ડીસેમ્બર . 14, 2024 00:08 Back to list

Suppliers of Galvanized Wire Mesh for Brick Masonry Applications and Construction Projects

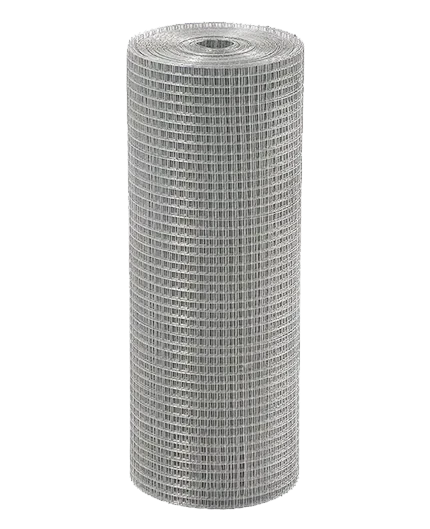

Exploring the Benefits of Galvanized Brick Coil Wire Mesh in Masonry A Guide for Suppliers

In the realm of construction and masonry, the importance of using durable materials cannot be overstated. Among the many options available, galvanized brick coil wire mesh has emerged as a preferred choice for builders and contractors worldwide. This article delves into the advantages of galvanized brick coil wire mesh and its implications for suppliers in the masonry industry.

Understanding Galvanized Brick Coil Wire Mesh

Galvanized wire mesh is made from steel that has been coated with a layer of zinc to enhance its resistance to corrosion. When formed into a coil, this type of wire mesh offers flexibility and ease of use in various construction applications. Within masonry, galvanized brick coil wire mesh is primarily used to reinforce structures, adding strength and longevity to brickwork while ensuring superior adherence between bricks and mortar.

Key Benefits for Builders and Contractors

1. Corrosion Resistance

One of the most significant advantages of galvanized wire mesh is its resistance to rust and corrosion. This protection means that the mesh can endure harsh environmental conditions, making it ideal for both indoor and outdoor applications. For builders located in areas with high humidity or frequent rain, galvanized wire mesh is a reliable choice that can withstand moisture without succumbing to degradation.

2. Enhanced Structural Integrity

Masonry structures benefit from added reinforcement, which is precisely what galvanized wire mesh provides. By integrating this mesh into brickwork, contractors can significantly improve the overall strength of the structure. This reinforcement is especially critical in areas prone to seismic activity, where additional support can prevent structural failure during earthquakes.

3. Cost-Effectiveness

Over the lifecycle of a building, choosing galvanized brick coil wire mesh can lead to considerable cost savings. The durability of galvanized materials reduces the need for frequent repairs and replacements, translating to lower maintenance costs. Furthermore, its ease of installation can also result in reduced labor costs for contractors, making it a financially savvy choice.

4. Versatility in Applications

galvanized brick coil wire mesh masonry suppliers

Galvanized wire mesh can be employed in various masonry applications—from reinforcement in walls to support in arches and other load-bearing structures. This versatility means that suppliers can cater to a broad range of projects, including residential homes, commercial buildings, and industrial facilities. By offering different gauges and mesh sizes, suppliers can meet the specific needs of different construction projects.

Implications for Suppliers in the Masonry Industry

As demand for robust and reliable masonry materials continues to grow, suppliers of galvanized brick coil wire mesh have a unique opportunity to position themselves effectively in the market. Here are some strategies suppliers can leverage to maximize their market presence

1. Education and Awareness

Suppliers should focus on educating contractors and builders about the advantages of using galvanized wire mesh in their masonry projects. Providing informational materials, hosting workshops, and engaging in networking events can help raise awareness of the benefits and applications of this product.

2. Diverse Inventory

Maintaining a diverse inventory of galvanized brick coil wire mesh—varying in gauge, size, and specifications—ensures that suppliers can meet the diverse needs of contractors and builders. Being able to offer customized solutions can also enhance supplier-client relationships.

3. Quality Assurance

Emphasizing the high quality of galvanized products is crucial for suppliers. Ensuring that the mesh meets industry standards for strength and durability can instill confidence in customers and set suppliers apart from competitors.

Conclusion

Galvanized brick coil wire mesh is an invaluable resource in the masonry industry, providing numerous benefits such as corrosion resistance, structural integrity, cost-effectiveness, and versatility. For suppliers, understanding the advantages of this product and implementing effective strategies can help capture the growing demand from builders and contractors. As construction methods advance and materials evolve, the role of galvanized brick coil wire mesh in creating enduring structures is sure to remain pivotal.

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025