Set . 05, 2024 20:12 Back to list

High-Quality Cold Drawn Wire Gauge 6mm to 12mm | Durable & Precision Engineered

The Importance of 6mm-12mm Cold Drawn Wire in Manufacturing

In the landscape of modern manufacturing, the significance of high-quality materials cannot be overstated. Among various forms of industrial materials, 6mm-12mm wire gauge cold drawn wire stands out due to its remarkable strength and versatility. This type of wire is produced through a meticulous process known as cold drawing, which enhances the material's properties, making it an essential choice for diverse applications.

Cold drawn wire is made by pulling a metal rod through a series of dies, thereby reducing its diameter and increasing its length without the addition of heat. This process not only diminishes the wire's diameter but also refines its microstructure, resulting in improved tensile strength, greater ductility, and enhanced surface finish. For wires ranging from 6mm to 12mm in diameter, the cold drawing process is particularly effective in achieving optimal characteristics that are critical for various industrial applications.

One of the primary uses of cold drawn wire in this gauge range is in the fabrication of components for the automotive industry. Cold drawn wires serve as essential raw materials for making parts such as springs, fasteners, and structural components. Their enhanced tensile strength is crucial for withstanding the rigorous demands placed on automotive parts, ensuring reliability and longevity.

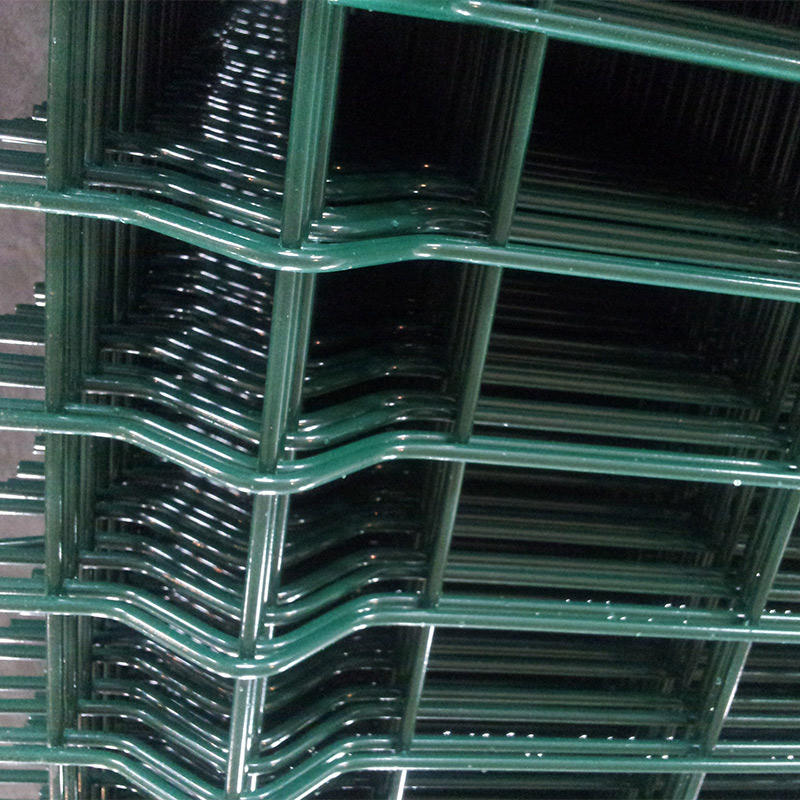

6mm-12mm wire gauge cold drawn wire factory

Additionally, these wires are widely used in construction and infrastructure development. The construction industry benefits from utilizing cold drawn wire for reinforcement in concrete structures. The wire’s superior mechanical properties contribute significantly to the strength and durability of buildings, bridges, and other infrastructures. With the increasing focus on safety and longevity in construction, the demand for such quality materials continues to rise.

Another key application for cold drawn wire in the 6mm-12mm range is in the manufacturing of wire ropes and cables. These products require wires that can support substantial loads while maintaining flexibility. The cold drawing process provides the necessary toughness and resilience, making the wires suitable for applications in cranes, elevators, and various heavy lifting operations.

Moreover, the precision offered by cold drawn wire cannot be overlooked. Manufacturers benefit from the consistent diameter and superior surface finish that cold drawn processes deliver. This uniformity is vital for products that require precise measurements and fit, enhancing the overall quality and performance of the end products.

In conclusion, the role of 6mm-12mm wire gauge cold drawn wire in manufacturing is undeniably significant. Its strength, versatility, and precision make it a favored choice in various industries, including automotive, construction, and lifting applications. As industries continue to evolve and demand higher standards for materials, the importance of cold drawn wire will only grow, solidifying its place as a cornerstone in contemporary manufacturing practices.

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025