Oct . 30, 2024 18:38 Back to list

cold ribbed steel bar for reinforcing mesh suppliers

Understanding Cold Ribbed Steel Bars for Reinforcing Mesh A Supplier's Perspective

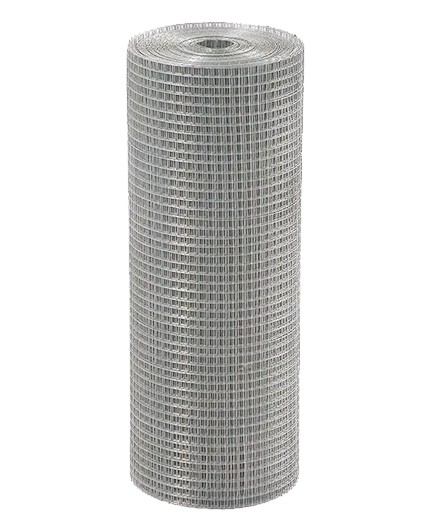

Cold ribbed steel bars have become an essential component in the construction industry, particularly in the production of reinforcing mesh. These bars provide enhanced tensile strength and superior bonding capabilities, which are crucial for ensuring structural integrity in concrete applications. As construction practices continue to evolve, the demand for reliable suppliers of cold ribbed steel bars is on the rise.

Cold ribbed steel bars are produced through a process that involves the cold working of steel, which increases the hardness and tensile strength of the material. This process creates ribbed surfaces on the bars, improving the mechanical interlocking with concrete. Such properties make them ideal for various construction applications, including beams, slabs, and columns, enhancing the overall durability and longevity of the structures.

Suppliers play a critical role in providing high-quality cold ribbed steel bars. The choice of a reliable supplier can significantly impact the construction project's success. When selecting a supplier, it's essential to consider factors such as industry reputation, product quality, and adherence to international standards. Suppliers who comply with ASTM, ISO, or EN standards are often preferred, as these certifications indicate a commitment to quality and reliability.

cold ribbed steel bar for reinforcing mesh suppliers

In addition to product quality, suppliers should offer a range of sizes and specifications to meet diverse project requirements. Different construction projects may require varying dimensions and grades of steel bars, and suppliers who can provide a comprehensive inventory are more likely to satisfy their clients' needs. Additionally, offering customized solutions can further enhance a supplier's appeal in a competitive market.

Another vital aspect to consider is the supplier's ability to maintain consistent supply and timely delivery. Construction schedules can be adversely affected by delays in materials, so working with a supplier who understands the importance of timely delivery can help mitigate potential setbacks. Establishing a good working relationship with suppliers can lead to better terms, pricing, and service, which ultimately adds value to the construction project.

As the construction industry continues to embrace more sustainable practices, suppliers of cold ribbed steel bars are also looking at eco-friendly production methods. Recycling and using lower carbon footprint steel can appeal to environmentally conscious clients and align with global sustainability goals.

In conclusion, cold ribbed steel bars are vital for reinforcing mesh in construction, and selecting the right supplier is crucial for ensuring quality and reliability. With a focus on product quality, a diverse range of options, timely delivery, and sustainable practices, suppliers can play a significant role in the success of construction projects, paving the way for safer and more resilient structures.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025