nov . 11, 2024 05:32 Back to list

Top Suppliers of Cold Drawn Steel Bars for Your Business Needs

Understanding Cold Drawn Steel Bars A Comprehensive Guide for Suppliers

Cold drawn steel bars are essential materials used across various industries, including construction, automotive, and manufacturing. The process of cold drawing involves pulling steel through a die to reduce its diameter and improve its mechanical properties. This article provides an overview of cold drawn steel bars, their benefits, and considerations for suppliers looking to enter or excel in this competitive market.

What is Cold Drawn Steel?

Cold drawn steel is produced by deforming the steel at room temperature. This process results in increased strength and better surface finish compared to hot-rolled steel due to the strain hardening that occurs during drawing. The properties of cold drawn steel bars can be tailored to meet specific requirements, making them suitable for high-stress applications.

The Cold Drawing Process

The cold drawing process involves several steps

1. Preparation The steel bars are first cut to the required length and cleaned to ensure no contaminants interfere with the drawing process. 2. Drawing The cleaned bars are then drawn through a series of dies, which reduce the diameter of the bar while increasing its length. This step can be performed in multiple passes to achieve the desired dimensions.

3. Heat Treatment In some cases, heat treatment may be applied after cold drawing to relieve internal stresses and enhance certain properties, such as toughness and ductility.

4. Finishing Finally, the bars undergo finishing processes, including cutting, straightening, and surface treatment to enhance corrosion resistance and aesthetic appearance.

Benefits of Cold Drawn Steel Bars

1. Enhanced Mechanical Properties Cold drawn steel bars offer superior yield strength, tensile strength, and hardness, making them ideal for demanding applications.

2. Improved Surface Finish The cold drawing process leads to a smoother surface compared to hot rolled steel, reducing the need for further machining or finishing.

3. Dimensional Precision With precise control over the drawing process, suppliers can produce steel bars with tight tolerances, which is crucial for applications requiring exact specifications.

4. Reduced Manufacturing Costs The increased strength of cold drawn bars can lead to thinner sections in design, reducing material costs without compromising structural integrity.

5. Versatility Cold drawn steel bars can be produced in various shapes and sizes, including round, square, and rectangular profiles, providing suppliers with flexibility in meeting customer needs.

cold drawn steel bar supplier

Applications of Cold Drawn Steel Bars

Cold drawn steel bars find applications in a multitude of sectors

- Automotive Industry Used for components requiring high strength and durability, such as axles, shafts, and various structural parts.

- Construction Commonly employed in the manufacturing of reinforcing bars (rebar) and other components that necessitate high strength and reduced weight.

- Manufacturing Essential for producing machined parts, fasteners, and precision components across various industrial applications.

Choosing the Right Supplier

For businesses seeking to source cold drawn steel bars, choosing the right supplier is critical. Here are some factors to consider

1. Quality Assurance Look for suppliers that adhere to strict quality control measures and certifications to ensure the steel meets industry standards.

2. Production Capabilities Assess whether the supplier can meet your specific dimensions and tolerances and whether they can scale production to meet demand.

3. Lead Times and Availability Reliable suppliers should have a good track record of timely deliveries and stock availability to avoid disruptions in your supply chain.

4. Technical Support A knowledgeable supplier will provide not just the steel bars but also support in material selection and application guidance.

5. Sustainability Practices In today’s market, many businesses prioritize sourcing materials from suppliers with eco-friendly practices. Consider suppliers who demonstrate a commitment to sustainability.

Conclusion

Cold drawn steel bars are invaluable materials that enhance performance in various applications due to their superior mechanical properties and precision. For suppliers, understanding the nuances of the cold drawing process, the benefits it offers, and the importance of quality assurance can pave the way for success in this competitive marketplace. By focusing on customer needs and maintaining high standards, suppliers can secure their position as trusted partners in industries reliant on high-quality steel products.

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025

-

Chain Link Fence - Anping County Puersen|Durable, Versatile Fencing

NewsAug.02,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable,Versatile,Reliable

NewsAug.02,2025

-

Chain Link Fence-Durable Construction&Versatile Applications | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.02,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable

NewsAug.02,2025

-

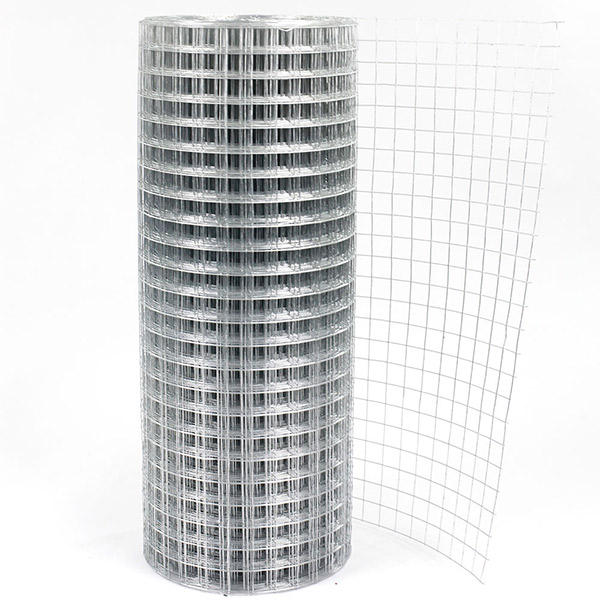

Welded Wire Mesh for Industrial Factory | Strength & Durability

NewsAug.02,2025