ធ្នូ . 28, 2024 22:44 Back to list

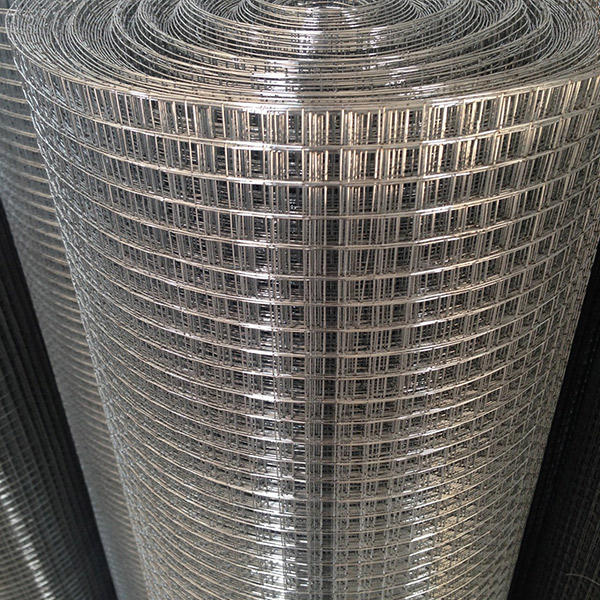

oem welded wire mesh 50x50

The Versatility and Applications of OEM Welded Wire Mesh 50x50

Welded wire mesh, a popular and versatile material used in various industries, is manufactured through a process that involves welding wires together to create a grid-like structure. Among the many sizes and configurations available, the 50x50 (50mm x 50mm) welded wire mesh stands out due to its balance of strength, flexibility, and utility. With the rise of OEM (Original Equipment Manufacturer) products, the demand for customized welded wire mesh has surged, offering tailored solutions to meet specific customer needs.

Understanding Welded Wire Mesh

Welded wire mesh is made from intersecting wires that are welded together at their points of contact. This formation creates a uniform grid pattern that is both durable and stable. Typically fabricated from high-quality steel or stainless steel, it can also be coated with different materials for added protection against corrosion and wear. The 50x50 mm grid size offers a balance between visibility and strength, making it suitable for a variety of applications.

Key Characteristics of OEM Welded Wire Mesh 50x50

1. Durability The welding process provides a strong bond that ensures the mesh can withstand significant weight and stress, making it ideal for heavy-duty applications.

2. Customizability As an OEM product, woven wire mesh can be tailored in terms of wire diameter, coating, and overall dimensions to meet specific client requirements. Whether used in construction, agriculture, or manufacturing, custom solutions provide targeted benefits.

3. Versatility The 50x50 grid size is particularly effective in a range of scenarios, from reinforcement in concrete structures to the creation of enclosures and partitions. Its versatility makes it a staple in various sectors, including construction, farming, landscaping, and even in artistic applications.

4. Ease of Installation Welded wire mesh is typically easy to install. It can be cut to size with standard tools, which allows contractors and DIY enthusiasts to work efficiently without requiring specialized equipment.

Applications of 50x50 Welded Wire Mesh

oem welded wire mesh 50x50

The applications of OEM welded wire mesh with a 50x50 grid structure are vast and varied

1. Construction Industry In the construction sector, welded wire mesh serves as reinforcement for concrete slabs, walls, and pavements. The 50x50 design provides excellent load distribution, making structures more resilient against cracking and deformation.

2. Agricultural Uses In agriculture, this mesh type is commonly used for fencing livestock enclosures, protecting crops from wildlife, and creating trellises for climbing plants. Its robust structure ensures longevity, especially in outdoor environments.

3. Industrial Applications The manufacturing of equipment and safety enclosures often involves welded wire mesh. The 50x50 configuration provides enhanced visibility while maintaining strength, making it suitable for machine guards, cages, and racks.

4. Erosion Control and Landscaping Welded wire mesh can be used in landscaping projects to stabilize soil and prevent erosion, particularly on slopes. It’s also effective in creating decorative elements like fencing and garden borders.

5. Arts and Crafts Artists and designers have begun to utilize welded wire mesh in creative ways, incorporating it into sculptures and installations due to its aesthetic appeal and structural properties.

Sustainability and Cost-Effectiveness

In recent years, there has been a growing emphasis on sustainability within the manufacturing sector. OEM welded wire mesh can be produced using recycled materials, contributing to an eco-friendly approach. Moreover, its durability means less frequent replacements, leading to long-term cost savings for businesses and consumers alike.

Conclusion

OEM welded wire mesh 50x50 is more than just a product; it represents a solution to various structural and functional challenges across multiple industries. Its strength, versatility, and customization options make it an invaluable resource, whether in construction, agriculture, or creative projects. As industries continue to evolve, the demand for high-quality, reliable materials like welded wire mesh will undoubtedly remain strong, making it a fundamental component in both everyday applications and specialized uses. Embracing this material not only supports innovation but also encourages a sustainable approach to manufacturing and resource management.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025