Sep . 07, 2024 18:54 Back to list

Reinforcement Concrete Welded Wire Mesh Panels - Durable & Reliable Solutions

Reinforcement Concrete Welded Wire Mesh Panels An Overview

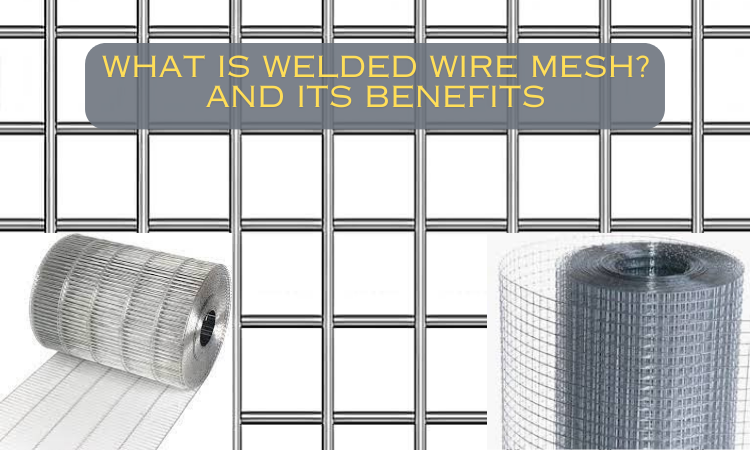

Reinforcement concrete welded wire mesh panels have become a crucial component in modern construction practices, offering enhanced structural integrity, durability, and efficiency. These panels consist of a grid of high-strength steel wires that are welded together at intersections, forming a rigid frame to support concrete applications. This innovative building material has gained traction in various sectors, including residential, commercial, and industrial construction.

One of the primary advantages of using welded wire mesh panels is their ability to distribute loads evenly across surfaces. When incorporated into concrete structures, they effectively resist tension and shear forces, improving the overall strength of the slab or wall. The uniform distribution of stress minimizes the chances of cracking and structural failure, making it an essential aspect of reinforced concrete design.

Additionally, these panels are produced in various sizes and configurations, allowing for versatility in application. Builders can select the appropriate mesh type based on specific project requirements, including load-bearing capacities and environmental conditions. The typical wire diameter ranges from 3 to 8 mm, and the spacing between the wires can vary, ensuring that designers can optimize the material for different uses.

reinforcement concrete welded wire mesh panel

Installation of welded wire mesh panels is relatively straightforward, enhancing construction speed and efficiency. They can be laid directly onto the formwork before pouring concrete, ensuring that the mesh becomes an integral part of the structure as the concrete cures. Furthermore, using mesh panels helps reduce labor costs associated with manual reinforcement methods, as they eliminate the need for tying individual rebar pieces together.

In terms of durability, welded wire mesh panels exhibit excellent corrosion resistance when properly coated or treated. This characteristic is particularly vital in environments exposed to moisture or harsh conditions, such as coastal areas or regions with heavy rainfall. By extending the lifespan of concrete structures, these panels provide long-term economic benefits, reducing the need for repairs and maintenance.

Moreover, the use of welded wire mesh in construction aligns with sustainable building practices. By optimizing the amount of concrete and steel used in structures, builders can reduce waste and minimize the carbon footprint associated with construction activities. This aspect is increasingly important in today's market, as the construction industry shifts toward environmentally responsible practices.

In conclusion, reinforcement concrete welded wire mesh panels are a valuable addition to contemporary construction techniques. Their ability to enhance structural integrity, improve efficiency, and support sustainability makes them an attractive option for builders and engineers alike. As construction technologies continue to evolve, the role of welded wire mesh panels is likely to expand, contributing to safer, more resilient built environments.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025