Oct . 14, 2024 17:24 Back to list

Customized Galvanized Binding Wire for Secure and Durable Applications

Exploring OEM Galvanized Binding Wire A Comprehensive Overview

In the modern industrial landscape, the importance of reliable and durable materials cannot be overstated. One such material that has gained significant traction is the galvanized binding wire. Often employed in various applications, from construction to agricultural practices, this particular wire stands out due to its innovative design and robust properties. In this article, we will delve into the world of OEM galvanized binding wire, its manufacturing process, benefits, applications, and why it is a preferred choice for many industries.

What is Galvanized Binding Wire?

Galvanized binding wire is a type of wire coated with a layer of zinc through a process known as galvanization. This coating serves to protect the wire from corrosion and rust, enhancing its durability and lifespan. Typically made from high-quality low-carbon steel, galvanized binding wire exhibits excellent tensile strength, making it suitable for a wide range of binding and fastening tasks.

The Role of OEM in Manufacturing

Original Equipment Manufacturer (OEM) refers to companies that produce components or products that may be marketed by another manufacturer. In the context of galvanized binding wire, OEM manufacturers play a crucial role in customizing the product to meet specific client requirements. This means that clients can obtain wire that fits their exact specifications, including diameter, tensile strength, and length.

The OEM process often involves collaboration between manufacturers and clients to ensure that the final product meets quality standards while aligning with the aesthetic and functional requirements of the end-use. This flexibility and customization are significant advantages that OEM galvanized binding wire offers to various industries.

Benefits of Galvanized Binding Wire

1. Corrosion Resistance The primary benefit of galvanized binding wire is its resistance to rust and corrosion. The zinc coating acts as a sacrificial layer that protects the underlying steel from environmental factors, making it ideal for outdoor applications.

2. Durability Galvanized wire is designed to withstand harsh conditions, which makes it long-lasting. Industries that require robust materials for heavy-duty usage, like construction and agriculture, often rely on galvanized binding wire to ensure their projects remain intact over time.

3. Versatility Galvanized binding wire can be used in a multitude of applications. From securing plants in agricultural fields to bundling materials in construction sites, its versatility is one of its key features.

oem galvanized binding wire

5. Ease of Use The wire is easy to handle and can be cut and twisted to fit specific needs. This flexibility allows for innovative solutions in various binding tasks.

Applications of OEM Galvanized Binding Wire

Galvanized binding wire finds its application across numerous sectors

- Construction Used for tying rebar in concrete, supporting structures, and general site binding tasks, ensuring that building components remain securely joined.

- Agriculture Essential for fencing, trellises, and supporting plants, galvanized wire promotes healthy growth and protects crops.

- Manufacturing Utilized for bundling products and materials within factories, ensuring efficient handling during transport.

- Home Improvement Often used in DIY projects for crafting and repairs around the house, its availability in various sizes makes it accessible for homeowners.

Conclusion

In summary, OEM galvanized binding wire is more than just a simple material; it is a crucial component in various industries that require reliable and durable solutions for binding and fastening. Its corrosion resistance, durability, and versatility make it an excellent choice for a multitude of applications. As industries continue to evolve, the demand for high-quality, customized binding wire solutions will undoubtedly grow, making OEM manufacturers invaluable partners in meeting these needs. By investing in OEM galvanized binding wire, businesses can ensure they are equipped with the best materials to support their operational goals.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

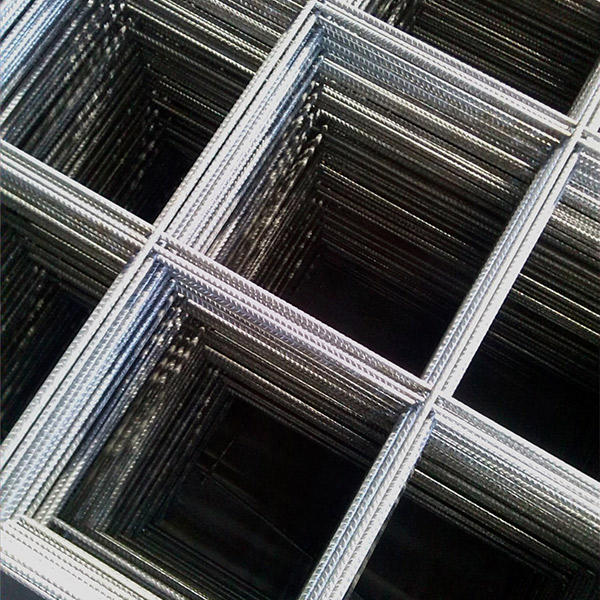

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025