ធ្នូ . 18, 2024 05:28 Back to list

BRC Welded Mesh Production Facilities Overview and Insights

The Rise of BRC Welded Mesh Factories A Comprehensive Overview

In the realm of construction and industrial applications, BRC welded mesh has emerged as a critical component in reinforcing concrete structures. As urbanization accelerates and infrastructure needs expand, the demand for high-quality welded mesh continues to grow, leading to the establishment of numerous BRC welded mesh factories worldwide. This article explores the significance, production processes, and benefits of BRC welded mesh, highlighting its essential role in modern construction.

Understanding BRC Welded Mesh

BRC welded mesh refers to a type of steel reinforcement mesh made from a series of interwoven wires that are electrically welded at each junction. The name BRC is derived from the brand that popularized this type of mesh, standing for British Reinforcement Company. This mesh serves various purposes, primarily in the construction of floors, roofs, and walls, where it provides tensile strength to concrete, allowing structures to withstand heavy loads and resist cracking.

Welded mesh comes in various sizes and configurations, tailored to specific project requirements. The standardized dimensions simplify the procurement and installation processes, making it a popular choice among contractors.

The Production Process

The manufacturing process of BRC welded mesh is intricate and highly automated. It begins with the selection of high-quality steel wire, which is then drawn into specific diameters. This wire is carefully inspected for defects to ensure it meets industry standards.

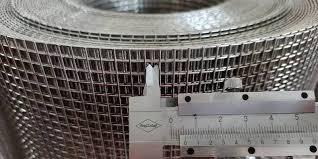

Next, the wires are arranged in a grid pattern, and advanced welding machines are employed to fuse the intersecting wires at each point. The welding process is crucial; it ensures that the mesh can withstand significant tension and compression forces. Once welded, the mesh is cut to size, spooled, and ready for packaging.

Quality control is a vital aspect of BRC welded mesh production. Manufacturers rigorously test the welded mesh for durability, tensile strength, and overall integrity. This commitment to quality ensures that the final product is not only reliable but also compliant with local and international construction standards.

brc welded mesh factories

Benefits of BRC Welded Mesh

BRC welded mesh offers numerous advantages that contribute to its widespread use in construction

1. Enhanced Structural Integrity The primary function of welded mesh is to reinforce concrete, improving the overall structural integrity of buildings. It effectively distributes loads and reduces the risk of cracks.

2. Cost-Effectiveness Compared to traditional reinforcement methods, BRC welded mesh can significantly reduce labor costs and installation time. Its ready-to-use format allows for quicker setup on-site, leading to faster project completion.

3. Versatility BRC welded mesh can be used in various applications, including residential, commercial, and industrial structures. Its adaptability makes it suitable for a wide range of construction projects, from flooring to precast panels.

4. Durability Made from high-quality steel, BRC welded mesh is resistant to corrosion and environmental factors when appropriately coated or treated. This longevity translates to lower maintenance costs for buildings over time.

5. Consistency and Reliability The automated production process of BRC welded mesh ensures that each batch is produced to consistent quality standards. This reliability is crucial for engineers and architects who rely on dependable materials for their designs.

Conclusion

As the global construction industry continues to evolve, BRC welded mesh factories are playing an essential role in meeting the increasing demand for high-quality reinforcement solutions. With its numerous benefits, including enhanced structural integrity, cost-effectiveness, and versatility, BRC welded mesh has become a staple in modern construction practices. As factories strive for innovation and improved production techniques, the future looks promising for BRC welded mesh and the industries that rely on it. Investing in advanced technology and sustainable practices will not only enhance the quality of the product but also contribute to a greener and more efficient construction landscape. It is safe to say that BRC welded mesh has firmly established itself as a crucial element in the building of robust, safe, and sustainable structures for the future.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025