Փտր . 18, 2025 03:12 Back to list

Cold Drawn Wire

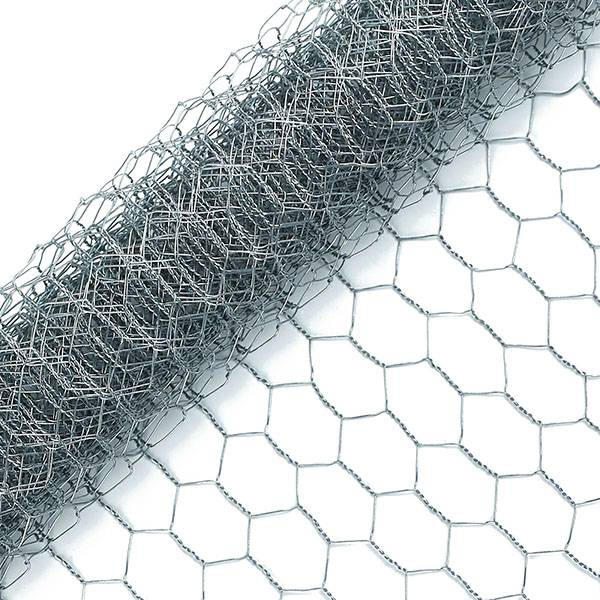

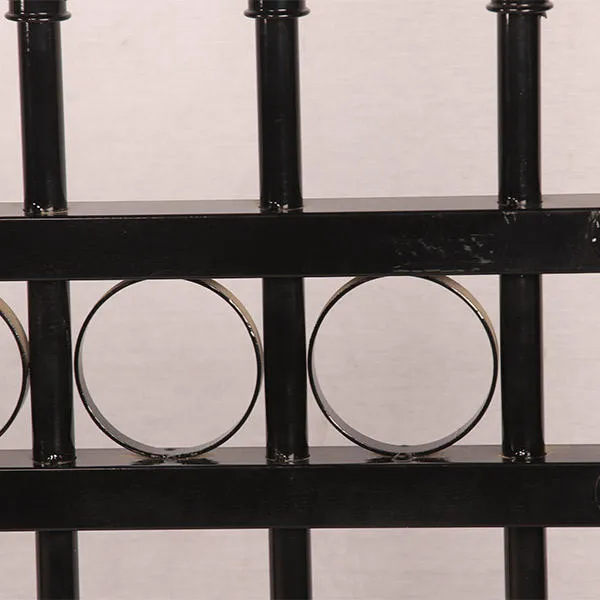

OEM wire panels and welded wire mesh have become an integral part of various industrial applications due to their efficiency and versatility. These products serve as fundamental building blocks for creating sturdy and durable structures, making them an essential procurement for industries ranging from construction to agriculture. Throughout my extensive experience in engineering and project management, I've observed the transformative impact of these materials on industrial efficiencies.

Authoritativeness in this domain is established through rigorous testing and compliance with industry protocols. Each batch of wire mesh or panel undergoes extensive quality assurance checks to confirm its durability, tensile strength, and resistance to environmental factors. My engagement with regulatory bodies enables me to stay at the forefront of compliance standards, which I then translate into actionable policies for businesses eager to maintain their competitive edge. Trustworthiness is built on consistent performance and transparent communication. By fostering partnerships with reputable suppliers, I ensure that products are delivered on time and to specification. My commitment to quality and transparency has established a track record of successful deployments, reinforcing trust with clients who seek reliability in their industrial supplies. In conclusion, OEM wire panels and welded wire mesh are invaluable assets across numerous sectors. Through my experience and expertise, I've witnessed how tailored solutions and adherence to high standards can significantly amplify industrial performance. By leveraging authoritative insights and nurturing trustworthy partnerships, businesses can harness the full potential of these materials, driving both innovation and growth. Whether it’s a large-scale construction project or a small-scale agricultural setup, the strategic use of these wire products can pave the way for remarkable advancements and sustained success.

Authoritativeness in this domain is established through rigorous testing and compliance with industry protocols. Each batch of wire mesh or panel undergoes extensive quality assurance checks to confirm its durability, tensile strength, and resistance to environmental factors. My engagement with regulatory bodies enables me to stay at the forefront of compliance standards, which I then translate into actionable policies for businesses eager to maintain their competitive edge. Trustworthiness is built on consistent performance and transparent communication. By fostering partnerships with reputable suppliers, I ensure that products are delivered on time and to specification. My commitment to quality and transparency has established a track record of successful deployments, reinforcing trust with clients who seek reliability in their industrial supplies. In conclusion, OEM wire panels and welded wire mesh are invaluable assets across numerous sectors. Through my experience and expertise, I've witnessed how tailored solutions and adherence to high standards can significantly amplify industrial performance. By leveraging authoritative insights and nurturing trustworthy partnerships, businesses can harness the full potential of these materials, driving both innovation and growth. Whether it’s a large-scale construction project or a small-scale agricultural setup, the strategic use of these wire products can pave the way for remarkable advancements and sustained success.

Next:

Latest news

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Security, Versatile Application

NewsAug.10,2025