nov . 22, 2024 11:38 Back to list

oem galvanised welded wire mesh

Understanding OEM Galvanised Welded Wire Mesh

In the realm of construction and manufacturing, the term OEM (Original Equipment Manufacturer) often signifies a partnership where one company manufactures components that are branded by another. When it comes to galvanised welded wire mesh, OEM services can significantly enhance the quality and customisation of products. This article delves into the key aspects of OEM galvanised welded wire mesh, including its composition, benefits, applications, and considerations for procurement.

What is Galvanised Welded Wire Mesh?

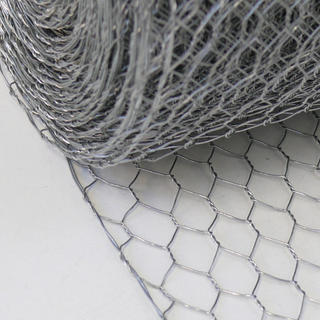

Galvanised welded wire mesh is made from high-quality steel wire that is welded together to form a grid pattern. The term galvanised refers to the process of coating the steel with zinc to protect it from corrosion. This coating not only provides outstanding durability but also enhances the aesthetic appeal of the mesh. The welded construction offers significant strength, making it suitable for a wide variety of applications.

Advantages of OEM Galvanised Welded Wire Mesh

1. Customisation One of the primary benefits of OEM galvanised welded wire mesh is the ability to customise the product to meet specific requirements. OEM manufacturers can tailor the mesh size, wire diameter, and galvanisation thickness to suit particular projects, ensuring you get exactly what you need.

2. Quality Assurance OEM suppliers are often bound by strict quality control measures. This ensures that the galvanised welded wire mesh meets industry standards and complies with regulations. Customers can have confidence in the durability and reliability of the product, reducing the likelihood of failures and promoting longevity.

3. Cost-Effectiveness By choosing an OEM supplier, companies can benefit from reduced production costs without compromising quality. OEMs often have the resources and expertise to produce materials more efficiently, resulting in savings that can be passed on to the customer.

4. Technical Support OEMs typically offer valuable technical knowledge and customer support, assisting clients in understanding the best uses and applications for galvanised welded wire mesh. This support can be crucial in complex projects requiring specific solutions.

Applications of Galvanised Welded Wire Mesh

The versatility of galvanised welded wire mesh allows for its use in numerous applications

oem galvanised welded wire mesh

- Construction It is often used in the construction industry for reinforcing concrete structures, fencing, and formwork. Its strength and durability make it ideal for providing stability to walls, roofs, and foundations. - Agriculture Farmers frequently use welded wire mesh for fencing livestock and creating enclosures for crops. The corrosion-resistant properties of galvanisation extend the life of the mesh in outdoor environments.

- Industrial Many industries utilise galvanised welded wire mesh for security applications, such as in cages, shelving, and partitions. Its ability to withstand heavy loads makes it a preferred choice for various industrial settings.

- Home and Garden Gardeners often use welded wire mesh to create trellises, plant supports, and animal barriers. Its aesthetic appeal and strength make it suitable for decorative structures as well.

Considerations for Procurement

When procuring OEM galvanised welded wire mesh, several factors should be taken into account

1. Supplier Reputation It is essential to choose a reputable OEM supplier with a track record of quality and reliability. Researching reviews and testimonials can help ensure you select a trustworthy partner.

2. Specifications Clearly define your project requirements, including dimensions, wire gauge, and coating specifications. This will help ensure that the OEM can deliver a product that meets your needs.

3. Compliance and Standards Ensure that the OEM follows relevant industry standards and regulations. This is particularly critical in construction and agricultural applications, where compliance can impact safety and effectiveness.

4. Delivery and Logistics Discuss the delivery timelines, shipping considerations, and any potential delays in advance. Understanding these aspects can help avoid project setbacks.

Conclusion

OEM galvanised welded wire mesh represents an invaluable resource across diverse industries, offering customisation, quality assurance, and cost-effectiveness. Whether used in construction, agriculture, or industrial settings, choosing the right OEM supplier can make a significant difference in the success of your projects. By understanding the benefits and applications of this versatile material, businesses can make informed decisions that enhance their operational efficiency and product performance.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025