Sep . 28, 2024 21:47 Back to list

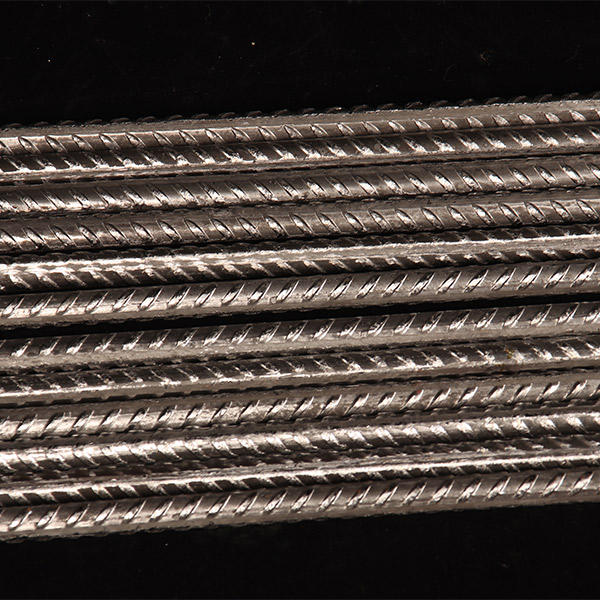

Cold Rolled Rebar Production Facility for Enhanced Strength and Durability

The Evolution and Importance of Cold Rolled Rebar Factories

In recent years, the construction industry has witnessed a significant shift towards the use of advanced materials that enhance structural integrity and durability. Among these innovations, cold rolled rebar has emerged as a pivotal component, revolutionizing the way buildings and infrastructures are constructed. This article delves into the operational dynamics of cold rolled rebar factories, the advantages of cold rolled rebar, and the industry's future prospects.

The Evolution and Importance of Cold Rolled Rebar Factories

The operational efficiency of cold rolled rebar factories is a crucial aspect that determines the quality and cost-effectiveness of the final product. These factories leverage modern technology, utilizing advanced machinery and automation to streamline the production process. High-precision equipment is employed to ensure consistent dimensions and surface finishes, which are critical for meeting industry standards. Automation also minimizes labor costs and reduces the likelihood of human error, leading to higher throughput and improved profitability.

cold rolled rebar factory

In addition to technological advancements, cold rolled rebar factories are increasingly adopting sustainable practices. As environmental concerns escalate, the construction industry is under pressure to reduce its carbon footprint. Cold rolled rebar is often produced from recycled steel, contributing to a circular economy and reducing reliance on virgin materials. Moreover, the efficiency of cold rolling requires less energy compared to traditional processes, further decreasing greenhouse gas emissions associated with production.

The market demand for cold rolled rebar is on the rise, driven by urbanization and the continuous need for infrastructure development. As cities expand and new projects emerge, the construction sector seeks materials that provide reliability and performance. Architects and engineers are increasingly specifying cold rolled rebar in designs, particularly for high-rise buildings, bridges, and other critical infrastructure. The improved properties of cold rolled rebar—such as resistance to seismic activity and corrosion—make it an ideal choice for modern construction challenges.

Looking to the future, cold rolled rebar factories must remain adaptive and innovative. Investing in research and development will be essential for creating new formulations and production techniques that enhance the capabilities of cold rolled rebar. Additionally, as industry standards evolve, factories should focus on achieving certifications that ensure compliance with international safety and quality regulations.

In conclusion, cold rolled rebar factories are at the forefront of a transformative movement within the construction sector. By leveraging technological advancements and sustainable practices, these factories not only produce superior materials but also contribute to a more resilient built environment. As the demand for durable and efficient construction materials continues to grow, cold rolled rebar is likely to play an increasingly significant role in shaping the future of infrastructure development.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025