ធ្នូ . 22, 2024 16:47 Back to list

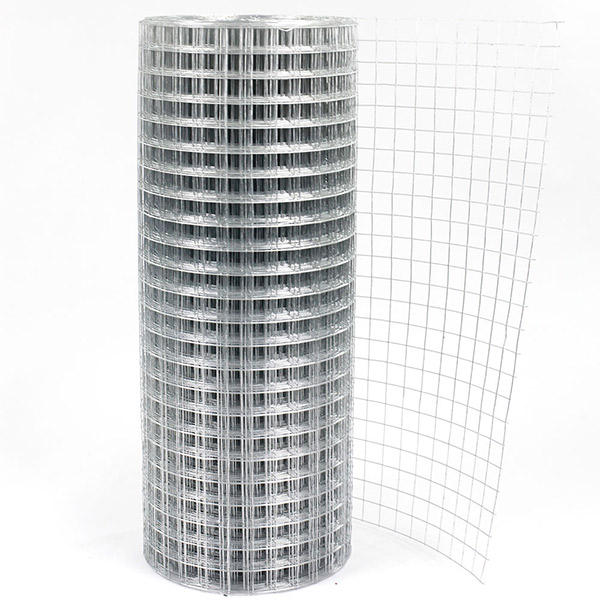

10mm steel bar welded wire mesh

The Importance of 10mm Steel Bar Welded Wire Mesh in Construction

In the realm of construction and civil engineering, the use of durable and reliable materials is paramount. One such material that has gained significant attention in recent years is the 10mm steel bar welded wire mesh. This versatile product plays a crucial role in enhancing the structural integrity of concrete structures, making it an indispensable element in various construction projects.

What is 10mm Steel Bar Welded Wire Mesh?

10mm steel bar welded wire mesh is a pre-fabricated reinforcement product made from high-quality steel bars, typically arranged in a grid pattern. The bars are welded at their intersections to create a robust and secure network. The 10mm designation refers to the diameter of the steel bars used, which offers a balance between strength and flexibility. This type of mesh can be produced in various sizes and configurations, allowing for customized solutions to meet specific engineering requirements.

Applications in Construction

The applications of 10mm steel bar welded wire mesh are diverse, spanning across residential, commercial, and infrastructural projects. It is primarily used to reinforce concrete slabs, walls, pavements, and foundations, enhancing their load-bearing capacity and longevity. By distributing loads evenly, the welded wire mesh minimizes the risk of cracking and deformation, ensuring that structures remain stable throughout their lifespan.

In residential construction, welded wire mesh is commonly employed in slab-on-grade foundations, where it acts as a barrier to control shrinkage and cracking. It is also used in driveways and sidewalks to improve surface integrity. In commercial and industrial applications, the mesh is crucial for creating strong and durable floors that can withstand heavy machinery and high foot traffic.

Advantages of Using Welded Wire Mesh

10mm steel bar welded wire mesh

One of the primary advantages of using 10mm steel bar welded wire mesh is its high strength-to-weight ratio. The combination of steel's inherent strength and the mesh structure allows for substantial load-bearing capabilities without significantly increasing the weight of the construction elements. This is particularly beneficial in projects where reducing overall weight is a design consideration.

Moreover, the welded connections between the bars contribute to the overall stability of the mesh, preventing the bars from shifting during the concrete pouring process. This feature ensures a uniform distribution of loads, which is critical for the structural integrity of the final product.

Another significant benefit is the ease of installation. Welded wire mesh arrives on-site in pre-fabricated panels, simplifying the placement process and reducing labor costs. Contractors can quickly lay the mesh in the desired location, facilitating a more efficient workflow.

Sustainability Aspects

In an era where sustainability is increasingly prioritized, the use of 10mm steel bar welded wire mesh aligns with eco-friendly construction practices. Steel is 100% recyclable, and using welded wire mesh can contribute to the reduction of waste in construction projects. Additionally, the inherent durability of the mesh minimizes the need for repairs and replacements, further conserving resources over the lifespan of a structure.

Conclusion

In summary, 10mm steel bar welded wire mesh is a fundamental component of modern construction practices. Its versatility, strength, and ease of installation make it an essential choice for builders and engineers looking to enhance the durability and performance of concrete structures. As the construction industry continues to evolve, the adoption of such reliable materials will play a pivotal role in creating safe, sustainable, and resilient environments for future generations. Whether in residential homes or large-scale infrastructure projects, the importance of welded wire mesh cannot be overstated, as it fundamentally supports the backbone of modern construction.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025