नवम्बर . 19, 2024 22:38 Back to list

sl62 welded wire mesh factory

The Importance of SL62% Welded Wire Mesh in Modern Construction

In the realm of modern construction and civil engineering, the choice of materials can significantly affect the durability and strength of structures. One such material that has gained immense popularity is welded wire mesh, particularly the SL62% variant. This article delves into the significance of SL62% welded wire mesh, its manufacturing process, benefits, and applications, showcasing why it's a preferred choice for construction projects.

Understanding SL62% Welded Wire Mesh

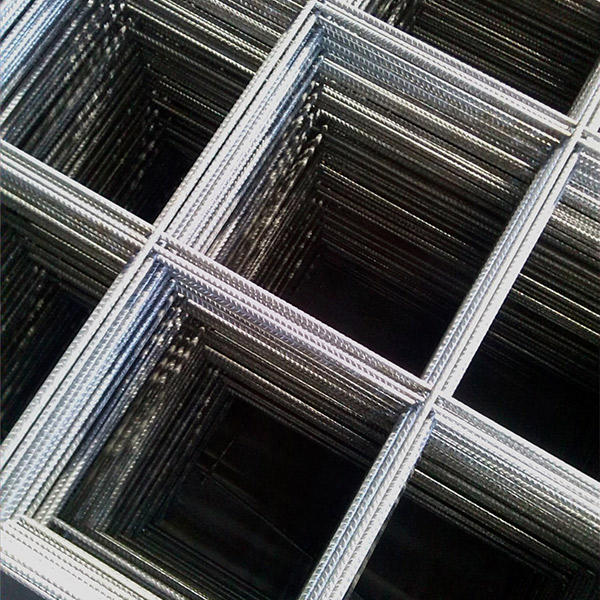

SL62% welded wire mesh is a type of reinforcement mesh made from high-quality steel wire. It consists of longitudinal and transverse wires that are welded together at their intersections. The term SL62% refers to the specific percentage of the reinforcement area it provides, which is crucial in certain construction methods to ensure adequate structural integrity.

The wire diameter typically ranges from 5mm to 10mm, depending on specific project requirements. The mesh is produced in various sizes and can be tailored to meet the needs of diverse construction situations. Its design allows for quick and easy installation, making it a favored option among contractors and builders.

Manufacturing Process

The manufacturing process of SL62% welded wire mesh involves several critical steps

1. Wire Production High-quality steel is drawn into wires of predetermined diameters. This wire must meet specific mechanical properties to ensure strength and durability.

2. Welding The wires are then arranged in specific grids, and the intersections are welded together using advanced welding techniques. This creates a robust mesh structure capable of withstanding various stresses.

3. Quality Control After production, the welded wire mesh undergoes stringent quality control tests. These tests check for weld integrity, wire alignment, and overall mesh strength, ensuring the final product meets industry standards.

4. Surface Treatment To enhance durability and corrosion resistance, the mesh may undergo surface treatments such as galvanization or coating. This step is especially important in environments exposed to moisture or chemicals.

Benefits of SL62% Welded Wire Mesh

1. Strength and Durability SL62% welded wire mesh provides excellent tensile strength, making it ideal for reinforcing concrete slabs, floors, walls, and foundations. Its structural integrity helps in distributing loads evenly, reducing the risk of cracks and structural failure.

sl62 welded wire mesh factory

2. Cost-Effective Solution Compared to traditional reinforcement methods, using welded wire mesh can be more economical. It often requires fewer materials and less labor during installation, which can lead to significant cost savings on construction projects.

3. Ease of Installation The pre-manufactured nature of welded wire mesh allows for quick installation. Builders can easily roll out or lay the mesh into forms, significantly accelerating project timelines.

4. Design Versatility SL62% welded wire mesh can be tailored in size and shape, allowing for versatility in design. It can be customized for different applications, ensuring that it meets the specific needs of each project.

5. Environmental Benefits Steel is a recyclable material, and many manufacturers focus on environmentally friendly production practices. By choosing welded wire mesh, builders can contribute to sustainable construction efforts.

Applications of SL62% Welded Wire Mesh

The applications of SL62% welded wire mesh are vast and varied, including

- Concrete Reinforcement It is primarily used to reinforce concrete in slabs, beams, and floor systems, providing the necessary strength to support heavy loads.

- Fencing and Enclosures SL62% welded wire mesh is used for fencing applications, offering security and visibility while being robust enough to withstand environmental elements.

- Industrial Applications It is employed in various industrial applications, including loading docks, walkways, and protective barriers.

- Agricultural Use The mesh is also utilized in agricultural settings for livestock enclosures and crop support structures.

Conclusion

In summary, SL62% welded wire mesh is an essential material in contemporary construction. Its exceptional strength, durability, and versatility make it a go-to solution for a wide range of applications. With ongoing advancements in manufacturing techniques and a growing focus on sustainability, the use of SL62% welded wire mesh is poised to continue expanding in the coming years. Whether for large-scale infrastructure projects or smaller residential builds, this welded wire mesh remains an invaluable asset in the construction industry.

-

High Quality Galvanized Wire Brick Force Mesh - Reliable Manufacturers & Suppliers

NewsJul.05,2025

-

Concrete Reinforcing Roll Welded Wire Mesh – Durable & High Strength Reinforcement Mesh from Leading Factories

NewsJul.05,2025

-

High Quality PVC Coated 2x1x1 Gabion Boxes - Durable, Corrosion Resistant, Direct from Manufacturer

NewsJul.05,2025

-

High Quality Roll Welded Wire Mesh for Concrete Reinforcing BWG22 Galvanized Mesh Rolls Factory Direct

NewsJul.04,2025

-

High Quality Deformed Steel Bars China - Leading Manufacturers & Suppliers

NewsJul.04,2025

-

12mm Stainless Steel Wire Mesh for Industrial & Commercial Use Top Quality Factories & Manufacturers

NewsJun.24,2025