Nov . 10, 2024 00:05 Back to list

SL62 Welded Wire Mesh Production Processes and Factory Insights

The Significance of SL62% Welded Wire Mesh Factories

Welded wire mesh, particularly the SL62% variety, has become a fundamental material across numerous industries due to its versatility, strength, and durability. Factories that specialize in the production of SL62% welded wire mesh play a pivotal role in supplying this essential building block for construction, agriculture, and various industrial applications.

What is SL62% Welded Wire Mesh?

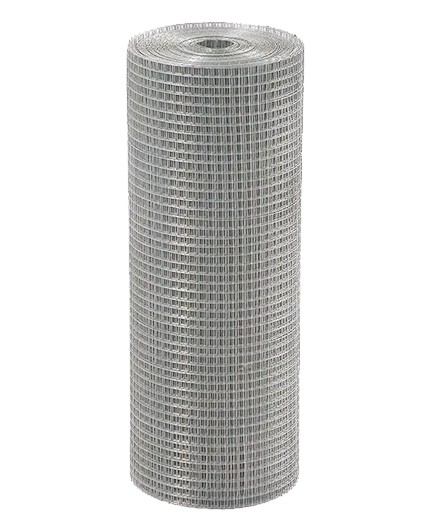

SL62% welded wire mesh refers to a specific type of wire mesh characterized by its well-defined grid structure, which is achieved through the intersection of horizontal and vertical wires that are electrically fused together. This fusion process ensures a high level of structural integrity and resistance to deformation, making it an ideal choice for reinforcing concrete and providing security in fencing applications.

The 62% in SL62% indicates the percentage of steel wire used in the mesh, highlighting its robust nature. This proportion contributes to its load-bearing capabilities, making it suitable for high-stress environments. From reinforced concrete floors and walls to agricultural fencing and animal enclosures, the applications of SL62% welded wire mesh are vast.

Advantages of SL62% Welded Wire Mesh

1. Strength and Durability One of the most significant advantages of SL62% welded wire mesh is its inherent strength. The welded joints create a robust bond that enhances the overall durability of the structure, making it capable of withstanding heavy loads and adverse weather conditions.

2. Cost-Effective Solution In construction and industrial applications, cost efficiency is always a priority. SL62% welded wire mesh offers a cost-effective solution by reducing the amount of concrete required for reinforcement, thereby lowering overall project costs while maintaining quality and safety.

sl62 welded wire mesh factories

3. Versatility The versatility of SL62% welded wire mesh allows it to be adapted for various uses. It can be customized in terms of size, shape, and wire gauge to meet specific project requirements, making it a popular choice for both large-scale infrastructure projects and smaller applications.

4. Ease of Installation Welded wire mesh is relatively easy to handle and install compared to traditional rebar. This not only speeds up the construction process but also reduces labor costs, contributing to greater overall project efficiency.

The Role of Factories in Production

Factories that specialize in manufacturing SL62% welded wire mesh play a crucial role in ensuring the quality and consistency of this essential product. These factories are equipped with advanced machinery and technology that facilitate the high-volume production of welded wire mesh while adhering to safety and quality standards.

Quality control measures are integral to the manufacturing process, with rigorous testing conducted at various stages to ensure that the final product meets the required specifications. From raw material selection to final packaging, every step is meticulously monitored to maintain uniformity and reliability.

Moreover, these factories often offer customization services, allowing clients to specify particular dimensions and characteristics tailored to their unique needs. This adaptability positions welded wire mesh as a favored solution across a variety of sectors.

Conclusion

In conclusion, SL62% welded wire mesh factories are indispensable to the construction and manufacturing industries. The strength, cost-effectiveness, and versatility of SL62% welded wire mesh make it a highly sought-after material for various applications. As demand continues to grow, these factories will undoubtedly play a vital role in supporting infrastructure development and enhancing the resilience of projects worldwide. Investing in quality welded wire mesh from these specialized factories ensures that construction projects are built to last, providing safety and stability for years to come.

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.04,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Reliable

NewsAug.03,2025

-

Chain Link Fence: Durable, Versatile, and Reliable Fencing Solution|Galvanized Steel Fence Manufacturers

NewsAug.03,2025

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable, Versatile, Cost-Effective

NewsAug.03,2025

-

Heavy-Duty Welded Wire Mesh for Industrial Factories

NewsAug.03,2025

-

Galvanized Steel Fence-Anping Puersen|Durable,Flexible

NewsAug.02,2025