ធ្នូ . 18, 2024 07:08 Back to list

welding steel mesh factory

The Importance of Welding Steel Mesh in Industrial Applications

Welding steel mesh has become an integral process in various industrial sectors, due to its versatility, strength, and efficiency. As industries continue to evolve and expand, the demand for durable and reliable materials, including steel mesh, has grown significantly. In this article, we will explore the various aspects of steel mesh production, its applications, and the benefits it offers in different fields.

Understanding Steel Mesh

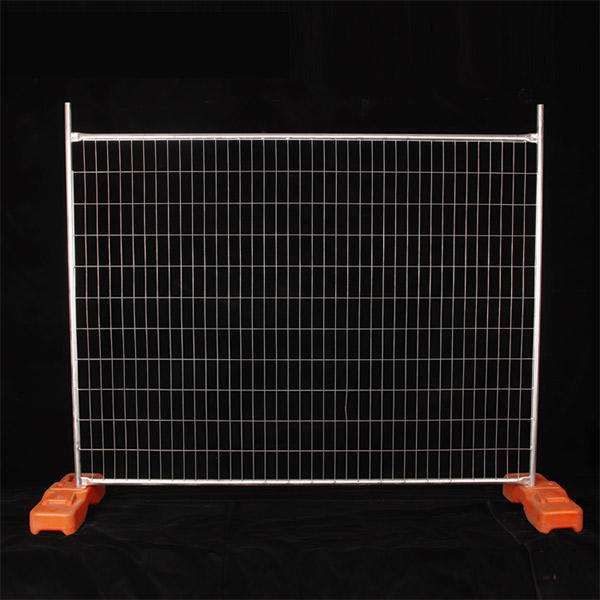

Steel mesh is composed of steel wires that are welded together in a grid-like pattern. The key characteristics of steel mesh include durability, tensile strength, and resistance to corrosion. This makes it suitable for a wide range of applications, including construction, agriculture, and manufacturing. The manufacturing process involves precise welding techniques, ensuring that each join is secure and reliable.

Welding Techniques

The welding of steel mesh involves various techniques, each suitable for different applications. Common methods include spot welding, arc welding, and resistance welding. Spot welding is often used for joining two overlapping wires at specific points, providing strong connections without the need for additional materials. Arc welding, on the other hand, uses an electric arc to melt the wires together, creating a fusion that offers exceptional strength. Resistance welding is known for its efficiency and speed, particularly in high-volume production environments.

Applications of Steel Mesh

One of the primary applications of welded steel mesh is in construction. It is frequently used for reinforcement in concrete slabs, walls, and foundations. By incorporating steel mesh into concrete structures, engineers can enhance the tensile strength and load-bearing capacity, reducing the likelihood of cracking and structural failure. Additionally, steel mesh is preferred for its ability to distribute loads evenly, thereby increasing the overall stability of the construction.

welding steel mesh factory

In agriculture, welded steel mesh is employed for fencing, cages, and support structures for various crops. Its strength and durability ensure that it can withstand environmental stresses, providing protection for livestock and crops alike. The flexibility of the material also allows for a wide range of designs and applications, making it a popular choice among farmers and agricultural professionals.

Moreover, steel mesh finds extensive use in manufacturing processes. It is often utilized for creating filters, screens, and separators in mining, water treatment, and food processing industries. The ability to customize the size and shape of steel mesh according to specific requirements makes it an invaluable resource in these sectors.

Advantages of Welding Steel Mesh

The advantages of welding steel mesh are manifold. Firstly, it offers remarkable strength and durability, ensuring that the final product can withstand heavy loads and stresses. Secondly, the welding process creates a continuous structure without weak spots, enhancing the overall integrity of the mesh. Furthermore, steel mesh can be produced in various sizes and configurations, allowing for tailored solutions that meet the specific needs of diverse industries.

From a cost perspective, welded steel mesh is an economical choice. The efficient production processes reduce labor and material costs, making it an attractive option for large-scale projects. Moreover, the long service life and low maintenance requirements contribute to reduced long-term expenses.

Conclusion

In summary, the welding of steel mesh represents a critical process in various industrial applications. Its strength, versatility, and cost-effectiveness make it an indispensable material in construction, agriculture, and manufacturing. As technology advances, the processes for creating high-quality welded steel mesh will continue to improve, further enhancing its applications and benefits. Whether reinforcing concrete structures or providing solutions in agriculture, steel mesh remains a fundamental building block in modern industry, showcasing the importance of innovation in material science and engineering.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025