តុលា . 02, 2024 09:16 Back to list

Wholesale Hot Dip Galvanized Steel Grating for Strong and Durable Flooring Solutions

Wholesale Hot Dip Galvanized Steel Grating An Overview

Hot dip galvanized steel grating has become increasingly popular in various industries due to its durability, versatility, and cost-effectiveness. This article explores the features, benefits, and applications of wholesale hot dip galvanized steel grating, providing insights into why this material is in demand among manufacturers and contractors.

What is Hot Dip Galvanized Steel Grating?

Hot dip galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. The process entails immersing the steel grating into a bath of molten zinc, resulting in a strong adherence of the zinc to the steel surface. This protective layer is crucial in extending the lifespan of the grating, making it resistant to rust and degradation, especially in harsh environmental conditions.

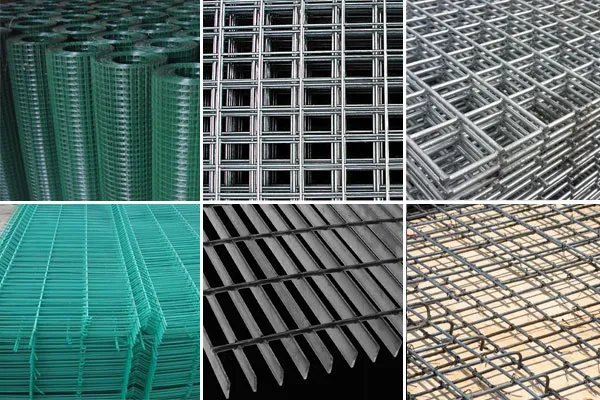

Steel grating is typically fabricated from steel bars, forming a grid-like structure that provides excellent load-bearing capabilities. The combination of the grating’s design and hot dip galvanization results in a robust product that can support heavy loads while allowing for adequate drainage and ventilation.

Advantages of Hot Dip Galvanized Steel Grating

1. Corrosion Resistance The primary advantage of hot dip galvanized steel grating is its exceptional resistance to corrosion. The zinc coating acts as a barrier, preventing moisture and corrosive elements from reaching the steel underneath, which is particularly valuable in environments prone to rust.

2. Longevity With proper installation and maintenance, hot dip galvanized steel grating can last for decades. This longevity translates into lower replacement costs and reduced maintenance efforts, making it an economical choice over time.

wholesale hot dip galvanized steel grating

3. Strength and Load Bearing Steel grating offers high strength and load-bearing capacities, making it suitable for various applications, including walkways, platforms, and industrial flooring. The open design of the grating allows for effective weight distribution.

4. Versatility Hot dip galvanized steel grating is available in various sizes, patterns, and configurations to meet different project requirements. Whether you need lightweight panels for pedestrian walkways or heavy-duty grating for industrial use, there is a suitable option available.

5. Aesthetic Appeal The clean and uniform appearance of galvanized steel grating can enhance the aesthetic appeal of a facility. It is suitable for both industrial settings and architectural applications.

Applications of Hot Dip Galvanized Steel Grating

Hot dip galvanized steel grating has a wide range of applications across various industries, including

- Construction Used for flooring, walkways, and stair treads, providing safe and slip-resistant surfaces. - Water Treatment Facilities Ideal for use in sewage treatment plants and water treatment facilities due to its corrosion resistance and ability to withstand harsh chemicals. - Petrochemical Industry Suitable for platforms, catwalks, and trench covers where exposure to chemicals and petroleum products is common. - Mining Often used in mines for walkways and platforms due to its strength and load capacity. - Parks and Recreational Areas Utilized in the construction of footbridges, decks, and observation platforms to ensure safety and durability.

Conclusion

In summary, wholesale hot dip galvanized steel grating serves as an essential component in various applications, providing durability, safety, and aesthetic appeal. Its resistance to corrosion, strength, and longevity make it a preferred choice among contractors and engineers. As industries continue to seek efficient and reliable materials, the demand for galvanized steel grating is expected to grow, reinforcing its position as a staple in construction and manufacturing sectors. Whether for industrial, commercial, or recreational use, hot dip galvanized steel grating proves to be a cost-effective and efficient solution for a multitude of applications.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025