Dec . 09, 2024 17:35 Back to list

Wire Mesh Rolls Manufacturer for Versatile Applications and Solutions

Wire Mesh Rolls Factory Innovations and Applications in Modern Manufacturing

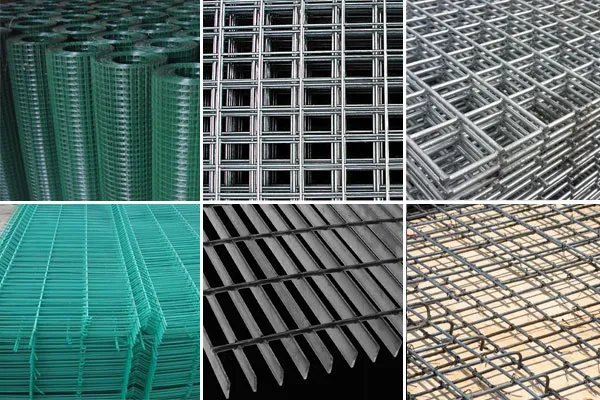

In the era of advanced manufacturing and construction technologies, wire mesh rolls have become essential products in various industries. These rolls are versatile materials commonly used in construction, agriculture, and industrial applications. A wire mesh rolls factory specializes in the production of these materials, providing businesses with the quality and strength required for their diverse needs. This article delves into the operations, innovations, and applications of wire mesh rolls produced in such factories.

Understanding Wire Mesh Rolls

Wire mesh rolls are made from woven or welded wire strands, creating a grid-like structure that offers substantial strength and flexibility. The materials used can vary, with options including stainless steel, galvanized steel, and various other alloys designed to withstand environmental stresses. The design and specification of these rolls can be tailored to meet specific requirements, including different mesh sizes, wire gauges, and roll dimensions.

The Role of Wire Mesh Rolls Factories

Wire mesh rolls factories play a critical role in the supply chain of various industries. They employ advanced machinery and skilled labor to manufacture high-quality wire mesh products that meet international standards. Most factories employ a range of production techniques, including weaving and welding, to create the required mesh configurations. Quality control is essential in this manufacturing process, ensuring that every roll produced is free from defects and meets customer specifications.

Innovations in Manufacturing Processes

With technological advancements, wire mesh rolls factories have adopted innovative manufacturing processes that enhance efficiency and reduce waste. Automation is a significant trend, with machines that can produce wire mesh rolls at faster rates and with greater precision. Furthermore, factories are now integrating computer numerical control (CNC) technology to ensure consistent quality across batches.

In addition to automation, sustainable practices have gained traction in wire mesh production. Many factories are sourcing raw materials from recycled sources, thereby minimizing the environmental impact associated with mining and metalwork. Implementing energy-efficient manufacturing processes not only reduces costs but also promotes sustainability within the industry.

Applications of Wire Mesh Rolls

wire mesh rolls factory

Wire mesh rolls have a multitude of applications across various sectors

1. Construction In the construction industry, wire mesh is widely used for reinforcement in concrete, fencing, and as a barrier to prevent soil erosion. The material adds strength to structures, ensuring durability and longevity.

2. Agriculture Farmers utilize wire mesh rolls for livestock enclosures, crop protection, and fencing. The sturdy nature of wire mesh provides a reliable means to protect crops from pests and animals, while also allowing for ventilation and sunlight penetration.

3. Industrial Uses Many industries employ wire mesh for filtration, sorting, and safety applications. For instance, wire mesh filters are crucial in wastewater treatment plants, while safety screens are instrumental in machinery to prevent accidents.

4. Architecture and Design Wire mesh has also found a place in modern architecture and interior design. It is often used in facades, railings, and partitions, offering both aesthetic appeal and functional support.

Challenges and Solutions

Despite its versatility, the wire mesh industry faces several challenges. Fluctuating raw material prices can impact production costs, while competition from cheaper imports poses a threat to domestic manufacturers. To combat these challenges, factories are focusing on enhancing their value proposition through innovation, customer service, and customized solutions tailored to meet specific client needs.

Moreover, investing in research and development enables factories to explore new applications for wire mesh, expanding their market reach and establishing a competitive edge.

Conclusion

In conclusion, wire mesh rolls factories are integral to the evolving landscape of manufacturing and construction industries. Through innovative manufacturing processes, commitment to quality, and a focus on sustainability, these factories are poised to meet the growing demands of various sectors. As industries continue to adapt to new challenges and technologies, the role of wire mesh rolls will undoubtedly expand, making them indispensable in future developments. With an unwavering dedication to excellence, wire mesh rolls factories will continue to provide the strength, durability, and reliability that modern construction and manufacturing require.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025