មករា . 14, 2025 10:07 Back to list

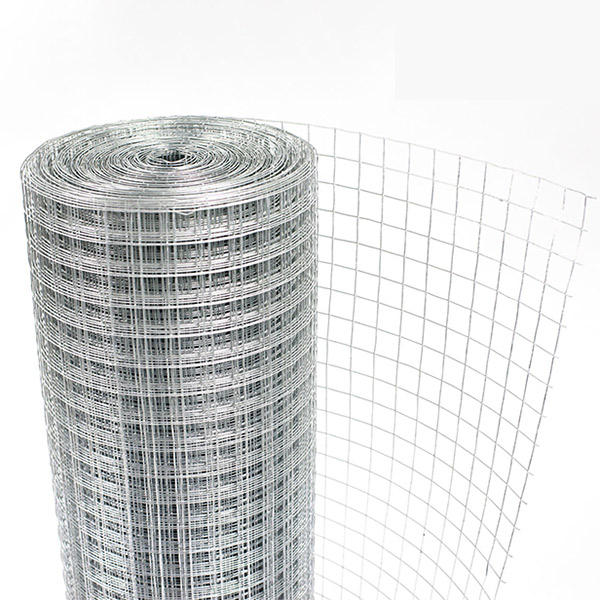

welded wire mesh for industry factories

Cold drawn spring wire is an essential component in various industries, appreciated for its exceptional strength and versatility. With decades of experience in the production and application of this vital material, I have witnessed its transformative impact on manufacturing processes and product reliability.

Authoritative knowledge in cold drawn spring wire is underpinned by continuous research and development. Leading manufacturers invest in state-of-the-art technology and innovations to improve wire characteristics such as strength-to-weight ratio and corrosion resistance. These advancements not only broaden the scope of applications but also contribute to sustainability by enabling the production of lighter, more efficient components. Trustworthiness in the context of cold drawn spring wire involves a commitment to quality control and customer satisfaction. Esteemed manufacturers are often those that prioritize transparency and clear communication, ensuring that clients are fully informed about specifications and potential applications. Moreover, adherence to international standards and certifications is a hallmark of a reputable producer, providing customers with the confidence that their products are both reliable and compliant with global industry norms. In conclusion, the cold drawn spring wire is much more than a simple component; it is a testament to advanced engineering and material science. With its unrivaled strength, precision, and adaptability, it plays a crucial role in numerous sectors, driving innovation and efficiency. Understanding the intricacies of its production and application is key to leveraging its full potential, making it an indispensable part of any project demanding durability and precision.

Authoritative knowledge in cold drawn spring wire is underpinned by continuous research and development. Leading manufacturers invest in state-of-the-art technology and innovations to improve wire characteristics such as strength-to-weight ratio and corrosion resistance. These advancements not only broaden the scope of applications but also contribute to sustainability by enabling the production of lighter, more efficient components. Trustworthiness in the context of cold drawn spring wire involves a commitment to quality control and customer satisfaction. Esteemed manufacturers are often those that prioritize transparency and clear communication, ensuring that clients are fully informed about specifications and potential applications. Moreover, adherence to international standards and certifications is a hallmark of a reputable producer, providing customers with the confidence that their products are both reliable and compliant with global industry norms. In conclusion, the cold drawn spring wire is much more than a simple component; it is a testament to advanced engineering and material science. With its unrivaled strength, precision, and adaptability, it plays a crucial role in numerous sectors, driving innovation and efficiency. Understanding the intricacies of its production and application is key to leveraging its full potential, making it an indispensable part of any project demanding durability and precision.

Latest news

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025