. High-quality wire not only meets the specific requirements of strength and flexibility but also ensures consistency across production batches. This consistency is vital for manufacturers who rely on superior materials to uphold the quality of their final products.

oem black binding wire

Furthermore, OEM suppliers often provide customization options for their binding wire, allowing businesses to choose specific gauges, lengths, and coatings to meet their individual needs. This adaptability makes OEM black binding wire an essential component for businesses aiming for precision in their production processes.

Cost Effectiveness and Supply Chain Efficiency

In addition to its functional benefits, OEM black binding wire offers a cost-effective solution for manufacturers. By reducing waste and improving efficiency, it allows businesses to optimize their supply chains. The bulk procurement of black binding wire further reduces costs, enabling manufacturers to pass these savings on to consumers.

Moreover, the use of OEM suppliers fosters a collaborative relationship that can lead to innovations in design and application. Manufacturers who engage with OEMs for their binding wire needs often leverage the expertise of these suppliers to improve product functionality and performance.

Sustainability Considerations

As industries move towards sustainable practices, the sourcing of materials like OEM black binding wire is increasingly scrutinized. Environmentally conscious manufacturers seek sources that adhere to eco-friendly production processes. Many OEMs are now focused on reducing their carbon footprints and utilizing recycled materials in their wire production, aligning with global sustainability goals.

Conclusion

In summary, OEM black binding wire may appear to be a minor component, yet its impact on various industries cannot be overstated. From enhancing structural integrity in construction to ensuring safety and aesthetics in automotive and electronics applications, its significance permeates multiple levels of production. By understanding its role and advocating for high-quality sourcing practices, manufacturers can harness the full potential of this versatile material, driving innovation and efficiency in a rapidly evolving marketplace.

-

Galvanized 3x3 Sheep Wire Mesh Fence Durable Grassland Fencing Solution

NewsMay.12,2025

-

Pod Slab Reinforcing Mesh Suppliers High-Strength & Durable Solutions

NewsMay.12,2025

-

Galvanized Welded Wire Mesh ISO Factory High-Strength & Corrosion-Resistant

NewsMay.11,2025

-

High-Strength 9 Gauge Welded Wire Mesh Durable & Industrial Grade

NewsMay.11,2025

-

9 Gauge Welded Wire Mesh Heavy-Duty Industrial Strength Solutions

NewsMay.11,2025

-

Durable Galvanized Reinforced Concrete Net Trusted Factories & Suppliers

NewsMay.10,2025