វិច្ឆិកា . 27, 2024 04:02 Back to list

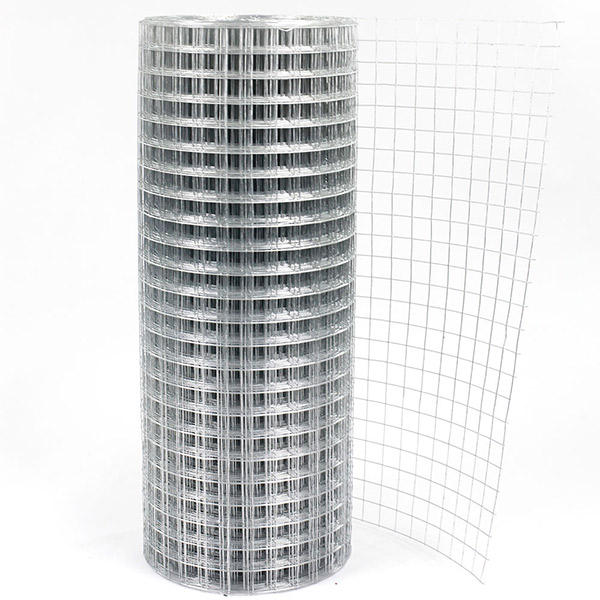

GI Welded Wire Mesh Manufacturing Reliable Solutions for Your Needs

The Importance of GI Welded Wire Mesh Factories

In today's rapidly advancing industrial landscape, one of the pivotal components that significantly enhances the structural integrity of various constructions is the galvanized iron (GI) welded wire mesh. This versatile material is widely utilized in several applications, including construction, agriculture, and fencing, making the factories that produce GI welded wire mesh a crucial part of the manufacturing sector.

Understanding GI Welded Wire Mesh

Galvanized iron welded wire mesh is made from wires coated with zinc to prevent corrosion, thereby enhancing durability and longevity. The process of welding the wires together creates a strong and stable network, which provides excellent support and form. This construction improves the mesh's ability to bear loads and resist environmental factors, making it an ideal choice for a multitude of applications.

The Manufacturing Process

GI welded wire mesh factories employ advanced technology and skilled labor to produce high-quality wire mesh products. The manufacturing process begins with the selection of raw materials, typically high-quality galvanized iron wire. The wires are then cut to specific lengths and arranged in a predetermined pattern. Using specialized welding machines, the wires are fused together at intersecting points, creating a robust mesh.

Once welded, the mesh undergoes inspections to ensure compliance with industry standards. Quality control is a critical aspect of the manufacturing process, as it ensures that the final product meets the required specifications for strength, flexibility, and resistance to rusting. Some factories may also offer additional coatings or treatments to enhance the mesh's properties further.

Applications of GI Welded Wire Mesh

The applications of GI welded wire mesh are extensive. In the construction industry, it is commonly used as reinforcement in concrete structures, providing added strength and preventing cracking. The mesh can be found in walls, ceilings, and floors, ensuring stability in various architectural designs.

gi welded wire mesh factories

In agriculture, GI welded wire mesh is utilized for fencing and enclosures to protect crops and livestock from predators. Its sturdy construction ensures that it can withstand harsh weather conditions while effectively containing animals within designated areas.

Additionally, GI welded wire mesh is used in various outdoor and indoor projects, such as garden trellises, safety barriers, and decorative elements. Its versatility makes it a preferred choice among architects and builders looking to combine functional strength with aesthetic appeal.

The Role of GI Welded Wire Mesh Factories in the Economy

GI welded wire mesh factories not only play a crucial role in the production of this indispensable material but also contribute significantly to the economy. By providing employment opportunities and fueling ancillary industries, these factories help stimulate local economies. Skilled workers are required to operate machinery, manage quality control, and handle logistics, leading to a demand for training and education in the manufacturing sector.

Moreover, as demand for sustainable building materials rises, factories producing eco-friendly GI welded wire mesh are becoming increasingly relevant. With a focus on reducing the environmental impact, these manufacturers are adopting sustainable practices, such as recycling scrap metal and minimizing energy consumption during production.

Challenges Faced by GI Welded Wire Mesh Factories

Despite their importance, GI welded wire mesh factories face several challenges. Fluctuating prices of raw materials, competition from imports, and the need for continuous innovation to meet evolving customer demands are just a few of the obstacles they encounter. Moreover, maintaining high-quality standards amid these challenges requires ongoing investment in technology and training.

Conclusion

In conclusion, GI welded wire mesh factories are essential to modern construction and agriculture, providing durable and reliable materials that meet diverse needs. Their contribution to the economy and commitment to sustainability highlight their significance in today's world. As the demand for innovative building solutions continues to grow, these factories will remain at the forefront, shaping the future of construction and reinforcing our infrastructures. Supporting local production through awareness and purchasing can help ensure that these factories thrive, continuing to provide high-quality products and employment opportunities for years to come.

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025

-

Black Annealed Wire Specification - High Quality & Custom Options from Leading Factories, Suppliers, Manufacturers

NewsJun.10,2025

-

High-Quality 18 Gauge Black Steel Wire Reliable Factories & Suppliers

NewsJun.10,2025

-

Chain Link Fence Gates - Durable & Secure Access Solutions

NewsJun.10,2025

-

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

NewsJun.10,2025

-

Galvanized Wire Brick Force Mesh - Corrosion Resistant

NewsJun.09,2025