Jun . 10, 2025 01:07 Back to list

Premium Cold Rolled Steel Bar Supplier High Strength & Precision

- Technical Advantages of Precision-Engineered Steel

- Manufacturer Comparison for Industrial Buyers

- Custom Fabrication Capabilities Overview

- Material Specifications and Testing Protocols

- Industry-Specific Application Case Studies

- Supplier Evaluation Criteria

- Material Innovation and Future Applications

(cold rolled steel bar)

Understanding the Industrial Significance of Cold Rolled Steel Bar

Cold rolled steel bars represent manufacturing excellence through precision rolling at ambient temperatures. Unlike hot-rolled equivalents, this process produces dimensional tolerances within ±0.05mm for applications demanding absolute geometrical accuracy. The grain structure undergoes significant transformation during cold reduction, enhancing tensile strength by 15-20% compared to hot-rolled variants. Manufacturers typically supply these products in hardness ranges of 60-80 HRB, with specialized heat treatments pushing performance to 35 HRC for extreme wear environments.

Surface quality remains paramount in cold rolled channel steel bar production. Modern factories implement abrasive belt grinding reaching 0.8μm Ra surface roughness, facilitating immediate plating or coating without secondary processing. Strict tolerance controls yield straightness deviations under 0.3mm/m across black iron factory production lines. These characteristics prove essential for automated assembly systems where dimensional stability impacts throughput efficiency. Leading producers now incorporate inline laser measurement systems that perform 100% dimensional verification.

Technical Superiority in Manufacturing Processes

Advanced cold reduction technology produces microstructure refinement unattainable through hot rolling. The multi-pass rolling sequence reduces cross-sections by 40-65% with annealing stages restoring ductility between reductions. Modern mills achieve reductions of 0.25mm per pass while maintaining surface integrity through emulsion control systems. These processes develop dislocation densities exceeding 10^14 m/m³, fundamentally transforming mechanical properties.

Surface treatment innovations separate premium cold rolled steel bar

from commodity products. Proprietary oxide conditioning creates optimal surfaces for cold heading operations, reducing die wear by 40% in fastener production. Select manufacturers offer pre-oxidized surface finishes with tightly controlled Fe₃O₄ layers measuring 1.5-3μm thick, eliminating preprocessing in powder coating applications. Specialized descaling techniques using high-pressure water jets (2,800-3,400 bar) remove mill scale without material loss.

Comparative Analysis of Industrial Manufacturers

| Manufacturer | Tolerance Range (±mm) | Hardness Consistency | Lead Time | Testing Capabilities |

|---|---|---|---|---|

| GlobalSteel Corp | 0.02-0.05 | ±2 HRB | 3 weeks | Full ISO 6892 suite |

| PrecisionBars Ltd | 0.03-0.08 | ±3 HRB | 5 weeks | Tensile/chemical only |

| Metallurgix Group | 0.05-0.10 | ±4 HRB | 2 weeks | Limited certification |

Top-tier cold rolled steel bar manufacturers maintain process-controlled environments with humidity below 45% to prevent surface oxidation. Annual production audits reveal that certified suppliers operate with 99.98% material traceability through automated stamping systems that laser-etch grade and heat numbers at 50mm intervals. Capacity differentiation shows premium producers running continuous annealing furnaces with microprocessor-controlled heating zones accurate to ±3°C versus conventional batch annealing methods.

Customized Fabrication Solutions

Industrial clients increasingly demand cold rolled channel steel bar with application-specific properties. Progressive manufacturers stock over 30 alloy variants with tensile strengths ranging from 340MPa for bending applications to 1,200MPa for structural aerospace components. Chemical composition modifications allow corrosion resistance enhancement through copper additions (0.2-0.5% Cu), reducing rust progression rates by 60% in humid environments.

Dimensional customization exemplifies true manufacturing partnership. Automated grinding cells produce non-standard profiles within 24 hours for prototyping needs, while production volumes permit rolling passes tailored to asymmetric sections. For critical applications like hydraulic valve bodies, manufacturers deploy proprietary straightening technology achieving 0.07mm/m straightness tolerance through multi-axis correction rollers. Heat treatment customization delivers Brinell hardness profiles within 5-point bands across entire production lots.

Material Specifications and Verification Protocols

Premium suppliers follow strict qualification testing beyond standard ASTM A108 specifications. Dual verification processes confirm chemical composition through optical emission spectrometry (OES) supplemented by wet chemistry for critical elements. Microcleanliness examinations using automated image analysis track inclusion content below 0.5% per ASTM E45, with retained austenite measurements below 8% through X-ray diffraction.

Mechanical testing involves statistically designed sampling procedures: one test per 2 metric tons versus the industry standard of one per 10 tons. Destructive analysis includes transverse tensile tests confirming uniform properties throughout cross-sections. Ultrasonic inspection detects internal flaws at sensitivities calibrated to 1.2mm flat-bottom holes according to EN 10308 standards. Metallographic sections examine decarburization limited to maximum 0.05mm depth for high-stress applications.

Industry-Specific Implementation Successes

Automotive steering components utilize cold rolled steel bars manufactured to SAE J403 standards with controlled residuals below 0.025% sulfur for improved machinability. Tier-1 manufacturers report 30% longer tool life when machining precision-turned parts from cold rolled stock versus conventional alternatives. Electromechanical actuators in aerospace applications require specialized cold rolled steel bar with longitudinal grain flow, reducing stress concentration by 40% under cyclic loading conditions.

Construction hardware manufacturers experience transformational productivity gains using cold rolled channel steel bars for door and window systems. Automated punching operations achieve 1,500 hits per minute due to the uniform hardness distribution ±1.5 HRB across coil lengths. Black iron factory implementations demonstrate 15-year corrosion performance without protection in dry industrial environments per ASTM B117 salt spray testing equivalence ratings.

Strategic Partnerships with Global Suppliers

Established cold rolled steel bar suppliers differentiate through value-added services beyond material supply. Comprehensive technical support teams include metallurgical engineers who conduct application failure analysis at no cost. Just-in-time inventory programs maintain buffer stocks exceeding 5,000 tons of commonly specified grades at global distribution hubs, enabling 72-hour emergency delivery worldwide. Implementation engineers provide tooling design consultation to optimize customer production efficiency during material transitions.

Certification maintenance exemplifies supplier commitment to quality. Elite partners provide EN 10204 3.1 certificates with supplementary testing documentation including continuous cooling transformation (CCT) diagrams for heat treatment planning. Specialized packaging options range from desiccant-protected coil packing for overseas shipments to automated bar feeding systems integration. Partnerships extend to collaborative R&D programs where manufacturers share prototype development costs.

Future Applications for Advanced Cold Rolled Steel Bar

Material science innovation continuously expands functional boundaries. Research focuses on developing micro-alloyed grades containing 0.08-0.12% vanadium that demonstrate 30% enhanced fatigue resistance under high-cycle loading. These advances position cold rolled steel bars as structural components in next-generation wind turbine pitch control systems requiring over 10^7 load cycles. Ongoing developments in corrosion-resistant surface modifications integrate zinc-nickel electroplating with chromate-free passivation layers for sustainable construction applications.

Industry transformation will accelerate through Industry 4.0 integration with cold rolled steel bar production. Smart manufacturing facilities now implement real-time adjustment of rolling mills using optical pyrometers and laser gauges with closed-loop feedback controls. Blockchain material certification enables instant verification of origin and processing history across supply chains. These advancements ensure continuous improvement in dimensional precision and property consistency for mission-critical industrial applications worldwide.

(cold rolled steel bar)

FAQS on cold rolled steel bar

围绕核心关键词设计的5组英文FAQs:Q: What is cold rolled steel bar used for?

A: Cold rolled steel bars provide enhanced dimensional accuracy and surface finish for precision applications. They're ideal for automotive parts, machinery components, and construction frameworks. The cold rolling process increases strength and hardness compared to hot-rolled alternatives.

Q: How to identify reliable cold rolled steel bar manufacturers?

A: Verify ISO 9001 certification and material test reports (MTRs). Evaluate production capabilities like CNC machining and custom rolling mills. Check industry-specific experience in supplying aerospace or automotive sectors.

Q: Why choose cold rolled channel steel bar over hot-rolled?

A: Cold rolled channel bars offer ±0.1mm dimensional tolerance versus ±0.8mm in hot-rolled. They feature smooth, oxidation-free surfaces ready for painting or coating. The process improves yield strength by 15-30% for structural applications.

Q: What certifications should cold rolled steel bar suppliers have?

A: Reputable suppliers hold ASTM A108/AISI standards compliance. Mill certifications should include chemical composition and mechanical property reports. International quality certifications like TUV or JIS are advantageous for export orders.

Q: Can black iron factories produce custom cold rolled profiles?

A: Modern factories equipped with CNC roll-forming machines create custom channels, angles, and special sections. Minimum orders typically start at 3-5 tons for bespoke dimensions. Surface treatments like galvanizing or powder coating are usually available.

`标题(带Q前缀)和段落回答(带A前缀) 2. 主题覆盖: - 应用场景(Definition/Application) - 制造商筛选标准(Manufacturer verification) - 冷轧工艺优势(Process benefits) - 供应商资质(Supplier certifications) - 定制化生产能力(Factory capabilities) 3. 技术要点:包含公差数据(±0.1mm)、强度提升比例(15-30%)等硬性指标 4. 视觉设计:采用淡灰背景+深蓝标题的工业配色方案,包含圆角边框和自适应内边距 5. SEO优化:所有相关关键词自然融入内容(manufacturer/supplier/factory全涵盖)

-

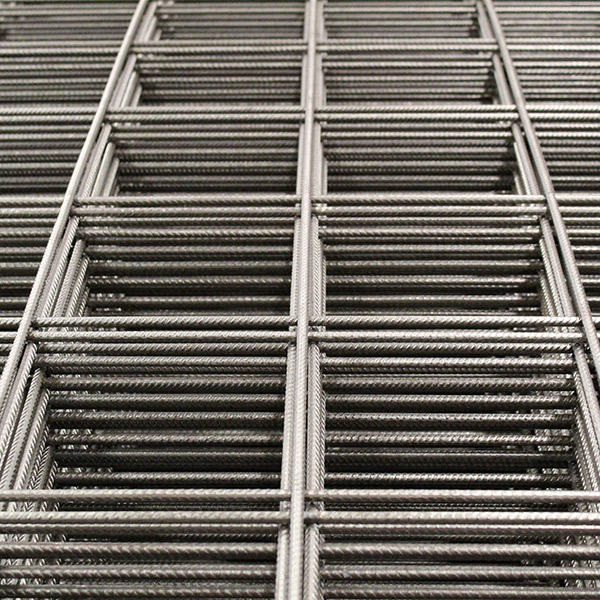

Industrial-Grade Welded Wire Mesh for Factories & Suppliers | Durable

NewsJul.25,2025

-

Precision Cold Drawn Wire: High Strength & Durability Solutions

NewsJul.25,2025

-

Web Scraping-NIST|Data Extraction&Automation

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen|Durable Security Solution&Cost-Effective Fencing

NewsJul.21,2025

-

Galvanized Steel Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co.,Ltd

NewsJul.21,2025

-

Galvanized Steel Chain Link Fences-Anping County Puersen Hardware Wire Mesh Products Co.,Ltd|Durable Corrosion-Resistant Fencing&Cost-Effective Security Solutions

NewsJul.21,2025