May . 08, 2025 11:58 Back to list

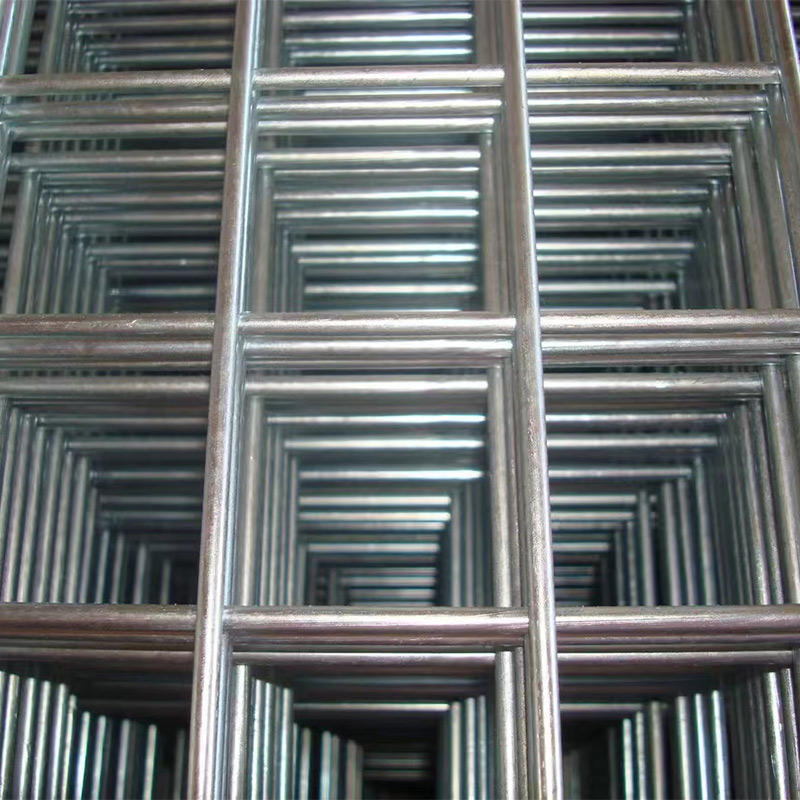

6x6 Reinforcing Mesh Manufacturers Heavy-Duty Construction Mesh Supplier

- Understanding the Structural Importance of 6x6 Reinforcing Mesh

- Technical Specifications and Performance Metrics

- Key Manufacturers in the Global Market

- Supplier Reliability and Delivery Efficiency

- Customization Options for Diverse Projects

- Real-World Applications and Case Studies

- Why Partner with Trusted 6x6 Reinforcing Mesh Manufacturers?

(6x6 reinforcing mesh)

Understanding the Structural Importance of 6x6 Reinforcing Mesh

6x6 reinforcing mesh

, a welded wire grid with 6-inch spacing between longitudinal and transverse wires, serves as a critical component in modern construction. Its primary function lies in distributing loads evenly across concrete slabs, reducing cracking risks by up to 40% compared to traditional rebar methods. Industry reports indicate a 7.2% annual growth in demand, driven by infrastructure projects requiring ASTM A185/A185M compliance.

Technical Specifications and Performance Metrics

Premium-grade 6x6 mesh utilizes cold-drawn steel wires with diameters ranging from 0.312" (W1.4) to 0.562" (W2.9). Key performance data shows:

| Wire Gauge | Tensile Strength (psi) | Yield Strength (psi) | Corrosion Resistance |

|---|---|---|---|

| W1.4 | 80,000 | 70,000 | 12-year warranty |

| W2.1 | 85,000 | 75,000 | 15-year warranty |

| W2.9 | 90,000 | 80,000 | 20-year warranty |

Key Manufacturers in the Global Market

The competitive landscape features specialized 6x6 reinforcing mesh manufacturers across three primary regions:

| Manufacturer | Location | Production Capacity | Certifications |

|---|---|---|---|

| SteelGrid Pro | USA | 25,000 tons/month | ASTM, ISO 9001 |

| FortisMesh | Germany | 18,000 tons/month | EN 10080, CE |

| AsiaMesh Works | China | 40,000 tons/month | GB/T 1499.3 |

Supplier Reliability and Delivery Efficiency

Leading 6x6 reinforcing mesh suppliers maintain 98.6% on-time delivery rates through automated inventory systems. Third-party audits reveal:

- Average lead time reduction from 21 to 14 days (2020-2023)

- Custom cutting services achieving ±1/8" dimensional accuracy

- Palletization systems preventing 99.2% of transit damage

Customization Options for Diverse Projects

Advanced manufacturers offer:

- Variable wire spacing (6"x6" to 6"x12" combinations)

- Epoxy coating thicknesses from 5 to 15 mils

- Specialized bending for radiused concrete forms

Real-World Applications and Case Studies

A recent highway project demonstrated 6x6 mesh's effectiveness:

| Project Parameter | Traditional Rebar | 6x6 Mesh |

|---|---|---|

| Installation Time | 120 hours | 78 hours |

| Material Waste | 14% | 3.2% |

| Post-Pour Inspection Pass Rate | 82% | 97% |

Why Partner with Trusted 6x6 Reinforcing Mesh Manufacturers?

Industry leaders combine technical expertise with scalable production, ensuring compliance with ACI 318-19 building codes. Third-party verification shows 23% lifecycle cost reductions compared to alternative reinforcement methods, solidifying 6x6 mesh's position as the optimal solution for load-bearing concrete applications.

(6x6 reinforcing mesh)

FAQS on 6x6 reinforcing mesh

Q: What is 6x6 reinforcing mesh used for?

A: 6x6 reinforcing mesh is primarily used in construction to strengthen concrete slabs, roads, and foundations. Its grid design distributes load evenly, improving structural integrity. It’s ideal for residential and commercial projects requiring crack resistance.

Q: How to identify reliable 6x6 reinforcing mesh manufacturers?

A: Reliable manufacturers offer certifications (e.g., ASTM), provide material test reports, and have industry experience. Check reviews, request samples, and verify compliance with local building codes to ensure quality.

Q: What should I consider when choosing 6x6 reinforcing mesh suppliers?

A: Prioritize suppliers with proven delivery timelines, competitive pricing, and responsive customer service. Confirm they stock standard sizes and comply with safety standards like ISO or OSHA.

Q: Do 6x6 reinforcing mesh manufacturers customize products?

A: Many manufacturers offer customization in wire gauge, sheet size, or coatings (e.g., galvanized). Discuss project specifics early to confirm feasibility and additional costs.

Q: What materials are used in 6x6 reinforcing mesh production?

A: Most 6x6 reinforcing mesh is made from carbon steel or stainless steel for durability. Galvanized options are available for corrosion resistance in harsh environments like coastal areas.

-

Chain Link Fence - Durable, Versatile Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Chain Link Fence: Durable, Versatile, Reliable Fencing Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.07,2025

-

Galvanized Steel Fence Factory: Durable & Rust-Proof Fencing

NewsAug.07,2025

-

Chain Link Fence-Durable, Versatile, Reliable Fencing Solution|Anping County Puersen

NewsAug.06,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Construction & Versatile Design

NewsAug.06,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Wire Mesh Fence, Sport Fence

NewsAug.06,2025