stu . 30, 2024 10:58 Back to list

Factories Producing High-Quality Reinforcing Wire Mesh A193 for Construction Industry

Reinforcing Wire Mesh A193 Understanding its Importance and Manufacturing

Reinforcing wire mesh plays a crucial role in the construction industry. Among the various types available, A193 wire mesh stands out due to its specific properties and applications. Understanding the manufacturing processes and the significance of this product can provide valuable insights for professionals in construction and engineering.

What is Reinforcing Wire Mesh A193?

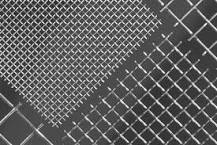

Reinforcing wire mesh A193 is a welded steel wire fabric that is used primarily for reinforcing concrete structures. The designation A193 refers to a particular standard established by organizations like ASTM (American Society for Testing and Materials). This standard defines the mechanical properties, dimensions, and quality of the wire used, ensuring that it meets the necessary strength and durability requirements for construction projects.

The mesh is typically made of high-quality steel, which contributes to its strength and stability. The wires are welded at their intersections to provide a grid that can effectively distribute loads and resist cracking in concrete. As a result, A193 wire mesh is widely used in foundations, slabs, walls, and various other concrete structures.

Manufacturing Process

The manufacturing of reinforcing wire mesh A193 involves several key steps

1. Wire Production The process begins with the creation of steel wire. The steel is melted and subjected to various treatments to achieve the desired chemical composition and mechanical properties. Once the steel reaches the requisite specifications, it is drawn into wire through a series of dies.

2. Mesh Formation After the wire is produced, it is cut to the required lengths and arranged in a grid pattern. The wires are placed at right angles to each other, forming a series of squares or rectangles.

3. Welding The final step involves welding the wires at their intersections. This is typically done using a resistance welding method, which applies heat and pressure to bond the wires together. This method not only provides a strong connection at each joint but also allows for efficient mass production of wire mesh sheets, ensuring uniform quality.

reinforcing wire mesh a193 factories

4. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. Tests are conducted to ensure that the finished wire mesh meets the specifications outlined in the A193 standard, including tensile strength and weld integrity.

Applications of A193 Wire Mesh

The A193 reinforcing wire mesh is utilized in a wide range of applications within the construction sector. Some of its most common uses include

- Slab Reinforcement It is often used in concrete slabs, providing enhanced load distribution and crack resistance. This is especially important in areas with heavy foot or vehicular traffic.

- Foundation Support A193 wire mesh can reinforce concrete foundations, ensuring stability and strength over time. This is critical in preventing settlement issues in buildings.

- Wall Construction It is employed in both load-bearing and non-load-bearing walls, adding strength and preventing the formation of cracks.

- Paving In pavement projects, A193 wire mesh improves the durability of the surface, extending the lifespan of roads and highways.

Conclusion

Reinforcing wire mesh A193 is an essential component of modern construction, providing the strength and stability necessary for long-lasting concrete structures. Understanding its manufacturing process highlights the quality and care that go into producing this vital material. As the construction industry continues to evolve, the role of A193 wire mesh in ensuring structural integrity will remain paramount. Its widespread applications throughout various construction projects underscore its importance in delivering safe and reliable infrastructure.

-

Premium Gabion Welded Wire Mesh High-Strength & Corrosion-Resistant

NewsJun.06,2025

-

Premium Concrete Reinforcing Mesh Direct from Chinese Suppliers

NewsJun.06,2025

-

Premium Black Nail Wire Suppliers - Durable & Corrosion Resistant

NewsJun.06,2025

-

Steel Fence Posts & Railing Designs Premium Metal Fencing Solutions

NewsJun.05,2025

-

Premium Perforated Metal Sheets Custom Sizes & Quality

NewsJun.05,2025

-

Precision 8mm Cold Drawn Wire Suppliers High Strength & Quality

NewsJun.04,2025