ធ្នូ . 20, 2024 19:41 Back to list

oem twisted bars for grating welding

The Evolution of OEM Twisted Bars for Grating Welding

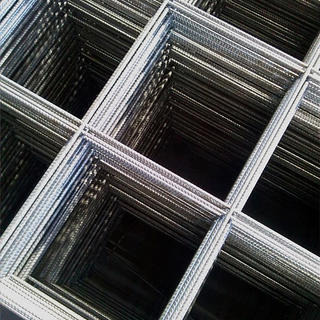

In the domain of industrial applications, the significance of grating systems cannot be overstated. Grating serves as a critical component in various settings, from walkways to drainage systems, where safety and strength are paramount. A notable contributor to the development of these systems is OEM (Original Equipment Manufacturer) twisted bars. These twisted bars are engineered specifically for grating welding, providing enhanced performance characteristics that meet the stringent demands of modern construction and manufacturing.

Understanding OEM Twisted Bars

OEM twisted bars are steel bars that undergo a unique twisting process to enhance their physical properties. This twisting not only increases the tensile strength of the bars but also improves their overall grip and bonding capabilities when used in grating applications. The increase in surface area due to the twisted design allows for better adhesion during the welding process, ensuring that the grating remains sturdy and secure over time.

The manufacturing process of these twisted bars involves precision engineering techniques that take into account the end use of the bars. OEMs focus on producing high-quality materials that conform to specific standards and requirements, making them an ideal choice for industries that demand reliability and durability. Whether used in heavy industrial settings or lighter commercial applications, OEM twisted bars are designed to withstand considerable stress and environmental factors.

Applications and Benefits

The applications of OEM twisted bars are extensive. They are commonly used in the construction of industrial flooring, pedestrian walkways, and drainage covers, among others. Their design allows for the creation of grating systems that not only resist deformation but also facilitate the efficient drainage of water, thereby preventing the accumulation of hazardous conditions.

One of the primary benefits of using OEM twisted bars in grating welding is their enhanced strength-to-weight ratio. This characteristic allows for lighter grating structures without compromising on load-bearing capabilities. Consequently, industries can take advantage of reduced material costs and simpler installation processes while still adhering to safety standards.

Moreover, twisted bars exhibit superior resistance to corrosion, particularly when coated with protective finishes. In environments exposed to moisture and chemicals, this resistance is crucial for the longevity and functionality of grating systems. OEM twisted bars can be manufactured from galvanized steel or stainless steel, further increasing their suitability for specific applications.

oem twisted bars for grating welding

Welding Process and Techniques

The welding process for grating systems that utilize OEM twisted bars is a critical aspect of their performance. The twisted design enhances the weldability of the bars, allowing for more robust joints. Various welding techniques, such as spot welding, TIG (Tungsten Inert Gas) welding, or MIG (Metal Inert Gas) welding, can be employed depending on the specific requirements of the project.

In practice, the welding process begins with careful alignment of the twisted bars to ensure uniformity and strength. Technicians skilled in the art of welding employ precision equipment to achieve consistent results, minimizing the risk of defects. The interaction between the twisted surface of the bars and the welding apparatus is a focal point of innovation, as advancements in technology continue to improve the efficiency and effectiveness of the welding process.

Sustainability and Future Trends

As industries grow increasingly aware of their environmental impact, OEMs are exploring sustainable practices in the production of twisted bars. This includes sourcing raw materials responsibly, minimizing waste during manufacturing, and developing recycling initiatives for end-of-life products. The emphasis on sustainability is not only good for the planet but also appeals to environmentally conscious consumers and businesses alike.

Looking ahead, the future of OEM twisted bars for grating welding is bright. With advancements in materials science and welding technology, these bars are likely to become even more efficient and versatile. Emerging trends such as smart materials and automated welding processes promise to revolutionize how grating systems are designed and implemented.

Conclusion

In summary, OEM twisted bars represent a significant advancement in the field of grating welding. Through meticulous engineering and innovative design, these bars offer enhanced durability, strength, and versatility, making them an invaluable asset across various industries. As technology continues to evolve, the potential for these components to adapt and meet future challenges remains substantial, ensuring their place at the forefront of industrial applications for years to come.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025