Dec . 04, 2024 13:15 Back to list

SL72% Welded Wire Mesh for Versatile Construction and Durable Reinforcement Applications

Understanding SL72% Welded Wire Mesh Applications and Benefits

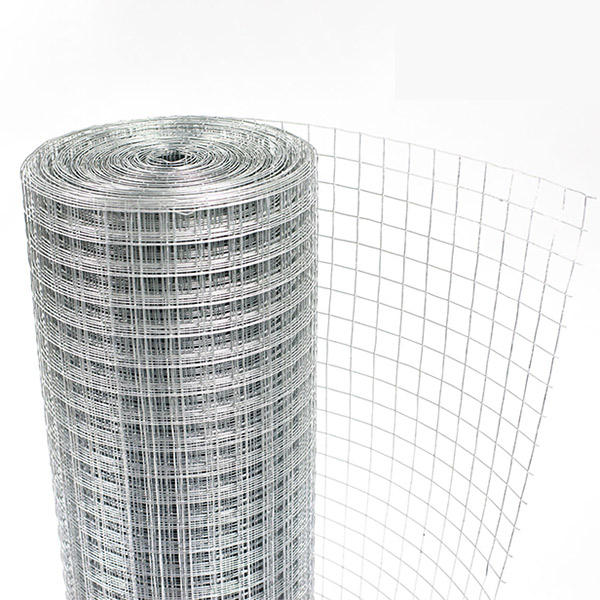

Welded wire mesh, particularly the SL72% variety, is an essential product in the construction and engineering industries. Comprised of steel wires that are welded together to form a strong, grid-like structure, this type of mesh has become increasingly popular due to its versatility, durability, and cost-effectiveness. In this article, we will explore the characteristics, applications, and advantages of SL72% welded wire mesh.

What is SL72% Welded Wire Mesh?

SL72% welded wire mesh refers to a specific type of mesh that uses steel wires of designated diameters welded together at various spacing intervals. The SL stands for “stainless and welded,” and the 72% indicates the percentage of the mesh area occupied by the wires. This design ensures superior strength and stability, making it suitable for a wide range of applications. The mesh is commonly available in sheets that can be easily transported and installed on various projects.

Key Characteristics

One of the distinguishing features of SL72% welded wire mesh is its high tensile strength. This makes it ideal for reinforcing concrete structures, as it withstands both tension and compression forces. Additionally, the welded design provides consistent spacing and alignment between wires, leading to uniformity in strength and appearance. The mesh is generally galvanized or coated to enhance its resistance to corrosion, thereby extending its lifespan and reducing maintenance costs.

Applications

The applications of SL72% welded wire mesh are vast and varied. Here are some common uses

1. Concrete Reinforcement One of the primary uses of SL72% welded wire mesh is in reinforced concrete applications. It provides internal support, helping to distribute loads evenly and prevent cracking.

2. Road Construction This type of mesh is frequently used in the construction of roads and highways, providing stability and integrity to the pavement structure.

sl72 welded wire mesh

4. Retaining Walls In projects involving soil retention, welded wire mesh serves as a critical element in constructing retaining walls, offering strength and reliability.

5. Animal Enclosures and Fencing Beyond construction, this mesh can also be used for fencing, animal enclosures, or garden barriers. Its strength ensures safety and security for livestock and property.

Advantages

The use of SL72% welded wire mesh comes with numerous advantages

- Cost-Efficiency Compared to traditional rebar or other reinforcement methods, welded wire mesh often proves to be more cost-effective, reducing both materials and labor costs.

- Ease of Installation The lightweight nature of the mesh allows for easier handling and installation compared to heavier materials. This can lead to savings in labor time and costs.

- Durability Given its coated nature and robust design, SL72% welded wire mesh is highly resistant to damage and corrosion, making it a long-lasting choice for construction projects.

- Versatility Its broad range of applications means it can be used in various projects, from residential homes to large-scale infrastructure works.

Conclusion

In summary, SL72% welded wire mesh is a vital material in modern construction and engineering. Its high strength, durability, and versatility make it suitable for numerous applications, from concrete reinforcement to fencing. By choosing SL72% welded wire mesh, builders and engineers can ensure reliable performance, cost efficiency, and longevity in their projects. As construction technology continues to advance, the importance of robust materials like SL72% welded wire mesh cannot be overstated, paving the way for innovative construction methods and enhanced structural integrity.

-

Premium Welded Reinforcing Mesh SL62/SL72/SL82 High-Strength Solutions

NewsJun.01,2025

-

Diamond Mesh Expanded Sheet Factories Durable & High-Strength Design

NewsJun.01,2025

-

REO Mesh Solutions High-Quality Manufacturers & Trusted Suppliers

NewsJun.01,2025

-

SL72 Reinforcing Fabric Factories & Suppliers High-Strength Material

NewsMay.31,2025

-

Electro Galvanized Wire Low Price Durable & Affordable Suppliers

NewsMay.31,2025

-

Steel Driveway Grates Grating - Heavy-Duty & Custom Sizes

NewsMay.31,2025