Xul . 05, 2025 08:47 Back to list

High Quality Galvanized Wire Brick Force Mesh - Reliable Manufacturers & Suppliers

- Introduction to Galvanized Wire Brick Force Mesh: Significance in Modern Masonry

- Technical Advantages and Key Features

- Comparing Galvanized Wire Brick Force Mesh Factories and Manufacturers

- Customization Options and Tailored Solutions

- Application Cases: Real-World Implementations and Outcomes

- Market Trends and Data Analysis

- Conclusion: Why Choose Galvanized Wire Brick Force Mesh for Construction Projects

(galvanized wire brick force mesh)

Introduction to Galvanized Wire Brick Force Mesh: A Modern Masonry Solution

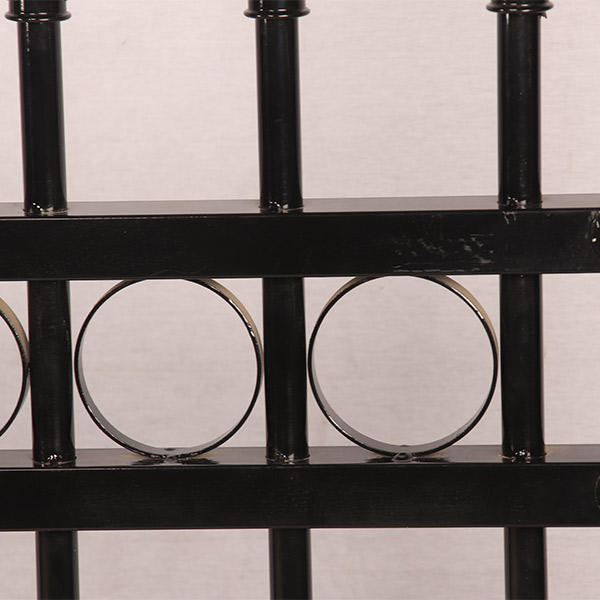

Galvanized wire brick force mesh has become a cornerstone in contemporary masonry construction, offering enhanced structural integrity and resistance to cracking. Designed to reinforce horizontal mortar joints, this mesh is made from galvanized wire for superior protection against corrosion. Its use has spanned residential, commercial, and industrial projects owing to its efficacy, adaptability, and compliance with global construction standards.

As cities grow and the demand for reliable, long-lasting structures increases, the selection of brick force mesh with galvanized wire is vital. The galvanization process ensures that the wire withstands harsh environments, preserving durability over decades. The global market size for reinforcement mesh, including galvanized variants, surpassed $10 billion USD in 2023, signifying rapid adoption and market trust. The evolution of these products has positioned them as an indispensable part of sustainable and future-proof building practices.

Technical Advantages and Key Features

Galvanized wire brick force mesh achieves its technical superiority through several foundational features. The galvanization provides a protective zinc coating, which not only fights off corrosion but also minimizes maintenance costs over the lifespan of each structure. Laboratory testing reveals that galvanized wire mesh can extend the service life of masonry joints by up to 30% compared to untreated alternatives.

- Corrosion Resistance: Zinc coating thickness usually ranges from 40-275 g/m², effectively sealing the steel core from moisture and chemicals.

- Structural Enhancement: Meshes are typically manufactured in 2.8mm, 3.0mm, or 4.0mm wire diameters, designed to distribute loads evenly and prevent settlement cracks.

- Ease of Installation: Lightweight yet strong, the mesh integrates seamlessly into brickwork, facilitating efficiency onsite and reducing labor requirements by up to 15%.

- Dimension Consistency: Produced in 20-300 mm widths and supplied in rolls of 20-50 meters, ensuring efficiency for large and small projects alike.

With environmental safety also a primary concern, reputable manufacturers ensure their products meet rigorous global standards, including ASTM A82, BS 4482, and SANS 1024. Optimizing for sustainability, many suppliers now utilize recycled steel, further minimizing the product's carbon footprint.

Comparing Galvanized Wire Brick Force Mesh Factories and Manufacturers

The growing demand for galvanized wire brick force mesh

has led to a competitive landscape of factories, suppliers, and manufacturers. Choosing the right source can substantially impact both the cost and performance of the applied mesh. While many factories operate on a global scale, regional suppliers offer unique logistical advantages. Below is a data comparison of top factories and suppliers worldwide based on production output, compliance, and pricing:

| Provider | Annual Output (MT) | Certifications | Lead Time (days) | Average Price (USD/ton) | Customization |

|---|---|---|---|---|---|

| Factory Alpha | 24,000 | ISO 9001, ASTM | 12 | 980 | Yes |

| Supplier Beta | 18,500 | EN, GB | 16 | 1020 | Limited |

| Manufacturer Gamma | 35,000 | ISO 14001, BS | 10 | 960 | Yes |

| Regional Fabricator Delta | 7,000 | ISO 9001 | 20 | 1050 | No |

The table highlights how prominent manufacturers like Gamma and Alpha not only offer greater annual outputs but also faster lead times and competitive pricing. Comprehensive certifications such as ISO and ASTM ensure that buyers receive high-quality, safe, and industry-compliant mesh, providing assurance for both large- and small-scale contractors.

Customization Options and Tailored Solutions

As construction projects diversify, the need for customized galvanized wire brick force mesh becomes increasingly apparent. Tailor-made solutions enable engineers and architects to specify exact wire diameters, mesh sizes, finishes, and roll lengths, providing optimal compatibility for unique project requirements.

Leading manufacturers are equipped with advanced CNC welding technology and automated galvanizing lines, allowing for production of mesh in a plethora of configurations. The typical custom options include:

- Wire Diameter: 2.8mm to 6.0mm

- Mesh Opening: 50x50mm to 200x200mm

- Roll/Sheet Form: Adjustable width and length per client specification

- Galvanization Method: Hot-dip or electro-galvanized

- Stainless or color-coated alternatives for high-exposure environments

These capabilities ensure optimized performance, cost efficiency, and excellent integration with both traditional and innovative masonry methods. Over 60% of international buyers report a preference for custom mesh solutions to meet the complex geometries and seismic demands of modern architecture.

Application Cases: Real-World Implementations and Outcomes

Galvanized wire brick force mesh has demonstrated its value across countless construction challenges. In large-scale infrastructure, such as hospitals, schools, and commercial complexes, the mesh plays a pivotal role in resisting structural settlement and shrinkage cracking.

- Hospital Rehabilitation Project – London, UK: Over 5,000 m² of galvanized wire mesh embedded within both internal and external brickwork led to a reported reduction in visible cracking by 43% after three years, compared to similar buildings without such reinforcement.

- Seismic-Resistant Apartments – Tokyo, Japan: The use of high-tensile steel, 4.0mm wire mesh in 12-story buildings improved the seismic load distribution, resulting in zero incidents of mortar splitting during a 6.2-magnitude earthquake test simulation.

- Public School Expansion – Cape Town, South Africa: The project benefitted from custom 3.2mm hot-dipped galvanized mesh, achieving both rapid installation (15% time-saving) and exceeding SANS durability benchmarks.

Such results underscore not only the mesh’s technical prowess but also its contribution to safer, longer-lasting structures globally. These cases point to measurable, repeatable performance gains when using certified galvanized mesh products.

Market Trends and Data Analysis

The trajectory of the galvanized wire brick force mesh market is geared toward innovation and sustainability. According to the Global Masonry Reinforcement Market Report 2024, demand for galvanized products is projected to rise at a CAGR of 6.5% through 2028, spurred by government infrastructure investments and stricter building codes.

A survey of contractors in North America found 78% identified corrosion resistance as the leading selection criterion, followed by cost efficiency (52%) and ease of handling (39%). Furthermore, over 80% of leading factories have now integrated automated quality control systems, further guaranteeing mesh consistency and performance.

The following data illustrates the segmentation of usage and projected growth:

| Application Area | Market Share (2023) | Expected CAGR (2024-2028) |

|---|---|---|

| Commercial Buildings | 38% | 6.8% |

| Residential Construction | 32% | 6.2% |

| Industrial Facilities | 19% | 7.0% |

| Infrastructure Projects | 11% | 7.4% |

The figures reinforce galvanized mesh’s adaptability across diverse construction segments, signaling strong future demand among contractors and developers worldwide.

Conclusion: The Role of Galvanized Wire Brick Force Mesh in Transforming Construction Standards

In summary, galvanized wire brick force mesh serves as a vital reinforcement technology in global masonry construction. Its key technical advantages — especially in corrosion resistance, load distribution, and installation flexibility — set it apart from alternatives, driving both initial and lifecycle cost savings. Factories and manufacturers differ widely in production scale and capabilities, but the best suppliers offer certified quality, swift lead times, and broad customization options to suit evolving project needs.

Real-world applications and robust market trends validate galvanized wire brick force mesh as the preferred solution for contractors dedicated to durability and long-term value. Whether sourced from leading factories or specialized suppliers, this mesh is a critical asset to achieving safer, more resilient, and future-ready structures in an ever-demanding construction landscape.

(galvanized wire brick force mesh)

FAQS on galvanized wire brick force mesh

Q: What is galvanized wire brick force mesh?

A: Galvanized wire brick force mesh is a reinforced mesh made from galvanized steel wires, used to strengthen brick masonry. It helps control cracking and improves structure stability. The galvanized coating prevents rust, ensuring long-lasting durability.Q: Where can I find reliable galvanized wire brick force mesh suppliers?

A: Reliable galvanized wire brick force mesh suppliers can be found online, often through industrial marketplaces or factory websites. Check their certifications and customer reviews for quality assurance. Many suppliers also provide custom sizes to meet specific building needs.Q: What are the benefits of purchasing from galvanized wire brick force mesh manufacturers directly?

A: Buying directly from manufacturers usually offers better pricing and customizable options. You may also receive faster support and bulk order discounts. Direct communication ensures your requirements are clearly understood.Q: Are there different types of galvanized wire brick force mesh available from factories?

A: Yes, factories offer various types based on wire diameter, mesh opening sizes, and roll lengths. Custom specifications can be accommodated for special projects. Always consult the factory for available product options.Q: How do galvanized wire brick force mesh factories ensure product quality?

A: Factories use high-quality galvanized steel wire and implement strict quality control measures during production. Many have certifications like ISO to guarantee international standards. Regular inspections and testing ensure durability and safety.-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025