12월 . 27, 2024 06:20 Back to list

cold drawn flat steel supplier

The Importance of Cold Drawn Flat Steel and Choosing the Right Supplier

Cold drawn flat steel is an essential material in various industries, offering significant advantages in terms of strength, precision, and versatility. This process involves the drawing of steel into flat shapes at room temperature, which enhances its mechanical properties and surpasses those of hot-rolled steel. In this article, we will delve into the characteristics of cold drawn flat steel, its applications, and the importance of choosing the right supplier to ensure quality and satisfaction.

Characteristics of Cold Drawn Flat Steel

Cold drawn flat steel is recognized for its superior dimensional accuracy and surface finish compared to other forms of steel. The cold drawing process significantly reduces the size of the steel, resulting in a denser, tougher material that possesses enhanced yield strength and fatigue resistance. This makes cold drawn flat steel particularly suitable for applications where precision and durability are paramount.

Additionally, the controlled manufacturing process allows for tighter tolerances. This level of precision ensures that components fit perfectly in various assemblies, reducing the need for additional machining or adjustments during fabrication. The smooth surface finish also improves the aesthetics of the final products, making cold drawn flat steel a preferred choice in industries where appearance matters, such as automotive and decorative applications.

Applications of Cold Drawn Flat Steel

Cold drawn flat steel has a wide range of applications across different sectors. In the automotive industry, it is commonly used for manufacturing components such as brackets, panels, and beams. The aviation industry also benefits from this material for parts that require high strength-to-weight ratios. Moreover, it is widely utilized in construction, where structural components need to endure significant loads while maintaining a lightweight form.

Other notable applications include the production of hydraulic cylinders, axles, and conveyor systems. Furthermore, cold drawn flat steel is often used in the creation of tool and die manufacturing, where high precision plays a crucial role in ensuring the functionality of the end products.

Choosing the Right Supplier

cold drawn flat steel supplier

When it comes to sourcing cold drawn flat steel, the choice of supplier can significantly impact the success of your projects. Here are several key factors to consider when selecting a supplier

1. Quality Assurance Look for suppliers that adhere to strict quality control processes. Certifications such as ISO 9001 indicate a commitment to maintaining high manufacturing standards. A reliable supplier will be transparent about their quality assurance checks and will provide documentation to back their claims.

2. Range of Products A good supplier should offer a variety of cold drawn flat steel products in different grades and dimensions. This versatility allows you to find the exact specifications you need for your projects without having to source multiple suppliers.

3. Customer Service Excellent customer support is vital when dealing with suppliers. Choose a supplier who is responsive, knowledgeable, and willing to provide assistance throughout the ordering process. They should be able to guide you in selecting the right products based on your requirements and ensure timely delivery.

4. Reputation and Experience Consider the longevity and reputation of the supplier in the industry. A supplier with extensive experience is likely to have a better understanding of market needs and cutting-edge manufacturing techniques, providing you with confidence in their products.

5. Pricing and Terms While pricing shouldn't be the only determining factor, it's essential to evaluate the cost of materials in conjunction with their quality. Competitive pricing with favorable terms can significantly impact your overall project budgets.

Conclusion

Cold drawn flat steel is a vital component in many industrial applications, delivering unmatched strength and precision. By carefully choosing a reputable supplier, you can ensure that you receive high-quality materials that will meet the demands of your projects. In the ever-evolving landscape of industry, the right supplier can be a critical partner in your success, enabling you to achieve superior results in your manufacturing processes.

-

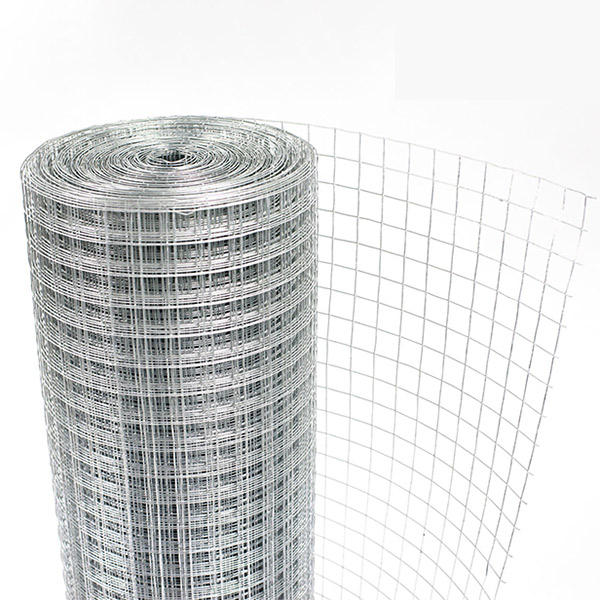

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025