កុម្ភៈ . 15, 2025 22:11 Back to list

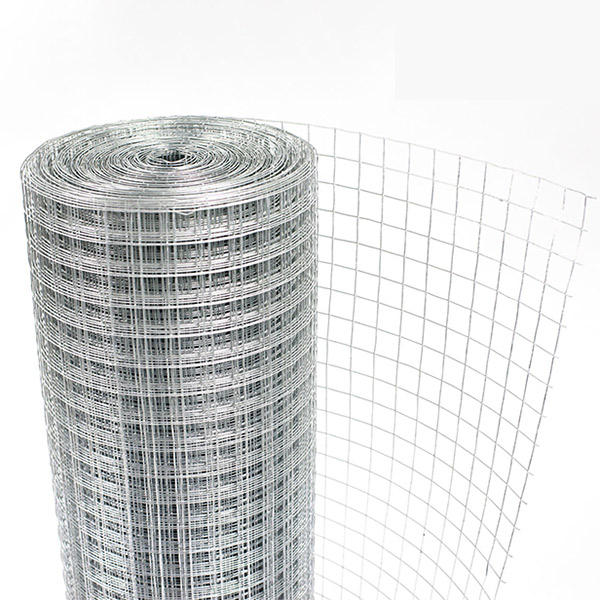

welded wire mesh for industry factories

Navigating the world of OEM steel wire mesh pricing involves understanding a myriad of factors that influence market dynamics. This guide not only demystifies the various elements contributing to the cost of steel wire mesh but also serves as an authoritative source for businesses keen on optimizing procurement strategies in this sector. Let's delve into the intricacies of steel wire mesh pricing, supported by real-world insights and expert knowledge.

Customization requirements can increase the price of steel wire mesh. Clients often require specific designs, sizes, or material compositions to meet unique project needs. Custom orders require adjustments in the production line, resulting in additional setup time and costs. Experts recommend clearly defining specifications and communicating them early in the procurement process to minimize unexpected expenses. Collaborating directly with experienced manufacturers can lead not only to cost savings but also to superior product quality and alignment with project goals. The global supply chain has its share of challenges that impact steel wire mesh pricing, such as tariffs, trade policies, and transportation issues. Events like trade negotiations or disruptions can alter pricing structures significantly. Seasoned professionals in the field advise maintaining an adaptable procurement strategy, allowing businesses to pivot quickly in response to sudden market changes. Building a network of reliable suppliers can provide the necessary flexibility to mitigate these risks. By applying a strategic approach, businesses can navigate the complex landscape of OEM steel wire mesh pricing effectively. Understanding raw material costs, manufacturing processes, geographic factors, bulk purchasing benefits, customization demands, and supply chain intricacies enables companies to make informed procurement decisions. Trust in industry expertise, combined with real-world experience, can transform these challenges into opportunities for optimized expenditure and enhanced market positioning. Ultimately, developing a thorough understanding of these elements will empower companies to make strategic decisions that foster long-term profitability and competitiveness in the marketplace. Investing in expertise and continuously assessing market conditions ensures that businesses remain agile, adapting to changes with confidence and authority.

Customization requirements can increase the price of steel wire mesh. Clients often require specific designs, sizes, or material compositions to meet unique project needs. Custom orders require adjustments in the production line, resulting in additional setup time and costs. Experts recommend clearly defining specifications and communicating them early in the procurement process to minimize unexpected expenses. Collaborating directly with experienced manufacturers can lead not only to cost savings but also to superior product quality and alignment with project goals. The global supply chain has its share of challenges that impact steel wire mesh pricing, such as tariffs, trade policies, and transportation issues. Events like trade negotiations or disruptions can alter pricing structures significantly. Seasoned professionals in the field advise maintaining an adaptable procurement strategy, allowing businesses to pivot quickly in response to sudden market changes. Building a network of reliable suppliers can provide the necessary flexibility to mitigate these risks. By applying a strategic approach, businesses can navigate the complex landscape of OEM steel wire mesh pricing effectively. Understanding raw material costs, manufacturing processes, geographic factors, bulk purchasing benefits, customization demands, and supply chain intricacies enables companies to make informed procurement decisions. Trust in industry expertise, combined with real-world experience, can transform these challenges into opportunities for optimized expenditure and enhanced market positioning. Ultimately, developing a thorough understanding of these elements will empower companies to make strategic decisions that foster long-term profitability and competitiveness in the marketplace. Investing in expertise and continuously assessing market conditions ensures that businesses remain agile, adapting to changes with confidence and authority.

Latest news

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025