Սպտ . 01, 2025 10:40 Back to list

welded wire mesh - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Construction, Industrial Applications

Welded wire mesh has become a cornerstone material in construction, industrial manufacturing, and infrastructure development. Its combination of durability, cost-effectiveness, and adaptability makes it a preferred choice across multiple sectors. This article provides an in-depth analysis of welded wire mesh, covering its technical specifications, key applications, manufacturing processes, and the company behind this innovation—Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

Overview of Welded Wire Mesh

Welded wire mesh is a structural material composed of low carbon steel wire or stainless steel wire, welded together at intersecting points and subsequently treated to enhance corrosion resistance. This material is widely utilized in concrete reinforcement, fencing, architectural design, agricultural systems, and industrial machinery. Its versatility stems from its ability to be customized in terms of mesh size, wire diameter, and surface treatment.

The product is available in various forms, including hot-dip galvanized, electric-galvanized, and PVC-coated versions, each tailored for specific environmental and functional requirements. These treatments not only improve the material's longevity but also expand its applicability in harsh conditions such as high humidity or chemical exposure.

Technical Specifications and Customization Options

The technical parameters of welded wire mesh are defined by its mesh opening size, wire diameter, and surface treatment. Below is a detailed specification table for standard welded wire mesh:

| (Standard Mesh) IN 30m/roll, width 0.5-2.5m | ||

| Opening | In metric unit (mm) | Wire Diameter (BWG) |

| 1/4" x 1/4" | 6.4mm x 6.4mm | 22, 23, 24 |

| 3/8" x 3/8" | 10.6mm x 10.6mm | 19, 20, 21, 22 |

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16, 17, 18, 19, 20, 21, 22, 23 |

| 5/8" x 5/8" | 16mm x 16mm | 18, 19, 20, 21 |

| 3/4" x 3/4" | 19.1mm x 19.1mm | 16, 17, 18, 19, 20, 21 |

| 1" x 1/2" | 25.4mm x 12.7mm | 16, 17, 18, 19, 20, 21 |

| 1-1/2" x 1-1/2" | 38mm x 38mm | 14, 15, 16, 17, 18, 19 |

| 1" x 2" | 25.4mm x 50.8mm | 14, 15, 16 |

| 2" x 2" | 50.8mm x 50.8mm | 21, 22, 23, 24 |

For galvanized welded wire mesh fencing, the specifications are as follows:

| Galvanized Welded Wire Mesh Fence IN 30m/roll, width 0.5-2.5m | ||

| Opening | In metric unit (mm) | Wire Diameter (BWG) |

| 2" x 3" | 50mm x 75mm | 2.0mm, 2.5mm, 1.65mm |

| 3" x 3" | 75mm x 75mm | 2.67mm, 2.41mm, 2.11mm, 1.83mm, 1.65mm, 4.0mm |

| 2" x 4" | 50mm x 100mm | 2.11mm, 2.5mm, 3.0mm, 4.0mm |

| 4" x 4" | 100mm x 100mm | 2.0mm, 2.5mm, 3.0mm, 4.0mm |

For PVC-coated welded wire mesh, the specifications include:

| PVC Coated Welded Wire Mesh IN 30m/roll, width 0.5-2.5m | ||

| Opening | In metric unit (mm) | Wire Diameter (BWG) |

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16, 17, 18, 19, 20, 21 |

| 3/4" x 3/4" | 19mm x 19mm | 16, 17, 18, 19, 20, 21 |

| 1" x 1" | 25.4mm x 25.4mm | 15, 16, 17, 18, 19, 20 |

These specifications highlight the modularity and customizability of welded wire mesh, allowing it to meet the unique demands of various industries.

Key Applications of Welded Wire Mesh

The versatility of welded wire mesh is evident in its wide range of applications. Below are some of the most common uses:

- Fences and gates: Ideal for residential, commercial, and industrial properties, offering both security and aesthetic appeal.

- Architectural uses: Utilized in building facades, infill panels, and green building designs to enhance LEED certification compliance.

- Animal control: Used in livestock fencing and stray animal containment due to its strength and durability.

- Machine guarding: Provides safety barriers for industrial machinery, ensuring operator protection.

- Shelving and partitions: Offers stability and visibility for storage solutions in warehouses and retail spaces.

- Agriculture: Employed in corn cribs, livestock shade panels, and temporary holding pens.

- Construction: Essential for concrete reinforcement, wall support, and flooring systems.

For instance, the PVC-coated version is particularly suited for outdoor applications where corrosion resistance is critical. Its smooth surface and color options make it a popular choice for architectural grilles and decorative panels.

Manufacturing Processes and Surface Treatments

The production of welded wire mesh involves several critical steps to ensure quality and performance:

- Wire selection: High-quality low carbon steel or stainless steel wires are chosen for their tensile strength and corrosion resistance.

- Welding: Wires are automatically welded at intersecting points using high-frequency welding techniques to create a rigid structure.

- Surface treatment: Post-welding, the mesh undergoes treatments such as hot-dip galvanization, electric galvanization, or PVC coating to enhance longevity and environmental adaptability.

Each surface treatment offers distinct advantages:

- Hot-dip galvanization: Provides a thick zinc coating for extreme corrosion resistance in marine or industrial environments

- Electric galvanization: Offers a smooth, uniform coating for aesthetic applications and moderate corrosion protection

- PVC coating: Adds UV resistance, color flexibility, and impact protection, making it ideal for outdoor and decorative uses

These processes ensure that the final product meets industry standards and customer requirements

Company Background: Anping County Puersen Hardware Wire Mesh Products Co., Ltd

As a leading manufacturer in the wire mesh industry, Anping County Puersen Hardware Wire Mesh Products Co., Ltd has established itself as a trusted supplier of high-quality welded wire mesh. Located in Anping County, a renowned hub for wire mesh production in China, the company leverages advanced manufacturing technologies and strict quality control to deliver durable and reliable products

With decades of experience, the company specializes in customized solutions for construction, agriculture, industrial, and architectural applications

For more information about the company's products and services, visit their official website.

Industry Relevance and Standards

The use of welded wire mesh aligns with industry standards for safety, durability, and sustainability. According to the National Institute of Standards and Technology (NIST), materials used in construction must meet rigorous performance criteria to ensure structural integrity and long-term reliability

Welded wire mesh, particularly galvanized and PVC-coated variants, is recognized for its compliance with NIST standards in terms of corrosion resistance and mechanical strength

Conclusion

Welded wire mesh is a versatile and indispensable material in modern construction and industrial applications. Its customizable specifications, robust surface treatments, and wide-ranging applications make it a preferred choice for engineers, architects, and manufacturers. With Anping County Puersen Hardware Wire Mesh Products Co., Ltd as a reliable supplier, users can access high-quality solutions tailored to their specific needs.

For further details about the product, visit the product page or explore the company website.

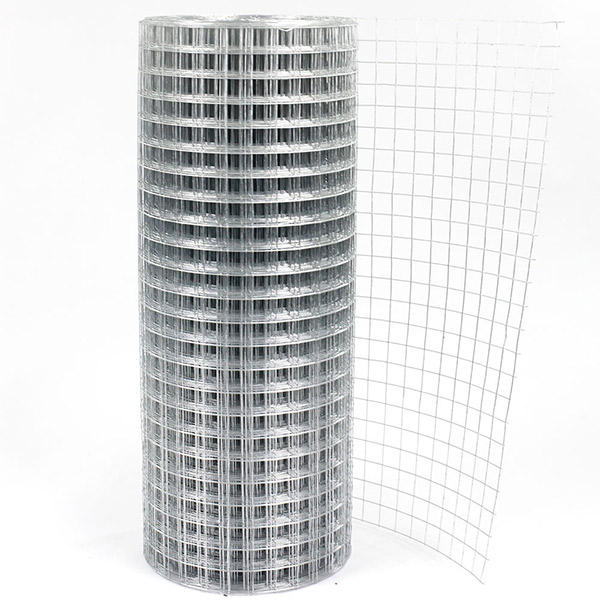

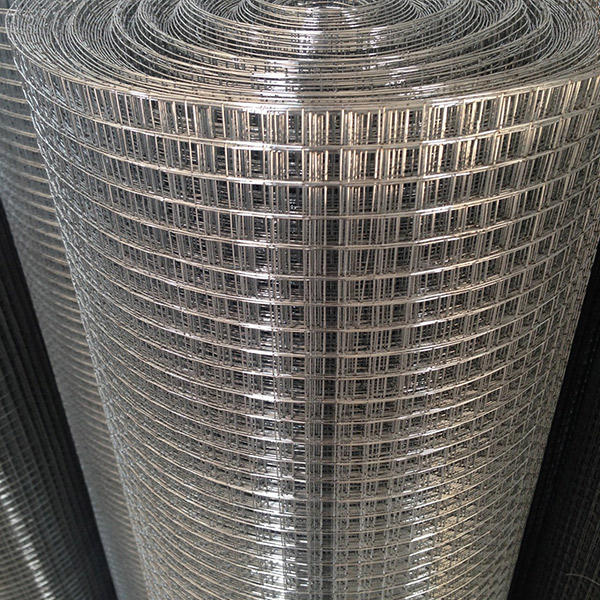

Product Images

References

National Institute of Standards and Technology (NIST) – Industry standards for construction materials.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory | Structural Strength & Corrosion Resistance

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Corrosion-Resistant Solutions

NewsSep.01,2025

-

Welded Wire Mesh for Industrial - Anping Puersen | Durability, Corrosion Resistance

NewsSep.01,2025

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsSep.01,2025

-

Welded Wire Mesh - Anping Puersen|Durability&Corrosion Resistance

NewsSep.01,2025