تشرینی یەکەم . 12, 2024 11:06 Back to list

Black Annealed Soft Wire Manufacturing Process and Techniques Overview

Black Annealed Soft Wire Factory A Pivotal Player in the Wire Industry

In the competitive world of manufacturing, the black annealed soft wire factory stands out as an essential player providing high-quality wire products for various applications. This facility specializes in the production of black annealed wire—known for its exceptional strength, ductility, and corrosion resistance—making it a preferred choice in several industries. Understanding the processes, benefits, and applications of black annealed soft wire can shed light on why this factory is pivotal in the wire production landscape.

The Production Process

The manufacturing of black annealed soft wire involves several critical steps. Initially, high-quality steel wire rods are drawn through a series of dies to achieve the desired diameter. This drawing process not only shapes the wire but also enhances its tensile strength. Once the wire is drawn, it undergoes an annealing process, where it is heated and then slowly cooled. This thermal treatment is crucial as it relieves internal stresses and increases the wire’s flexibility, making it softer and easier to work with.

The final step is the application of a specific coating, which gives the wire its characteristic black color. The black finish is achieved through oxidation or other methods, providing additional protection against rust and enhancing its aesthetic appeal. The meticulous attention to detail in each phase of production ensures that the finished product meets industry standards.

Key Features of Black Annealed Soft Wire

Black annealed soft wire boasts several key features that contribute to its wide usage. Firstly, its malleability allows for easy bending and twisting, making it ideal for a variety of applications such as fencing, tying, and crafting. The wire's strength ensures that it can withstand considerable loads without breaking or deforming, which is particularly important in construction and agricultural settings.

black annealed soft wire factory

Additionally, the wire’s black finish not only enhances its appearance but also offers improved resistance to environmental factors such as moisture. This quality makes it particularly suitable for outdoor applications, including wire fencing and gardening projects, where exposure to the elements is common.

Applications Across Industries

The versatility of black annealed soft wire renders it useful in numerous industries. In the construction sector, it is commonly used for reinforcing concrete, anchoring, and tying rebar. Its strength and flexibility allow construction workers to secure structures efficiently. In agriculture, farmers often utilize this wire for fencing livestock, trellising plants, and securing tools. Its ease of use and durability make it an invaluable asset in farming operations.

Moreover, the crafting and DIY communities have embraced black annealed wire for various creative projects. Artists and crafters utilize it for making sculptures, jewelry, and decorative items due to its pliability and aesthetic appeal. This further expands the market for black annealed soft wire, creating a unique niche that bridges industrial and artistic applications.

The Future of Black Annealed Soft Wire Manufacturing

As industries evolve and demand for high-quality materials increases, black annealed soft wire factories are poised to adapt and innovate. Investing in advanced manufacturing technologies and sustainable practices will be crucial for these factories. Emphasizing environmental responsibility can enhance their market position while meeting regulatory standards and consumer preferences for eco-friendly products.

In conclusion, the black annealed soft wire factory plays a vital role in producing a versatile and durable product that serves multiple industries. Through meticulous manufacturing processes and a commitment to quality, these factories contribute to the success of various applications, from construction to agriculture and crafting. As they continue to innovate and adapt to changing market demands, the future of black annealed soft wire manufacturing looks promising, securing its place as a cornerstone in the wire industry.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

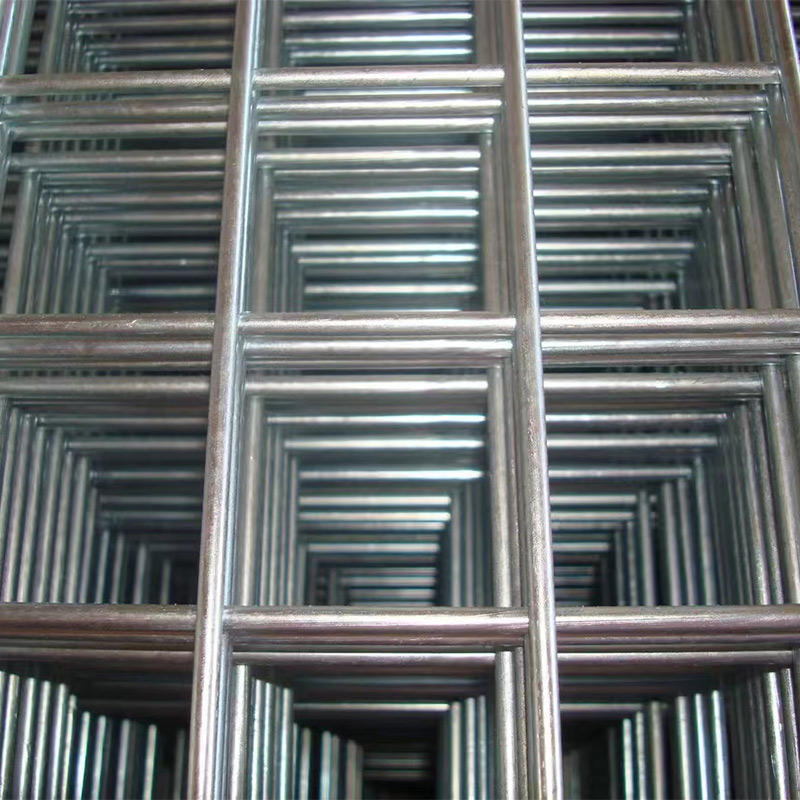

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025