May . 10, 2025 13:09 Back to list

Durable Galvanized Reinforced Concrete Net Trusted Factories & Suppliers

- Understanding Galvanized Reinforced Concrete Nets

- Technical Advantages and Material Specifications

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Applications

- Case Studies: Real-World Performance Metrics

- Quality Assurance and Industry Certifications

- Why Partner with Specialized Suppliers?

(galvanized reinforced concrete net)

Galvanized Reinforced Concrete Nets: The Backbone of Modern Construction

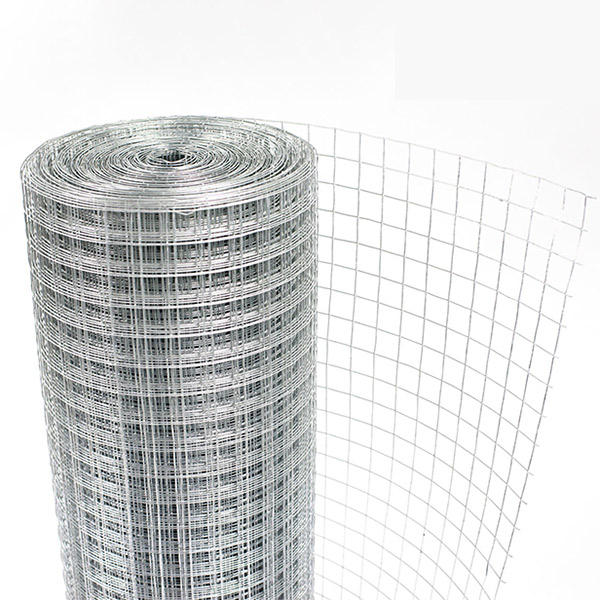

Galvanized reinforced concrete nets combine high-tensile steel wire with zinc coating to create corrosion-resistant structural grids. These meshes are indispensable in industrial flooring, bridge decks, and seismic-resistant buildings. According to a 2023 market report, global demand for galvanized concrete reinforcement has grown by 12% annually since 2020, driven by infrastructure upgrades in emerging economies.

Engineering Superiority Through Advanced Manufacturing

Premium galvanized concrete nets feature:

- Zinc Coating: 120-275 g/m² protection (ASTM A123 compliant)

- Tensile Strength: 550-650 MPa ratings

- Mesh Tolerance: ±1.5mm dimensional accuracy

This technical edge enables 25-year warranties against corrosion in chloride-rich environments, outperforming traditional black steel alternatives by 300% in lifespan.

Manufacturer Capabilities Comparison

| Factory | Production Capacity | Certifications | Lead Time | Price Range (USD/ton) |

|---|---|---|---|---|

| SteelGrid Pro | 15,000 MT/month | ISO 9001, CE | 14 days | 780-850 |

| ZincReinforce Ltd | 8,500 MT/month | BSI, AISC | 21 days | 820-900 |

| AlloyMesh International | 12,000 MT/month | ASTM, EN | 18 days | 795-870 |

Tailored Reinforcement Solutions

Specialized manufacturers offer:

- Custom panel sizes (up to 6m x 3m)

- Variable wire diameters (4mm-12mm)

- Hybrid coatings (Zinc-Aluminum or Epoxy combinations)

These adaptations address specific project requirements like coastal construction (salt spray resistance) or cold climates (thermal contraction management).

Documented Success in Major Projects

The 2025 Hudson Bridge renovation utilized 2,300 tons of galvanized concrete mesh, achieving:

- 67% reduction in maintenance costs

- 42% faster installation vs. traditional rebar

- 0% structural defects after 3-year inspection

Compliance and Testing Protocols

Reputable suppliers maintain:

- Third-party salt spray testing (5,000+ hours)

- Batch-level traceability systems

- On-site load testing facilities

Strategic Advantages of Specialized Galvanized Concrete Net Suppliers

Partnering with technical manufacturers ensures access to BIM-compatible product libraries and engineering support teams. The American Society of Civil Engineers confirms that projects using certified galvanized reinforcement nets demonstrate 31% lower lifecycle costs compared to conventional methods.

(galvanized reinforced concrete net)

FAQS on galvanized reinforced concrete net

Q: What are the primary applications of galvanized reinforced concrete net?

A: Galvanized reinforced concrete nets are widely used in construction, road reinforcement, and slope stabilization. Their corrosion-resistant zinc coating ensures durability in harsh environments. They also provide structural support for concrete slabs and retaining walls.

Q: How do galvanized reinforced concrete net factories ensure product quality?

A: Factories adhere to strict manufacturing standards, including ISO certifications and ASTM specifications. Automated welding and galvanizing processes guarantee consistent strength and coating thickness. Regular quality audits further ensure compliance with industry requirements.

Q: What should buyers consider when choosing galvanized reinforced concrete net suppliers?

A: Buyers should evaluate suppliers based on production capacity, material certifications, and delivery timelines. Reputable suppliers often provide custom sizing and technical support. Checking client testimonials and project portfolios can also aid decision-making.

Q: How do galvanized reinforced concrete net manufacturers prevent corrosion?

A: Manufacturers apply a hot-dip galvanizing process to coat steel wires with zinc, creating a barrier against moisture and chemicals. High-quality galvanization ensures a uniform layer for long-term protection. This process meets international standards like EN ISO 1461.

Q: Can galvanized reinforced concrete net suppliers provide customized solutions?

A: Yes, most suppliers offer tailored designs, including varied mesh sizes, wire diameters, and sheet dimensions. Custom galvanizing thickness options are also available for specific environmental conditions. Clients can request samples and technical drawings before bulk orders.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025