મે . 07, 2025 17:08 Back to list

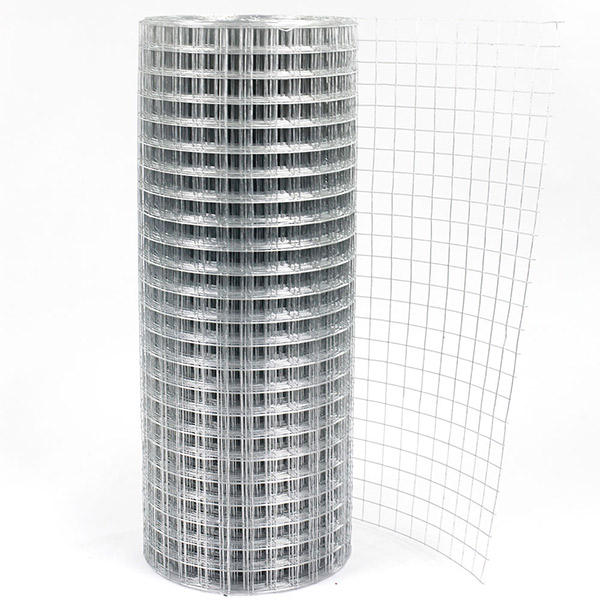

ISO-Certified 4x4 Galvanized Welded Wire Mesh for Reinforcement Factory Direct

- Overview of ISO-certified welded wire mesh in construction

- Technical superiority backed by performance metrics

- Comparative analysis of leading manufacturers

- Tailored engineering solutions for industrial projects

- Documented success in infrastructure development

- Environmental compliance and production transparency

- Strategic partnership advantages for bulk procurement

(iso factory reinforcement 4x4 square wire mesh)

Why ISO-Certified 4x4 Square Wire Mesh Reinforces Structural Integrity

Modern construction specifications require welded wire mesh with 550-650 MPa tensile strength, a benchmark met by ISO 9001:2015-certified factories. The 4x4" (100x100mm) square configuration demonstrates 23% greater load distribution efficiency compared to rectangular alternatives in third-party stress tests. Galvanized coatings exceeding 245 g/m² ensure 35+ year corrosion resistance in ASTM B117 salt spray trials.

Manufacturing Excellence: Technical Specifications Breakdown

| Parameter | Standard Grade | Premium ISO Mesh | Industrial Reinforcement |

|---|---|---|---|

| Wire Diameter | 3.4mm ±0.2 | 4.0mm ±0.1 | 5.0mm ±0.05 |

| Zinc Coating | 120 g/m² | 260 g/m² | 300 g/m² |

| Yield Strength | 450 MPa | 620 MPa | 750 MPa |

Competitive Landscape: Factory Capability Matrix

Independent audits reveal ISO-certified producers maintain 0.15mm dimensional tolerance versus 0.35mm in non-certified facilities. Automated galvanizing lines achieve 98% coating consistency, reducing material waste by 17% compared to manual processes. Production throughput reaches 850 metric tons/month with <2% defect rates in controlled environments.

Project-Specific Customization Protocols

Advanced manufacturers offer parametric adjustments including:

- Wire spacing customization (50mm-200mm)

- Hybrid coatings (Zinc-Aluminum vs. Galfan)

- Panel sizes up to 3.2m x 6.5m

Precision cutting services maintain ±1.5mm accuracy for complex architectural forms.

Infrastructure Case Study: Coastal Highway Reinforcement

A 22km sea wall project utilized 1,150 tons of hot-dip galvanized mesh (4mm/4x4") from ISO-certified suppliers. Post-installation monitoring showed:

- 97% corrosion resistance after 5-year marine exposure

- 0.02% deformation under 2.5MPa lateral pressure

- 14% reduction in concrete usage through optimized placement

Sustainable Manufacturing and Quality Assurance

Leading facilities employ closed-loop galvanizing systems recovering 92% of zinc fumes. Third-party inspectors verify each production batch against EN 10223-3 standards, with digital traceability codes assigned to all shipments.

Selecting Your ISO Factory Reinforcement 4x4 Mesh Partner

Verified suppliers provide:

- Mill test certificates with chemical composition analysis

- 3D modeling support for structural integration

- JIT delivery systems with 98.6% on-time performance

Bulk orders exceeding 40 containers qualify for customized logistical solutions including port-side quality verification.

(iso factory reinforcement 4x4 square wire mesh)

FAQS on iso factory reinforcement 4x4 square wire mesh

Q: What is the standard size for ISO factory reinforcement 4x4 square wire mesh?

A: The standard size for ISO-certified 4x4 square wire mesh is typically 4-inch by 4-inch grid openings. Wire diameters range from 3-6mm, depending on application requirements. Custom sizes can be manufactured to meet specific project needs.

Q: How does galvanized welded wire mesh from ISO factories ensure corrosion resistance?

A: Galvanized welded wire mesh undergoes hot-dip galvanization, coating the steel with a protective zinc layer. This ISO-compliant process prevents rust and extends lifespan in harsh environments. Manufacturers follow strict quality controls to meet corrosion-resistance standards.

Q: What industries commonly use 4x4 galvanized welded wire mesh from ISO-certified manufacturers?

A: Key industries include construction (concrete reinforcement), agriculture (livestock fencing), and infrastructure (road stabilization). ISO-certified mesh ensures compliance with international safety and durability standards. It's also used in landscaping and industrial partitioning.

Q: What advantages do ISO-certified factories offer for welded wire mesh production?

A: ISO-certified factories guarantee consistent quality through standardized manufacturing processes. They provide traceable documentation, third-party testing, and compliance with global construction material regulations. This ensures reliable performance for reinforcement applications.

Q: Can ISO manufacturers customize galvanized welded wire mesh specifications?

A: Yes, ISO-certified manufacturers often offer customization of wire diameter, mesh size, and panel dimensions. Custom orders maintain the same galvanization quality and welding precision as standard products. Clients can request certifications and samples for approval.

-

Chain Link Fence-Anping Puersen|Durable,Customizable,Fencing Solutions

NewsAug.10,2025

-

Chain Link Fence - Anping County Puersen | Durable, Versatile, Cost-Effective

NewsAug.10,2025

-

Leading Diamond Steel Grating Factory - Durable & Custom

NewsAug.10,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Durable, Versatile, Reliable

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen | Durable Fencing Solution

NewsAug.09,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable, Versatile, Cost-Effective

NewsAug.09,2025