ನವೆಂ . 27, 2024 10:51 Back to list

Cold Drawn Spring Wire Manufacturing Process and Quality Standards Explained

The Importance of Cold Drawn Spring Wire in Modern Manufacturing

Cold drawn spring wire plays a vital role in various industries, including automotive, aerospace, electronics, and general manufacturing. This specialized wire is essential for creating high-performance springs and components that require reliability and precision. The process of cold drawing not only enhances the mechanical properties of the wire but also ensures that it meets stringent industry standards for performance and durability.

Understanding Cold Drawing

Cold drawing is a process in which wire is pulled through a series of dies at room temperature, resulting in a reduction of its diameter and an increase in its length. This method enables manufacturers to achieve specific tolerances and mechanical properties that hot-rolled products cannot provide. The process involves several stages it begins with the selection of the right raw material, usually carbon steel or stainless steel, which is then meticulously drawn to achieve the desired diameter.

The cold drawing process imparts several advantageous properties to the wire. It increases tensile strength, enhances surface finish, and improves ductility. These characteristics are crucial for applications where high fatigue resistance and elastic limits are required, such as in the production of springs.

Applications of Cold Drawn Spring Wire

The versatility of cold drawn spring wire makes it suitable for various applications. In the automotive industry, it is used to manufacture components like valve springs, clutch springs, and suspension springs, all of which are critical for the performance and safety of vehicles. In the aerospace sector, cold drawn wire is employed in landing gear assemblies and other mechanical parts that must withstand extreme conditions and stresses.

Moreover, electronics manufacturers rely on cold drawn spring wire for creating connectors, switches, and other components where precision and reliability are essential

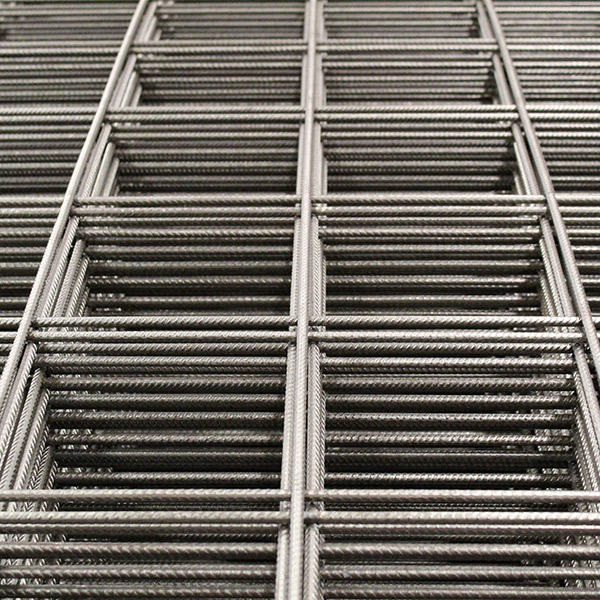

. Additionally, the construction industry utilizes this wire in producing reinforcement bars and various structural elements that require high tensile strength.cold drawn spring wire factory

Quality Control in Manufacturing

A reputable cold drawn spring wire factory places a strong emphasis on quality control throughout the production process. This involves rigorous testing of raw materials and finished products, including assessments for tensile strength, elongation, and surface quality. Quality assurance protocols are in place to ensure that the wire meets relevant industry standards, such as ISO and ASTM specifications.

Moreover, the manufacturing process must adhere to strict environmental and safety regulations. Factories invest in modern technology and equipment to minimize waste, reduce energy consumption, and enhance the overall efficiency of the production process. This commitment to sustainability is not only beneficial for the environment but also enhances the competitive edge of manufacturers in the global market.

Strategic Partnerships and Innovation

To stay ahead in the ever-evolving landscape of manufacturing, cold drawn spring wire factories often form strategic partnerships with their clients. By collaborating closely, manufacturers gain insights into market trends and advancements in material science. This collaboration allows them to innovate and adapt their products to meet the changing needs of their customers.

Investment in research and development is crucial for pushing the boundaries of what cold drawn spring wire can achieve. Advancements in wire coatings and treatments can further enhance the performance of the wire in specific applications, leading to longer product lifespans and reduced maintenance needs.

Conclusion

Cold drawn spring wire is indispensable in today’s manufacturing landscape, playing a critical role in enhancing the performance and longevity of various components. As industries continue to demand higher quality and more resilient materials, manufacturers must adhere to stringent quality controls and invest in innovative practices. By doing so, cold drawn spring wire factories ensure they remain vital contributors to advancements in multiple sectors, ultimately driving progress in technology and engineering. The future of manufacturing will undoubtedly continue to depend on the reliable performance of materials like cold drawn spring wire, making its role more crucial than ever.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025