12月 . 19, 2024 20:12 Back to list

6mm cold drawn wire factory

The Evolution and Significance of 6mm Cold Drawn Wire Factories

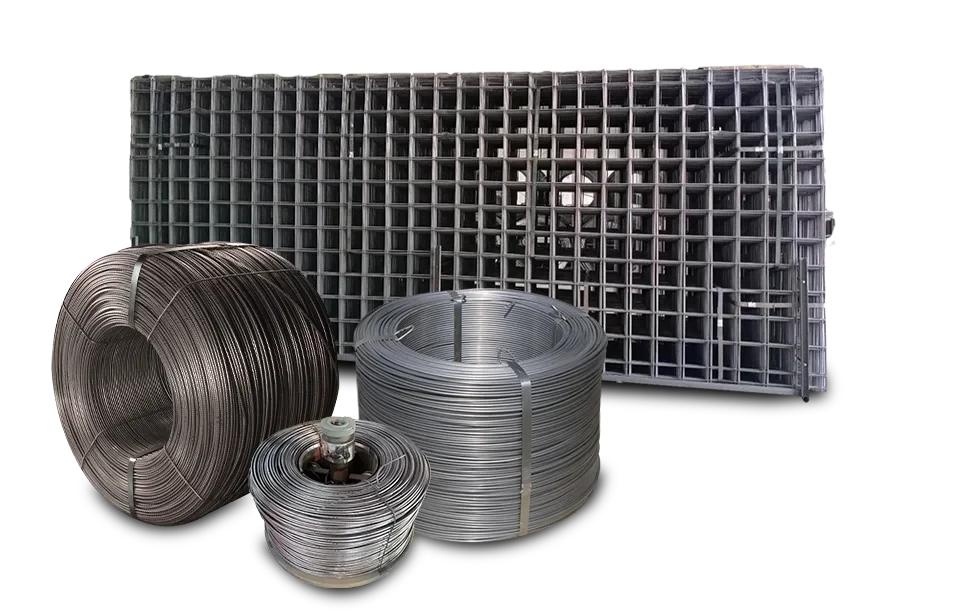

Cold drawn wire has become an essential component in various industries, thanks to its unique properties that serve numerous applications. Among the different sizes of cold drawn wire, the 6mm diameter cold drawn wire holds particular significance due to its versatility and strength. As the demand for this product increases, the factories dedicated to producing 6mm cold drawn wire have evolved in both technology and methodologies, leading to improved efficiency, quality, and sustainability.

Understanding Cold Drawing

Cold drawing is a metalworking process that involves pulling a metal wire through a die to reduce its diameter and improve its mechanical properties, such as tensile strength and hardness. The process is conducted at room temperature, which helps maintain the material's structural integrity. Cold drawn wire is often preferred over hot rolled wire for applications requiring precise dimensions and better surface finish.

Applications of 6mm Cold Drawn Wire

The applications of 6mm cold drawn wire are extensive, affecting various sectors such as construction, automotive, and manufacturing. In construction, this wire is commonly used in reinforcement applications, including concrete reinforcement bars. The high tensile strength of cold drawn wire makes it suitable for holding together structural elements, ensuring the stability and longevity of buildings and infrastructures.

In the automotive industry, 6mm cold drawn wire serves as an essential component in spring manufacturing, providing the necessary resilience and flexibility. Additionally, it finds utility in producing various automotive parts, contributing to the overall safety and efficiency of vehicles.

Manufacturers also rely on 6mm cold drawn wire to produce items ranging from tools to furniture components

. Its adaptability makes it a popular choice in crafting high-quality products that demand both strength and precision.The Manufacturing Process

The manufacturing of 6mm cold drawn wire begins with the selection of high-grade steel, which is then processed through several stages to achieve the desired dimensions. Initially, the steel wire undergoes cleaning and annealing to enhance its ductility before being drawn through a series of progressively smaller dies. This process reduces the diameter and aligns the crystalline structure of the steel, which enhances its mechanical properties.

6mm cold drawn wire factory

Quality control is paramount throughout the production process. Factories implement rigorous testing methods to ensure that the wire meets industry standards and specifications. These tests can include tensile strength measurements, surface quality inspections, and dimensional checks.

Technological Advancements in Cold Drawn Wire Production

With the rapid advancement of technology in manufacturing, 6mm cold drawn wire factories have adopted modern machinery and automated processes to increase production efficiency. Automated drawing machines allow for precise control over the drawing process, reducing material waste and enhancing dimensional accuracy. Furthermore, advancements in computer-aided design (CAD) and computer numerical control (CNC) systems enable manufacturers to optimize production processes and respond rapidly to changing market demands.

Moreover, innovative practices such as lean manufacturing and sustainable production techniques are being integrated into factory operations. By minimizing waste and optimizing resource usage, factories not only enhance profitability but also contribute to environmental sustainability—a growing concern in today’s industrial landscape.

Challenges and Opportunities

Despite the advancements, 6mm cold drawn wire factories face several challenges. The fluctuating prices of raw materials can significantly impact production costs, requiring manufacturers to implement effective supply chain strategies. Additionally, increasing competition from international markets necessitates a focus on quality and innovation to maintain a competitive edge.

However, these challenges also present opportunities. The growing demand for high-strength materials in industries such as renewable energy and aerospace positions 6mm cold drawn wire as a fundamental product for future innovations. Factories that embrace technology, sustainability, and quality will likely thrive in this evolving landscape.

Conclusion

The 6mm cold drawn wire factory represents a vital facet of modern manufacturing, contributing significantly to various industries worldwide. As technology continues to advance and market demands evolve, these factories must remain agile, embracing innovations that enhance quality and efficiency. With a commitment to excellence and sustainability, the future of cold drawn wire production looks promising, ensuring its critical role in the construction of a robust industrial foundation.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025