Des . 27, 2024 00:27 Back to list

Benefits and Applications of Perforated Metal Sheets in Modern Industries

Understanding Perforated Metal Sheets Applications and Benefits

Perforated metal sheets are versatile materials widely used across various industries, renowned for their unique combination of functionality and aesthetic appeal. Made from a range of metals, including stainless steel, aluminum, and mild steel, these sheets are characterized by a series of holes that are punched or drilled into them. Depending on the manufacturing process and specific requirements, the size, shape, and spacing of the holes can vary significantly, allowing for a broad spectrum of applications.

Manufacturing Process

The production of perforated metal sheets involves precision engineering. Typically, sheets of metal are fed into a machine equipped with a die and punch, which create holes in predetermined patterns. Advanced technology allows for a high degree of customization, meaning that businesses can order perforated sheets to meet their exact specifications, whether for decorative, functional, or structural purposes.

Aesthetic Appeal

One of the primary reasons for the popularity of perforated metal sheets is their aesthetic value. When used in architectural designs, they can add a modern, stylish touch. The interplay of light and shadow through the holes creates dynamic visual effects, making them a favored choice for facades, screens, and partitions. Designers often employ these sheets not only for their practical benefits but also to enhance the overall aesthetic charm of buildings and interiors.

Functional Benefits

Beyond aesthetics, perforated metal sheets offer numerous functional advantages. Their lightweight yet durable nature makes them suitable for various applications, including

1. Ventilation and Filtration The presence of holes allows for airflow, which is critical in environments that require ventilation. Perforated sheets can be used in air conditioning systems, exhaust hoods, and as filters in industrial processes.

perforated metal sheet

2. Sound Absorption Perforated metal sheets can effectively dampen sound, making them ideal for use in music venues, offices, and other spaces where noise control is essential. The unique design helps to break up sound waves, reducing echoes and noise levels.

3. Security In the realm of security, perforated metal can serve as a protective barrier while still allowing visibility. This feature makes them suitable for use in guardrails, gates, and fencing without compromising on safety.

4. Shelving and Storage They are often used to create durable shelving units in warehouses and storage facilities. The perforations allow for efficient drainage and air circulation, reducing the risk of moisture damage to stored goods.

5. Light Diffusion In lighting applications, perforated panels can diffuse light effectively, creating softer illumination. This is particularly beneficial in settings where harsh lighting needs to be mitigated.

Environmental Considerations

In the context of sustainability, perforated metal sheets can also play a role in eco-friendly design. Their ability to allow natural light and air to flow through reduces the need for artificial lighting and air conditioning, contributing to lower energy consumption. Moreover, metals like stainless steel are recyclable, helping to minimize waste and promote a circular economy.

Conclusion

Perforated metal sheets embody a perfect blend of functionality and design. Their wide-ranging applications across various sectors—from construction and manufacturing to art and design—demonstrate their versatility. With continued advancements in manufacturing technology, the potential uses for these sheets are likely to expand even further. Whether for practical solutions or enhancing aesthetic appeal, perforated metal sheets offer an innovative way to meet diverse needs efficiently and sustainably. As industries continue to adopt more eco-friendly practices, the use of perforated sheets will undoubtedly play a pivotal role in shaping the future of material design and application.

-

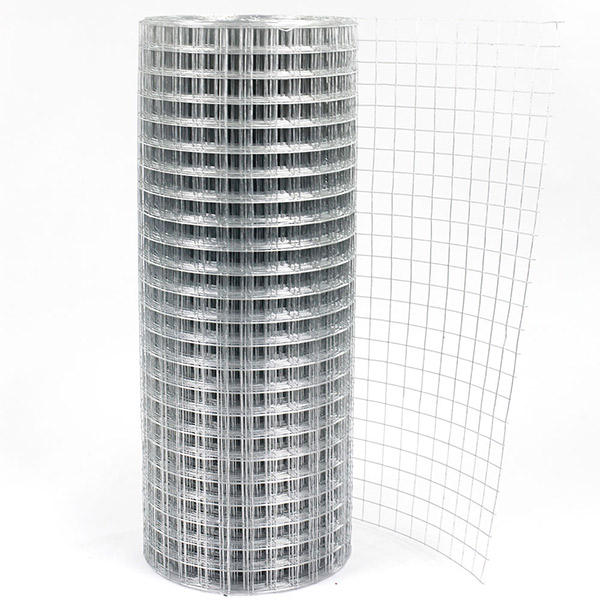

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025