شوبات . 15, 2025 14:15 Back to list

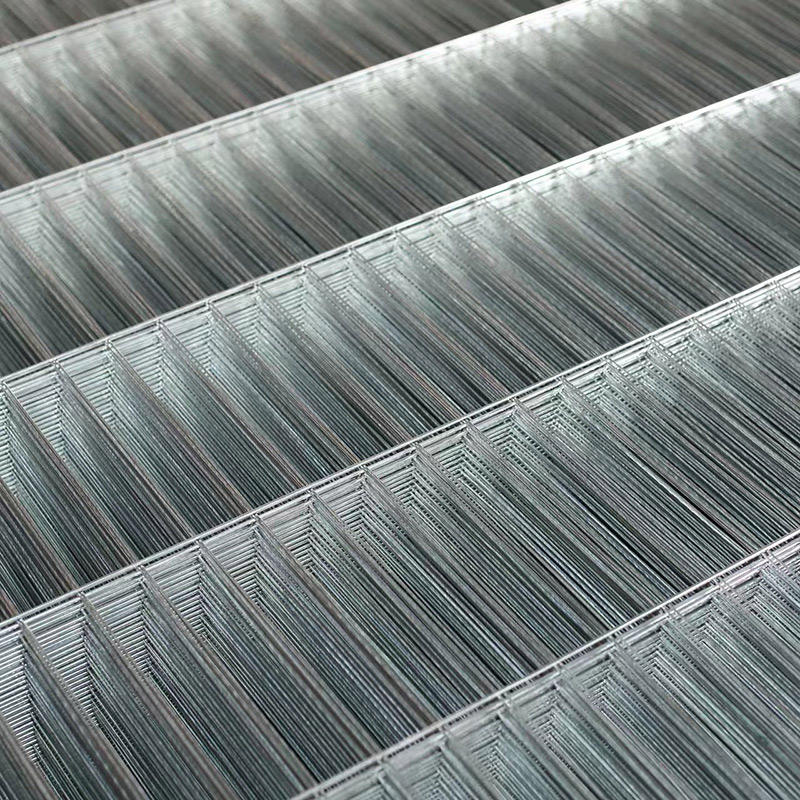

welded wire mesh for industry factories

Black iron wire, often referred to in the industry as ungalvanized iron wire, serves as a crucial material in numerous applications globally. As an OEM (Original Equipment Manufacturer) product, black iron wire garners attention for its versatility, durability, and cost-effectiveness.

Expert insights highlight black iron wire’s strategic importance in industrial applications as well. Its role in machinery and equipment manufacturing cannot be understated. Here, precision and reliability are paramount, and OEM producers are relied upon to deliver wire tailored to stringent industrial standards. Engineers and product developers appreciate its tensile properties which support complex operation mechanisms within various machinery components. Authoritativeness in this domain is underlined by stringent quality inspections that OEMs typically enforce before deployment. Ensuring that the wire meets specific industry standards enhances trustworthiness and establishes long-term relationships within buyer-supplier networks. The repeatability of these standards across different batches speaks to the reliability of black iron wire as an industrial staple. However, investing in black iron wire also requires knowledge of its limitations – notably its rust susceptibility. Therefore, a key expertise area involves advising customers on preventive maintenance. Coating options and regular inspections prolong the life of black iron wire, a consideration that should be communicated during sales and distribution. Ultimately, the trustworthiness of OEM black iron wire relies on consistent product quality assurance and the clarity with which manufacturers communicate its potential benefits and limitations. By fostering transparency and understanding application nuances, OEMs can build reputations for reliability and establish themselves as leaders in the black iron wire market. Understanding the needs and expectations of different market segments allows OEMs to deliver tailored black iron wire solutions. With this approach, black iron wire remains not just a material but a trusted partner in the creation, development, and maintenance of a myriad of infrastructural frameworks and everyday applications. This synergy between universal application flexibility and OEM-specific customization cements black iron wire’s status as an indispensable material across industries worldwide.

Expert insights highlight black iron wire’s strategic importance in industrial applications as well. Its role in machinery and equipment manufacturing cannot be understated. Here, precision and reliability are paramount, and OEM producers are relied upon to deliver wire tailored to stringent industrial standards. Engineers and product developers appreciate its tensile properties which support complex operation mechanisms within various machinery components. Authoritativeness in this domain is underlined by stringent quality inspections that OEMs typically enforce before deployment. Ensuring that the wire meets specific industry standards enhances trustworthiness and establishes long-term relationships within buyer-supplier networks. The repeatability of these standards across different batches speaks to the reliability of black iron wire as an industrial staple. However, investing in black iron wire also requires knowledge of its limitations – notably its rust susceptibility. Therefore, a key expertise area involves advising customers on preventive maintenance. Coating options and regular inspections prolong the life of black iron wire, a consideration that should be communicated during sales and distribution. Ultimately, the trustworthiness of OEM black iron wire relies on consistent product quality assurance and the clarity with which manufacturers communicate its potential benefits and limitations. By fostering transparency and understanding application nuances, OEMs can build reputations for reliability and establish themselves as leaders in the black iron wire market. Understanding the needs and expectations of different market segments allows OEMs to deliver tailored black iron wire solutions. With this approach, black iron wire remains not just a material but a trusted partner in the creation, development, and maintenance of a myriad of infrastructural frameworks and everyday applications. This synergy between universal application flexibility and OEM-specific customization cements black iron wire’s status as an indispensable material across industries worldwide.

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025