កុម្ភៈ . 15, 2025 21:34 Back to list

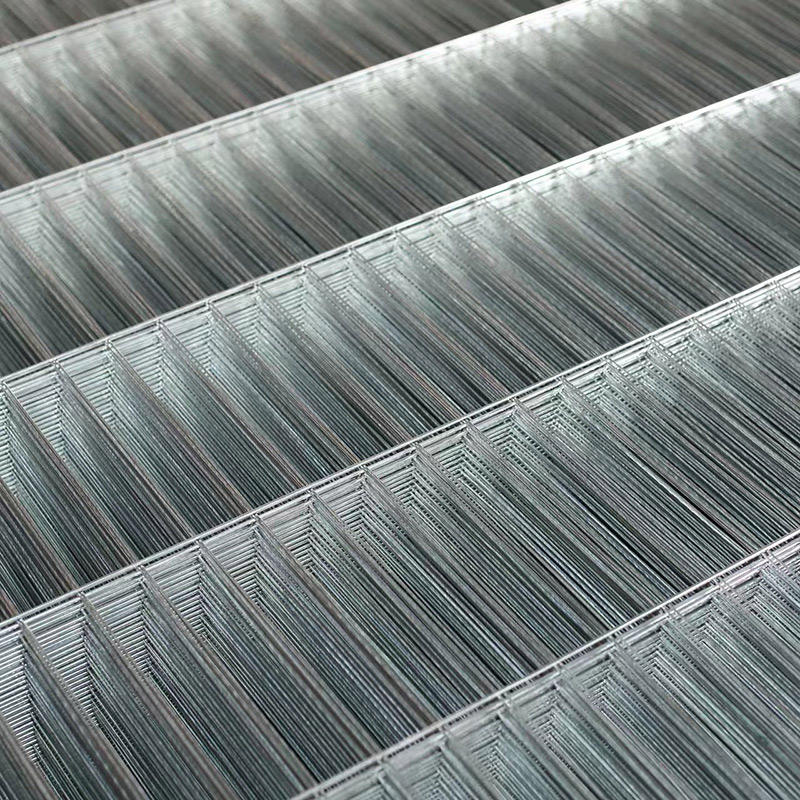

welded wire mesh for industry factories

In the construction industry, achieving structural integrity and durability is paramount. Steel concrete reinforcement wire mesh, commonly used in large-scale projects, offers unparalleled advantages in reinforcing concrete structures such as slabs, walls, and foundations. Here, I’ll share insights drawn from my extensive experience to highlight why OEM steel concrete reinforcement wire mesh stands out in the market today.

Furthermore, adopting OEM steel wire mesh contributes significantly to project timelines. The ease of installation translates to reduced labor hours. Prefabricated mesh sheets expedite the construction process by eliminating the need for manual binding of steel bars on site. Professionals appreciate that these meshes provide a faster, more uniform reinforcement application, enhancing both the appearance and effectiveness of the finished concrete. Stakeholders in the construction industry trust OEM-produced steel wire meshes not just for their structural benefits, but also for adhering to environmental standards. Many OEMs are committed to sustainable manufacturing practices, utilizing recyclable materials and efficient production methods to minimize the carbon footprint associated with steel manufacturing. Trust in OEM reinforcement products also stems from rigorous testing and certification. Compliance with international safety standards, such as ASTM or ISO certifications, is a testament to the mesh’s quality and assures stakeholders of its performance under varied environmental conditions. Finally, it’s vital to emphasize the role of authoritative recommendations in selecting the appropriate reinforcement mesh. Consulting materials from seasoned civil engineers and reputable construction researchers provides invaluable guidance. Being equipped with insights from authoritative sources enhances trust among clients and project collaborators, ultimately resulting in successful project outcomes. In conclusion, OEM steel concrete reinforcement wire mesh distinguishes itself through its robust, versatile application in reinforcing concrete structures. Its benefits, ranging from customization and operational efficiency to sustainability and trustworthiness, position it as an indispensable tool in the modern construction repertoire. By prioritizing the integration of OEM steel wire mesh, professionals ensure that they are employing highly qualified, reliable, and sustainable solutions tailored to meet the dynamic demands of contemporary architecture and engineering projects.

Furthermore, adopting OEM steel wire mesh contributes significantly to project timelines. The ease of installation translates to reduced labor hours. Prefabricated mesh sheets expedite the construction process by eliminating the need for manual binding of steel bars on site. Professionals appreciate that these meshes provide a faster, more uniform reinforcement application, enhancing both the appearance and effectiveness of the finished concrete. Stakeholders in the construction industry trust OEM-produced steel wire meshes not just for their structural benefits, but also for adhering to environmental standards. Many OEMs are committed to sustainable manufacturing practices, utilizing recyclable materials and efficient production methods to minimize the carbon footprint associated with steel manufacturing. Trust in OEM reinforcement products also stems from rigorous testing and certification. Compliance with international safety standards, such as ASTM or ISO certifications, is a testament to the mesh’s quality and assures stakeholders of its performance under varied environmental conditions. Finally, it’s vital to emphasize the role of authoritative recommendations in selecting the appropriate reinforcement mesh. Consulting materials from seasoned civil engineers and reputable construction researchers provides invaluable guidance. Being equipped with insights from authoritative sources enhances trust among clients and project collaborators, ultimately resulting in successful project outcomes. In conclusion, OEM steel concrete reinforcement wire mesh distinguishes itself through its robust, versatile application in reinforcing concrete structures. Its benefits, ranging from customization and operational efficiency to sustainability and trustworthiness, position it as an indispensable tool in the modern construction repertoire. By prioritizing the integration of OEM steel wire mesh, professionals ensure that they are employing highly qualified, reliable, and sustainable solutions tailored to meet the dynamic demands of contemporary architecture and engineering projects.

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025