דצמ . 27, 2024 08:43 Back to list

wire mesh rolls factories

Understanding Wire Mesh Rolls Factories A Comprehensive Overview

Wire mesh rolls have become an essential component across various industries, thanks to their versatility, durability, and cost-effectiveness. From construction and agriculture to manufacturing and transportation, wire mesh rolls are integral to ensuring structural integrity and safety. This article will explore the key aspects of wire mesh rolls factories, including their production processes, types of wire mesh, and the industries they serve.

The Production Process

Wire mesh rolls are produced in specialized factories that focus on the weaving and manufacturing of metal wire. The production process typically involves several stages

1. Wire Generation The first step in creating wire mesh is generating wire from metal materials, such as steel, stainless steel, or galvanized iron. This wire is produced in various gauges, depending on the intended application.

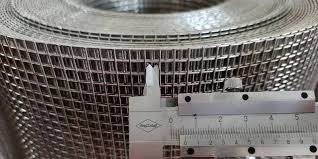

2. Weaving Once the wire is ready, it is fed into weaving machines that interlace the wire to form the mesh. The weaving process can be done using different patterns, such as square, rectangular, or hexagonal, allowing for various mesh sizes and configurations.

3. Coating Depending on the desired application, sometimes the mesh is treated with protective coatings. For instance, galvanized wire mesh is coated with zinc to prevent rust and corrosion, significantly extending its life span. Other coatings may include PVC for enhanced durability and environmental resistance.

4. Cutting and Rolling After weaving and coating, the mesh is cut into specific sizes and rolled for packaging. This ensures that customers can easily handle and transport the wire mesh rolls to their respective sites.

5. Quality Control A crucial aspect of the production process involves rigorous quality control checks. Factories often employ strict testing methods to ensure the product meets industry standards regarding strength, durability, and flexibility.

Types of Wire Mesh

Wire mesh rolls come in various types, each designed for specific applications

- Welded Wire Mesh This type is produced by welding intersecting wires at each joint, resulting in a strong and stable structure. Welded wire mesh is commonly used in construction for reinforcing concrete, fencing, and manufacturing cages.

wire mesh rolls factories

- Chain Link Fencing A popular choice for security applications, this type of mesh is made from high-tensile wire woven into a diamond pattern. Chain link fencing is widely utilized in residential, commercial, and industrial settings.

- Stainless Steel Wire Mesh Known for its corrosion resistance, stainless steel wire mesh is frequently used in food processing, medical applications, and environments where hygiene is critical.

- Hexagonal Wire Mesh Often referred to as chicken wire, this mesh is typically used in poultry enclosures and garden fencing. Its hexagonal shape provides flexibility and durability, making it suitable for various agricultural applications.

Industries Served

Wire mesh rolls are crucial across a multitude of industries

- Construction In the construction industry, wire mesh is widely used for reinforced concrete, ensuring structural integrity in buildings, roads, bridges, and other infrastructure projects.

- Agriculture Farmers utilize wire mesh for fencing livestock, protecting crops, and creating enclosures, making it ideal for rural and farming applications.

- Manufacturing The manufacturing industry relies on wire mesh for filtering, sieving materials, and constructing storage and transportation solutions. Applications may include automotive, aerospace, and food processing.

- Security In security applications, wire mesh rolls are employed for fencing around properties, creating barriers, and building safety grilles.

Conclusion

Wire mesh rolls factories play a critical role in supplying various industries with essential materials. Through advanced production processes and strict quality control measures, these factories ensure that their products meet the highest standards of durability and functionality. As industries continue to evolve and expand, the demand for wire mesh rolls will likely grow, solidifying their importance within the global market. Understanding the intricacies of wire mesh production and its applications helps appreciate the impact these factories have on both local economies and broader industrial practices.

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025