Dec . 18, 2024 14:40 Back to list

reinforcing mesh for industrial supplier

Reinforcing Mesh for Industrial Applications A Comprehensive Overview

In the realm of industrial construction and engineering, the importance of reinforcing mesh cannot be overstated. As an essential component in strengthening concrete structures, reinforcing mesh provides the much-needed support and resilience required for various applications. This article explores the features, benefits, and applications of reinforcing mesh for industrial suppliers, emphasizing its role in modern construction.

Understanding Reinforcing Mesh

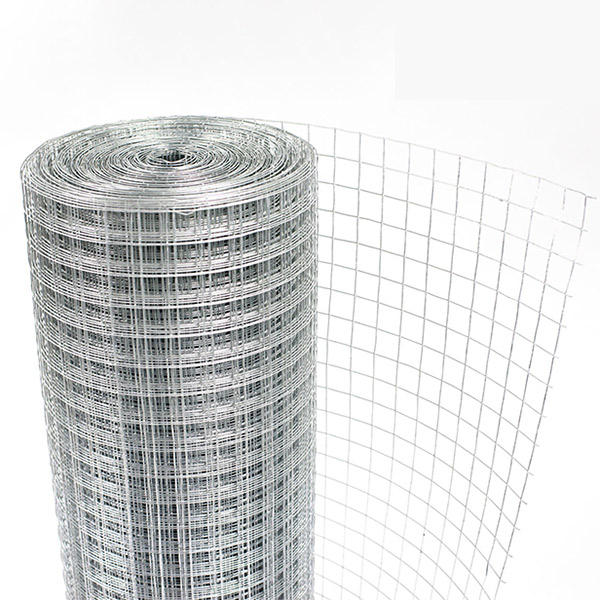

Reinforcing mesh, also known as reinforcing steel mesh or welded wire mesh, consists of a grid of steel wires that are welded together at their intersections to form a strong, stable matrix. This mesh is embedded within concrete slabs, walls, and foundations, enhancing their tensile strength and ductility. The primary purpose of reinforcing mesh is to control cracking and structural failure caused by the tension forces that concrete alone cannot withstand.

Key Features

1. Material Composition Reinforcing mesh is typically made from high-quality steel that meets specific industry standards. This ensures durability and longevity, making it suitable for demanding environments.

2. Variety of Designs Industrial suppliers offer different types of mesh, including square and rectangular grids, allowing for customization based on project requirements. The spacing and diameter of the wires can be adjusted to suit various applications.

3. Corrosion Resistance With advancements in technology, many manufacturers produce galvanized or epoxy-coated reinforcing mesh, providing enhanced resistance to corrosion. This is particularly important in environments exposed to moisture and chemicals.

4. Ease of Use Reinforcing mesh is lightweight and easy to handle, making it convenient for construction teams. It can be quickly installed, reducing labor costs and time on-site.

Benefits of Using Reinforcing Mesh

1. Enhanced Structural Integrity By integrating reinforcing mesh into concrete structures, engineers can significantly improve the tensile strength, helping to prevent cracks and failures under stress.

reinforcing mesh for industrial supplier

3. Sustainability Reinforcing mesh contributes to sustainable construction practices by extending the lifespan of structures. This reduces the need for frequent repairs and minimizes waste generated by demolition.

4. Versatility Reinforcing mesh is applicable across various industries, including construction, civil engineering, and infrastructure projects. It can be used in everything from residential buildings to heavy industrial applications.

Applications in Industry

Reinforcing mesh is used in a wide range of industrial applications

1. Commercial Construction From high-rise buildings to shopping malls, reinforcing mesh is essential for concrete floors, walls, and foundations.

2. Infrastructure Projects Roads, bridges, and tunnels benefit from the added strength and durability provided by reinforcing mesh.

3. Industrial Facilities Factories and warehouses often use reinforcing mesh in their flooring systems to accommodate heavy machinery and high traffic.

4. Agricultural Structures In the agricultural sector, reinforcing mesh is used in the construction of silos, barns, and storage facilities, ensuring they can withstand heavy loads and environmental stresses.

Conclusion

In conclusion, reinforcing mesh plays a critical role in the industrial supply chain by enhancing the strength and durability of concrete structures. Its unique features and benefits make it an essential component for various applications in construction and engineering. As industries continue to evolve and expand, the demand for high-quality reinforcing mesh will likely grow, highlighting the need for reliable suppliers who can deliver top-notch products. By investing in reinforcing mesh, companies can ensure the longevity and resilience of their structures while adhering to modern construction standards and sustainability practices.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025