דצמ . 04, 2024 17:55 Back to list

welded wire mesh for lawn factories

The Importance of Welded Wire Mesh for Lawn Factories

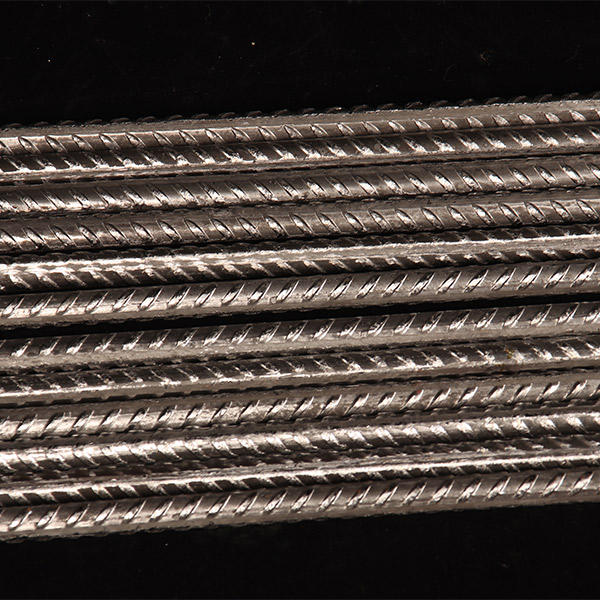

Welded wire mesh is an essential component in the manufacturing processes of lawn factories, providing both structural integrity and functional benefits that are critical to operations in the landscaping and gardening industry. This versatile material is manufactured by welding together intersecting wires, creating a grid-like structure that is not only durable but also offers flexibility in its applications.

Durability and Strength

One of the key advantages of welded wire mesh is its durability. Made from high-quality steel or stainless steel, it can withstand various environmental conditions, making it ideal for outdoor use. Lawn factories often utilize this material for reinforcement in various products, such as fencing, garden beds, and storage shelves. Its robust design ensures that it can bear heavy loads without deforming or breaking, making it a reliable choice for building long-lasting structures.

Versatile Applications

Welded wire mesh is incredibly versatile, which allows it to be used in various applications within lawn factories. For instance, it can be used to support the growth of climbing plants and vegetables by providing a sturdy framework. Additionally, it is commonly employed in the construction of greenhouses, ensuring that plants can flourish in a safe and controlled environment. Moreover, its application in lawn maintenance equipment storage solutions helps keep gardens organized and equipment accessible, contributing to efficient operations within factories.

Cost-Effectiveness

welded wire mesh for lawn factories

In an era where cost management is crucial, welded wire mesh proves to be a cost-effective solution for lawn factories. Its manufacturing process allows it to be produced in bulk, which lowers overall costs. The longevity of welded wire mesh also contributes to reduced maintenance and replacement expenses over time. By investing in quality welded wire mesh, lawn factories can focus their resources on other important areas of their operations while enjoying the benefits of a reliable material.

Customizability

Welded wire mesh can be easily customized to meet specific requirements, making it an excellent choice for lawn factories that need tailored solutions. Customers can choose various wire gauges, mesh sizes, and coatings, such as vinyl or galvanized finishes, which enhance corrosion resistance and longevity. This customizability ensures that lawn factories can use welded wire mesh in unique applications, from intricate decorative elements to robust supporting structures.

Environmental Considerations

Sustainability is becoming a significant focus in manufacturing processes, and welded wire mesh aligns with this shift. Many manufacturers are now producing welded wire mesh with eco-friendly practices, and the steel used can often be recycled. This aspect is particularly appealing for lawn factories aiming to minimize their environmental impact while ensuring that they are providing high-quality products to their clients.

Conclusion

In conclusion, welded wire mesh is a fundamental material for lawn factories, combining durability, versatility, cost-effectiveness, and customizability. Its applications range from structural reinforcement to aiding in plant growth, ensuring that lawn factories can operate efficiently while delivering high-quality products. As the landscaping and gardening industry continues to evolve, welded wire mesh will undoubtedly remain a pivotal component, helping factories meet the growing demands of their customers while adhering to principles of sustainability. Investing in this essential material now will not only enhance operations but also pave the way for a successful future in the lawn care industry.

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025