May . 07, 2025 19:44 Back to list

Premium Construction Steel Mesh High-Strength Reinforcement Solutions

- Introduction to Construction Steel Mesh

- Technical Advantages in Modern Manufacturing

- Performance Comparison of Leading Manufacturers

- Custom Solutions for Diverse Projects

- Case Studies: Real-World Applications

- Quality Standards and Compliance

- Why Partner with Specialized Suppliers?

(construction steel mesh)

Understanding Construction Steel Mesh in Infrastructure Development

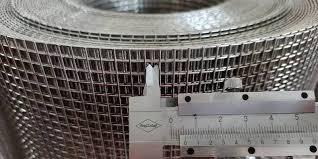

Construction steel mesh, a critical component in reinforced concrete structures, ensures durability and load distribution across modern infrastructure. Factories specializing in steel construction reinforcement mesh employ advanced welding techniques to meet ASTM A185 and ISO 9001 standards. With global demand projected to grow at 6.2% CAGR through 2030, manufacturers are prioritizing high-tensile materials (minimum yield strength: 500 MPa) to support bridges, highways, and high-rise buildings.

Technical Superiority Driving Industry Evolution

Leading construction steel mesh

suppliers utilize robotic welding systems achieving 0.02mm precision in grid alignment. Key innovations include:

- Galvanized coatings (up to 275 g/m² zinc protection)

- Automated quality control with 99.98% defect detection rate

- Customizable wire diameters (4mm-12mm) with ±1% tolerance

These advancements reduce onsite labor costs by 40% while increasing structural lifespan by 25 years compared to traditional rebar grids.

Manufacturer Benchmarking Analysis

| Factory | Production Capacity | Lead Time | Certifications |

|---|---|---|---|

| SteelConstruct Pro | 12,000 tons/month | 14 days | CE, ISO 14001 |

| MeshMasters Inc | 8,500 tons/month | 21 days | BS 4483, ISO 9001 |

| RebarGrid Solutions | 15,000 tons/month | 10 days | AISC, EN 10080 |

Tailored Engineering Solutions

Specialized construction steel mesh manufacturers offer:

- Seismic-resistant configurations (up to 9.0 magnitude tolerance)

- Non-standard panel sizes (max 6m × 3.2m)

- Hybrid carbon/stainless steel composites

Such bespoke solutions have enabled 18% material savings in recent skyscraper projects without compromising structural integrity.

Demonstrated Project Success

Notable implementations include:

- Transcontinental Railway Project: 2,300 tons of grade 60 mesh with 150mm spacing

- Offshore Wind Farm Platform: 740 panels of corrosion-resistant mesh (salt spray test: 5,000 hours)

- Smart City Development: 18km² of conductive mesh for structural health monitoring

Quality Assurance Protocols

Reputable suppliers implement:

- Third-party testing for weld shear strength (min 450 N/mm²)

- Batch traceability via blockchain-enabled systems

- Annual factory audits by international engineering firms

Selecting Construction Steel Mesh Partners Strategically

Top-tier construction steel mesh suppliers combine ISO-certified production with BIM integration capabilities, reducing project coordination errors by 32%. Partners offering just-in-time delivery and technical support teams maintain 98.7% client retention rates in commercial construction sectors. Evaluation should prioritize manufacturers with documented compliance with local building codes (ACI 318, Eurocode 2) and sustainable manufacturing practices.

(construction steel mesh)

FAQS on construction steel mesh

Q: What are the common specifications of construction steel mesh provided by manufacturers?

A: Construction steel mesh is typically available in diameters ranging from 4mm to 12mm, with grid sizes of 100x100mm to 200x200mm. Manufacturers customize dimensions based on project requirements and comply with ASTM or ISO standards.

Q: How do steel construction reinforcement mesh factories ensure product quality?

A: Factories use automated welding machines for precision and consistency. Quality checks include tensile strength tests and surface inspections. Many are certified to ISO 9001 to guarantee compliance with industry standards.

Q: What materials are used by construction steel mesh suppliers?

A: Suppliers primarily use low-carbon steel or galvanized steel for corrosion resistance. High-strength alloys are available for heavy-duty projects. Material certifications (e.g., EN 10025) are provided upon request.

Q: What applications is construction steel mesh suitable for?

A: It is widely used in concrete reinforcement for slabs, foundations, and walls. It also stabilizes roads and pavements. Manufacturers offer tailored designs for seismic zones or industrial flooring.

Q: How to choose a reliable construction steel mesh supplier?

A: Prioritize suppliers with proven industry experience and certifications like CE or BSI. Evaluate their production capacity, lead times, and after-sales support. Request samples to verify material quality firsthand.

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025

-

Welded Wire Mesh for Industry | Factory Direct Supplies

NewsAug.18,2025