Դկտ . 21, 2024 18:49 Back to list

low carbon cold drawn steel wire 3mm factories

The Rise of Low Carbon Cold Drawn Steel Wire Factories

In the contemporary industrial landscape, the push towards sustainability has led to significant changes in manufacturing processes. One area that has seen a marked transformation is the production of cold drawn steel wire, particularly low carbon variants. Low carbon cold drawn steel wire, typically measuring 3mm in diameter, has emerged as a crucial material in various applications, from construction to automotive industries. This article delves into the significance of low carbon cold drawn steel wire factories and their impact on modern manufacturing.

Understanding Low Carbon Cold Drawn Steel Wire

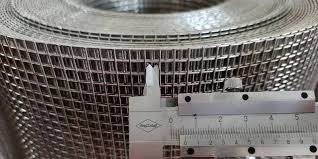

Low carbon steel wire is characterized by its relatively low carbon content (generally below 0.25%), which enhances its ductility and malleability. These properties make it ideal for production processes that require complex shapes and designs. Cold drawing, the process of pulling the wire through a die to reduce its diameter while increasing its tensile strength and surface finish, further enriches these qualities. The end product, particularly 3mm wire, is known for its strength, flexibility, and corrosion resistance, making it a popular choice in numerous sectors.

Environmental Benefits

One of the primary advantages of using low carbon steel is its reduced environmental impact compared to high carbon alternatives. The production of low carbon steel typically consumes less energy and emits fewer greenhouse gases. Factories focusing on low carbon steel wire manufacturing are often equipped with advanced technologies that minimize waste and encourage recycling of materials. For example, the use of electric arc furnaces, which can incorporate a significant proportion of recycled steel scrap, demonstrates a commitment to resource efficiency and sustainability.

Technological Innovations

low carbon cold drawn steel wire 3mm factories

The modern low carbon cold drawn steel wire factories have embraced technological innovations to enhance productivity and product quality. Automation in production lines has streamlined operations, reducing labor costs and minimizing human error. Additionally, sophisticated monitoring systems allow factories to maintain precise control over the manufacturing process, ensuring that the final product meets stringent industry standards. Advanced drawing machines and heat treatment processes improve the mechanical properties of the wire, making it suitable for high-stress applications.

Applications Across Industries

The versatility of 3mm low carbon cold drawn steel wire is evident in its wide range of applications. In the construction industry, it is often used in reinforced concrete, providing structural support and improving durability. In the automotive sector, it is employed in the manufacturing of components such as springs, wire harnesses, and other structural elements that demand strength and reliability. Furthermore, its applications extend to the making of fencing, agricultural equipment, and various consumer goods, showcasing its adaptability and essential role in modern manufacturing.

Future Outlook

As the demand for sustainable manufacturing solutions grows, the role of low carbon cold drawn steel wire factories is likely to increase. Industries are progressively recognizing the importance of environmentally friendly materials and processes, leading to a shift in focus towards low carbon options. The integration of green practices, such as the use of renewable energy sources in factories, can further bolster the sustainability of low carbon steel production.

In conclusion, low carbon cold drawn steel wire factories represent a crucial segment of the manufacturing industry, balancing the needs for quality, versatility, and environmental responsibility. As technology advances and sustainability becomes a priority, these factories are well-positioned to lead the charge towards a greener industrial future. Their contributions not only support various sectors but also align with global efforts to reduce the carbon footprint, making them integral to the evolving landscape of manufacturing.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025