មករា . 13, 2025 09:45 Back to list

Twisted Square Bar

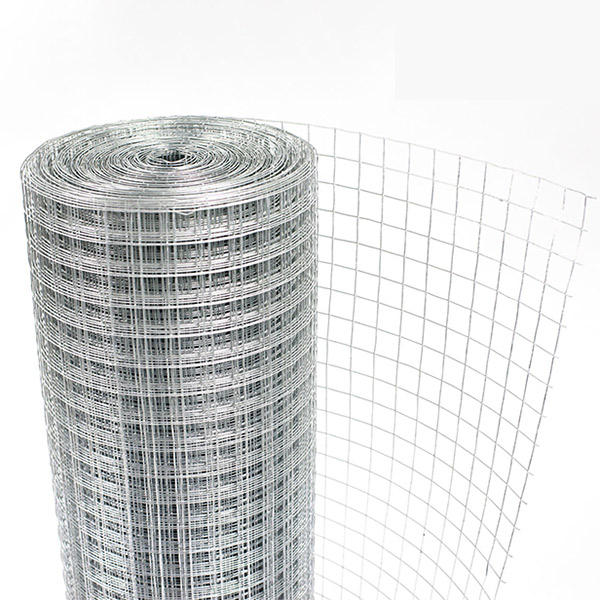

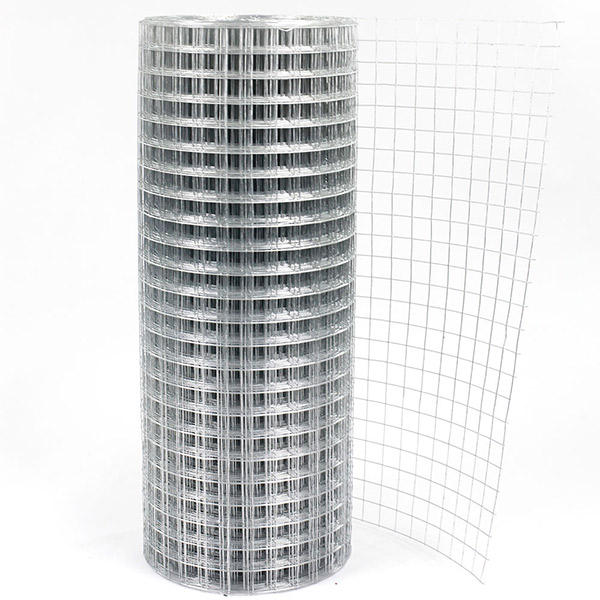

Reinforcing mesh, an essential component in modern construction, plays a pivotal role in enhancing the structural integrity and longevity of buildings. This article elucidates the various aspects of reinforcing mesh, ensuring that construction professionals comprehend its profound impact on building safety and durability.

Case studies have demonstrated the trustworthiness and efficacy of reinforcing mesh. Take, for instance, the reconstruction of earthquake-damaged structures where reinforcing mesh was integral to restoring buildings to a condition that not only met but exceeded safety standards. Such instances reinforce the trust that construction professionals place in this tool, acknowledging its capacity to transform architectural designs into resilient structures. Moreover, the experience of seasoned construction managers highlights the practical benefits of reinforcing mesh, such as reduced labor costs and time efficiency. By incorporating prefabricated mesh panels, workers can expedite the installation process, thus mitigating project delays and enhancing productivity on construction sites. Incorporating reinforcing mesh isn't just about ticking regulatory checkboxes; it's about investing in the longevity and safety of structures. As a product category, reinforcing mesh represents an indispensable resource for achieving cutting-edge construction that meets the demands of modern-day architecture. Innovations in material science are continually expanding the capabilities of reinforcing mesh, offering even lighter and more versatile options for construction professionals. The journey of a construction project from conception to completion is fraught with challenges, but the choice of reinforcing mesh should not be one of them. By prioritizing quality and compliance, professionals can ensure that their projects stand the test of time, embodying a blend of human ingenuity and industrial strength. Reinforcing mesh, with its profound experience-backed usage, expert-supported applications, authoritative mandates, and trusted dependability, remains a cornerstone of any successful building endeavor.

Case studies have demonstrated the trustworthiness and efficacy of reinforcing mesh. Take, for instance, the reconstruction of earthquake-damaged structures where reinforcing mesh was integral to restoring buildings to a condition that not only met but exceeded safety standards. Such instances reinforce the trust that construction professionals place in this tool, acknowledging its capacity to transform architectural designs into resilient structures. Moreover, the experience of seasoned construction managers highlights the practical benefits of reinforcing mesh, such as reduced labor costs and time efficiency. By incorporating prefabricated mesh panels, workers can expedite the installation process, thus mitigating project delays and enhancing productivity on construction sites. Incorporating reinforcing mesh isn't just about ticking regulatory checkboxes; it's about investing in the longevity and safety of structures. As a product category, reinforcing mesh represents an indispensable resource for achieving cutting-edge construction that meets the demands of modern-day architecture. Innovations in material science are continually expanding the capabilities of reinforcing mesh, offering even lighter and more versatile options for construction professionals. The journey of a construction project from conception to completion is fraught with challenges, but the choice of reinforcing mesh should not be one of them. By prioritizing quality and compliance, professionals can ensure that their projects stand the test of time, embodying a blend of human ingenuity and industrial strength. Reinforcing mesh, with its profound experience-backed usage, expert-supported applications, authoritative mandates, and trusted dependability, remains a cornerstone of any successful building endeavor.

Next:

Latest news

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025