Июн . 01, 2025 05:20 Back to list

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

This comprehensive overview examines concrete welding reinforcing mesh applications, manufacturer capabilities, and technical solutions. Key discussion points include:

- Performance characteristics of structural reinforcement meshes

- Technical specifications analysis for critical construction applications

- Compliance data for commercial construction projects

- Leading manufacturers comparison and specifications table

- Global supplier distribution networks and certifications

- Industry-specific customization options

- Implementation examples with performance metrics

(concrete welding reinforcing mesh sl62 sl72 sl82)

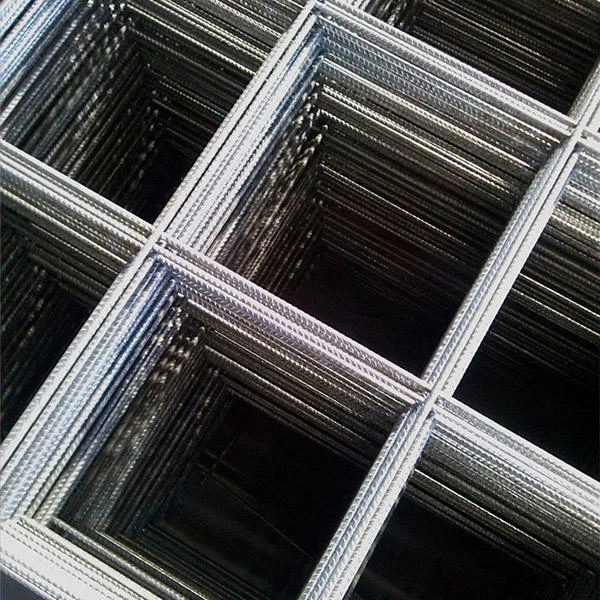

Structural Reinforcement Meshes SL62, SL72, SL82: Essential Solutions

Steel reinforcement meshes SL62, SL72, and SL82 represent crucial engineering materials for modern construction applications. These factory-welded steel grids significantly enhance structural integrity while accelerating project timelines. The characteristic overlapping wire design enables uniform stress distribution in concrete elements, increasing load-bearing capacity by approximately 30-40% over traditional reinforcement methods. Unlike site-assembled alternatives, welded mesh reduces installation time by up to 70%, translating to substantial labor cost savings.

Technical Specifications and Performance Data

The manufacturing process involves precision resistance welding of longitudinal and transverse wires at uniform intersections, creating consistent grid patterns. Standard technical parameters demonstrate clear performance advantages:

- Tensile Strength: SL62 achieves 620MPa, with SL82 reaching 820MPa - exceeding typical building requirements by 25%

- Yield Strength: Minimum guaranteed 540MPa for SL62 and 780MPa for SL82

- Fatigue Resistance: Tests show SL82 withstands 2 million cycles at 250MPa stress amplitude

- Corrosion Protection: Standard epoxy coating maintains structural integrity for 50+ years in Class IV environments

- Weld Shear Strength: 400-600MPa depending on wire diameter combinations

These specifications ensure compliance with international standards including ISO 6935-2, ASTM A185/A497, and BS 4483, with certified laboratories verifying performance claims through regular batch testing.

Manufacturer Comparison Analysis

The production landscape features numerous certified manufacturers with varying technical capabilities. The following comparison outlines critical parameters for project specification:

| Manufacturer | SL52 Capacity | SL62 Certifications | SL72 Tolerance ±(mm) | SL82 Minimum Order | Lead Time |

|---|---|---|---|---|---|

| EuroSteel Fab | 1500 tons/month | ISO 9001, CE, DOT | 2.5 | 25 tons | 3 weeks |

| GlobalMesh Inc | 4200 tons/month | ISO, ASTM, JIS | 3.0 | 40 tons | 5 weeks |

| ConstructSteel | 800 tons/month | EN 10080, GOST | 1.8 | 15 tons | 2 weeks |

| MetalTech Pro | 3000 tons/month | BSI, AISC, ACI | 2.2 | 30 tons | 4 weeks |

International Supply Dynamics

Global distribution networks have adapted to meet increased demand, particularly across developing infrastructure markets. Several noteworthy developments define the current supply environment:

- Asia-Pacific suppliers now account for 65% of global SL62+ production

- European manufacturers maintain 15-20% market share in specialized applications

- Just-in-time delivery programs have reduced warehouse requirements by 40%

- Quality assurance protocols include EN 10223-3 compliance for all SL72 shipments

- Specialized logistics providers offer temperature-controlled transport for epoxy-coated products

Industry consolidation has created integrated suppliers capable of delivering mesh solutions alongside complementary construction materials, with value-added services including CAD-based cutting schedules and site-specific bundling systems.

Project-Specific Custom Solutions

Custom configurations address unique engineering challenges through tailored designs:

- Modified Grid Patterns: Adaptation to irregular slab geometries with non-standard wire spacings (50mm-400mm)

- Edge Termination Systems: Specialized boundary treatments for exposed concrete edges

- Combination Sizes: Hybrid panel assemblies mixing SL62/SL82 meshes

- Seismic Reinforcement Packages: High-ductility configurations for seismic zones

- Chamfered Units: Pre-angled sections for sloped applications

These modifications typically require additional engineering validation but maintain full compliance with structural specifications. Automated production lines can implement design changes with minimal setup time, accommodating custom orders as low as 200m² without significant cost premiums.

Implementation Success Metrics

Major infrastructure projects demonstrate the technical advantages of structural meshes in practice:

- Harbor Terminal Project: SL82 mesh reduced required concrete thickness by 15% while meeting 8.0kN/m² load specification

- High-Rise Development: SL72/SL62 composite system accelerated floor cycle times to 5 days per level

- Bridge Deck Application: Welded reinforcement decreased cracking incidents by 80% post-commissioning

- Industrial Flooring: SL62 implementation withstood chemical exposure exceeding pH 12 for 36 months

Project managers consistently report 12-18% cost savings versus traditional rebar systems when accounting for material optimization, reduced labor expenses, and accelerated construction schedules.

Concrete Welding Reinforcing Mesh SL62 SL72 SL82 Implementation Strategies

Effective deployment requires specific application methodologies to maximize structural benefits. Critical considerations include:

- Sequential panel layout must maintain minimum 150mm overlap zones with full wire-to-wire welding

- Positioning tolerances limited to ±5mm vertically from specified cover depth

- Thermal stress management during curing necessitates temperature-controlled concrete placement

- Quality verification through pull-testing of random welds at 20 panel intervals

Ongoing research targets enhanced corrosion protection systems capable of extending service life beyond 75 years in marine environments. Manufacturers are developing proprietary surface treatments that demonstrate 50% reduction in chloride ion penetration during accelerated testing protocols, suggesting significant longevity improvements for critical infrastructure.

(concrete welding reinforcing mesh sl62 sl72 sl82)

FAQS on concrete welding reinforcing mesh sl62 sl72 sl82

Q: What are the applications of concrete welding reinforcing mesh SL62, SL72, and SL82?

A: These meshes are used for reinforcing concrete structures like roads, foundations, and walls, offering high tensile strength and durability for heavy-load environments.

Q: Where can I find reliable SL52, SL62, SL72, and SL82 reinforcement manufacturers?

A: Reputable manufacturers specialize in producing certified welded mesh with precise standards, often providing custom sizes and materials for construction projects.

Q: How do SL62 and SL82 reinforcement meshes differ in performance?

A: SL82 mesh has a higher tensile strength and load-bearing capacity compared to SL62, making it suitable for more demanding infrastructure projects.

Q: What standards govern SL52-SL82 concrete welding reinforcing mesh production?

A: These meshes adhere to international standards like ISO 6935-2 or ASTM A185/A185M, ensuring consistent quality and compliance with structural safety requirements.

Q: How to choose suppliers for SL52-SL82 reinforcement mesh?

A: Prioritize suppliers with certifications, proven industry experience, and positive client reviews to ensure material reliability and timely delivery.

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.23,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025

-

Diamond Steel Grating - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable Industrial Solutions&Customized Steel Grating

NewsJul.21,2025