Nov . 04, 2024 01:17 Back to list

building welded mesh manufacturers

The Role of Welded Mesh Manufacturers in Modern Construction

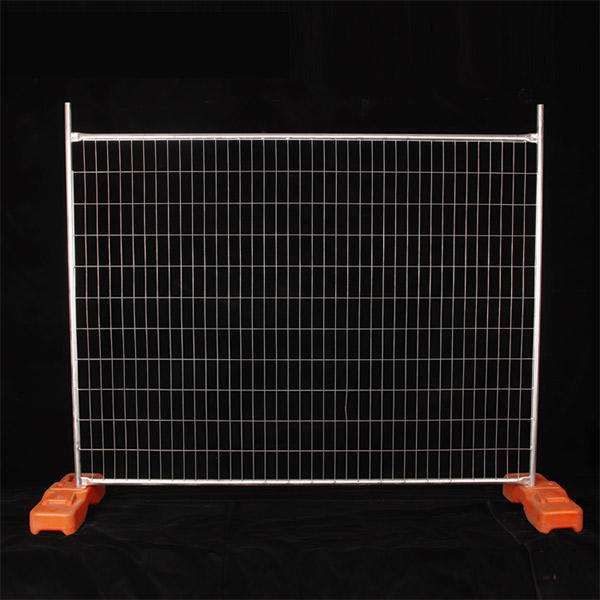

In the realm of modern construction, welded mesh has emerged as a pivotal element, contributing significantly to the efficiency, safety, and durability of structures. Welded mesh, a combination of steel wires that are electrically welded together, is utilized in various applications, including concrete reinforcement, fencing, and industrial flooring. Given its critical role, the significance of welded mesh manufacturers cannot be overstated.

The Importance of Welded Mesh

Welded mesh serves multiple purposes in construction. Its primary function is to provide reinforcement to concrete structures, enhancing their tensile strength and durability. When embedded in concrete slabs, walls, and other structures, welded mesh helps to distribute loads evenly and prevents cracking, thereby prolonging the lifespan of the construction. Additionally, it is used in creating secure enclosures for both commercial and residential properties, providing a robust barrier against unauthorized access.

Quality and Innovation

The quality of welded mesh products is paramount. Manufacturers must adhere to stringent industry standards to ensure that their products meet the requirements of safety and performance. High-quality welded mesh is characterized by tight tolerances, precise welds, and the use of durable materials that can withstand harsh environments. Manufacturers invest in advanced technology and innovative techniques to produce welded mesh that meets these high standards.

Advancements in manufacturing processes have also led to the development of various types of welded mesh, catering to specific applications. From lightweight mesh used in residential construction to heavy-duty options for industrial use, manufacturers play a crucial role in providing tailored solutions that meet the diverse needs of their clients.

building welded mesh manufacturers

Sustainable Practices

As the construction industry increasingly focuses on sustainability, welded mesh manufacturers are also stepping up their efforts to adopt eco-friendly practices. This includes using recycled materials, minimizing waste during the production process, and employing energy-efficient machinery. By prioritizing sustainability, manufacturers contribute to greener construction practices and help builders comply with environmental regulations.

Collaboration with Builders

Welded mesh manufacturers often collaborate closely with construction firms and engineers to develop customized solutions that align with specific project requirements. This partnership not only accelerates the design and construction process but also enhances the overall quality of the project. Manufacturer expertise can provide valuable insights regarding the optimal type of welded mesh for different applications, ensuring that the final product performs effectively.

Conclusion

The importance of welded mesh manufacturers in the construction industry cannot be overlooked. They provide essential products that enhance the strength, durability, and security of structures. By focusing on quality, innovation, and sustainability, these manufacturers are not just serving the needs of their clients but are also contributing to the advancement of the construction industry as a whole. As the demand for robust and reliable construction materials continues to grow, the role of welded mesh manufacturers remains integral to the success of modern building projects. For builders and contractors seeking reliable solutions, partnering with reputable welded mesh manufacturers is a strategic move that can yield significant benefits in terms of project efficiency and overall quality.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025