Set . 25, 2024 23:57 Back to list

8 gauge galvanized wire manufacturers

Understanding the Market for 8% Gauge Galvanized Wire Manufacturers

In the industrial landscape, galvanized wire has become an essential material across various applications due to its durability and resistance to corrosion. Among the different sizes and gauges available, 8% gauge galvanized wire stands out for its unique properties and versatility. Manufacturers specializing in this particular gauge are pivotal in supplying industries that require strong, reliable wire for construction, fencing, electrical applications, and more.

What is 8% Gauge Galvanized Wire?

Galvanized wire is steel wire that has been coated with zinc to protect it from rust and corrosion. The gauge refers to the wire's diameter, with lower numbers indicating thicker wires. An 8% gauge wire generally measures approximately 0.128 inches or 3.2 millimeters in diameter. This thickness makes it suitable for heavy-duty applications, providing an excellent balance between strength and flexibility.

Applications of 8% Gauge Galvanized Wire

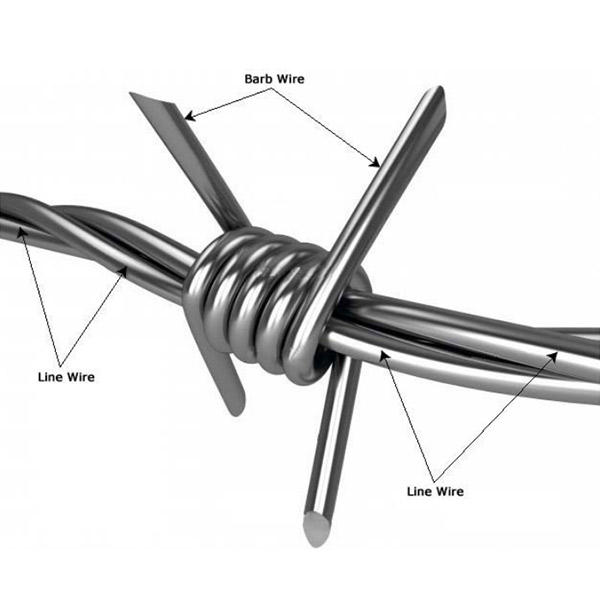

1. Fencing One of the primary uses of 8% gauge galvanized wire is in fencing applications. It is commonly used for livestock fencing, agricultural fencing, and security fences. The wire's strength ensures that it can withstand tension and pressure, effectively keeping animals in and intruders out.

2. Construction In the construction industry, this type of wire is utilized for various purposes, including reinforcement in concrete and as part of mesh systems. Its corrosion resistance is particularly beneficial in outdoor or high-moisture environments.

3. Electrical Applications 8% gauge galvanized wire is also utilized for grounding and bonding in electrical installations. The zinc coating provides a high level of conductivity while preventing corrosion, making it an ideal choice for outdoor electrical applications.

The Manufacturing Process

8 gauge galvanized wire manufacturers

The manufacturing of galvanized wire begins with drawing steel wire to the desired gauge, followed by a galvanization process where the wire is coated in molten zinc. This process can be achieved through hot-dip galvanization or electro-galvanization, each with its unique benefits. Hot-dip galvanization typically provides a thicker coating, making it more suitable for outdoor applications, while electro-galvanization offers a smoother finish for applications where appearance is critical.

Selecting the Right Manufacturer

When choosing a manufacturer for 8% gauge galvanized wire, several factors should be taken into consideration

1. Quality Standards Ensure that the manufacturer adheres to international quality standards, such as ISO 9001. Quality assurance is vital for ensuring the longevity and reliability of the wire.

2. Customization Options Some manufacturers offer custom wire solutions tailored to specific applications. This could include adjusting the zinc coating thickness or providing specific lengths based on client needs.

3. Brand Reputation Researching a manufacturer’s reputation in the industry can provide insight into their reliability and the quality of their products. Client testimonials and case studies can be indicative of a manufacturer’s capabilities.

4. Cost-Effectiveness While price should not be the sole determinant, it is essential to weigh the cost against the quality of the product. Finding a manufacturer that provides competitive pricing without compromising on quality is key.

5. Customer Service Good customer service can significantly enhance the buying experience. A manufacturer that is responsive and supportive can provide valuable assistance during the selection and purchase processes.

Conclusion

The demand for 8% gauge galvanized wire continues to grow across various sectors due to its strength and versatility. Manufacturers play a crucial role in meeting this demand by providing high-quality wire that meets industry standards. By understanding the applications, manufacturing processes, and criteria for selecting suitable manufacturers, businesses can make informed decisions that enhance their operations and project outcomes. Whether for industrial use or DIY projects, the right galvanized wire can make all the difference in achieving successful results.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025