pro . 04, 2024 07:12 Back to list

binding iron wire factory

The Craft of Binding Iron Wire A Journey Through the Factory

In the heart of industrial manufacturing, there exists a specialized craft that plays an essential role in various applications the binding of iron wire. Factories dedicated to this process are vital nodes in the supply chain, providing the necessary materials for construction, agriculture, and other industries. In this article, we will explore the intricacies of an iron wire binding factory, the technology involved, and the significance of this trade within the modern economy.

The Foundations of Iron Wire Binding

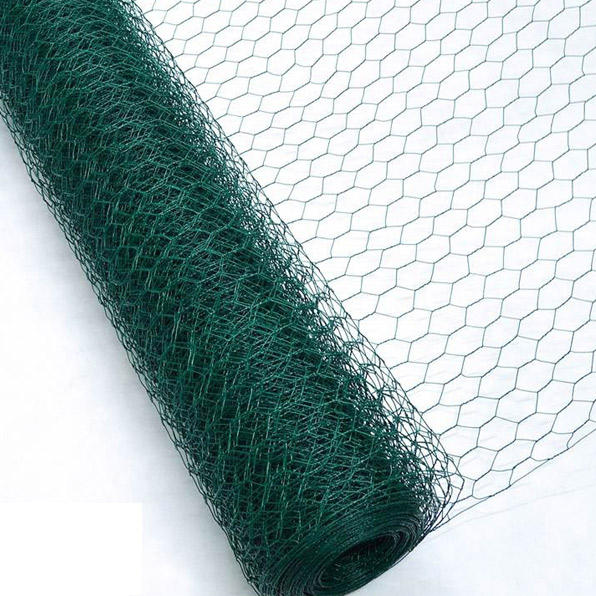

Iron wire binding is a process that involves shaping and reinforcing iron wire to create durable and reliable products. This process is critical for a variety of industries, including construction, where iron wire is used for reinforcing concrete, and agriculture, where it serves as a reliable fencing solution. At the outset, high-quality raw materials are sourced, often in the form of large coils of iron wire. The initial quality of the wire is foundational, as it determines the strength and durability of the final product.

The Manufacturing Process

The production process in an iron wire binding factory typically follows several stages. It begins with unwinding the coils of iron wire. The factory floor is a cacophony of machines, each performing a distinct function in the binding process. The wire is cut to length, twisted, and sometimes coated to enhance its resistance to rust and corrosion. Various techniques are employed, including manual binding by skilled workers and automated machinery that ensures high precision and efficiency.

One of the key stages in the binding process is the formation of the wire into specific shapes or configurations. This can include rolling, bending, or twisting the wire into knots or loops, depending on the intended use. The versatility of iron wire allows it to be molded into a range of shapes, each catering to different applications.

Additionally, quality control is paramount in this industry. Each batch of iron wire must undergo rigorous testing to ensure it meets the stringent standards required for durability and performance. Tests for tensile strength, elasticity, and corrosion resistance are common practice, safeguarding the durability of the products manufactured.

binding iron wire factory

Technological Advances

In recent years, technological advancements have revolutionized the way iron wire is bound. Automation has transformed many aspects of the manufacturing process, enabling factories to produce higher volumes with greater efficiency. Techniques such as computer numerical control (CNC) machining allow for precision cutting and shaping that reduces waste and enhances consistency.

Moreover, the integration of smart technology has improved inventory management and production scheduling. Factories can now track real-time data on supply levels, production rates, and machine performance, which aids in optimizing operations and reducing downtimes. These advancements not only improve efficiency but also have environmental benefits, as they often reduce energy consumption and waste generation.

The Economic Significance

The importance of binding iron wire factories in the global economy cannot be overstated. They provide essential materials that support construction and agricultural sectors, contributing to infrastructure development and food security. By supplying high-quality iron wire, these factories play a crucial role in fostering economic growth and stability.

Moreover, the iron wire binding industry supports numerous jobs, from skilled labor in manufacturing to engineering roles focused on improving production processes. The ripple effect of this industry impacts various sectors, enhancing the overall robustness of manufacturing ecosystems.

Conclusion

The intricate process of binding iron wire exemplifies the blend of traditional craftsmanship and modern technology. Iron wire binding factories are at the forefront of industrial manufacturing, producing materials that are foundational to numerous industries. As technology continues to evolve, the efficiency and quality of iron wire production will only improve, solidifying its role in supporting global economic frameworks. Understanding the significance of this craft not only highlights the importance of the factories themselves but also acknowledges the skilled workers who keep this vital industry moving forward. In the end, the humble iron wire is a reminder of the complexities behind even the simplest of materials, illustrating a world driven by innovation and craftsmanship.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025