Dec . 11, 2024 09:58 Back to list

China Twisted Bars for Grating Welding Applications and Innovations in Construction

Twisted Bars for Grating Welding An Overview of China’s Manufacturing Edge

In the construction and infrastructure sectors, the importance of high-quality materials cannot be overstated. Among various options, twisted bars have emerged as an essential component, particularly in applications involving grating welding. This article explores China’s position as a leading manufacturer of twisted bars for grating welding, examining the production processes, benefits, and implications for the global market.

Understanding Twisted Bars

Twisted bars, often used in concrete reinforcement, feature a unique design that enhances their mechanical properties. The twisting pattern increases the bar's tensile strength, making it more resilient against the stresses of various applications. In the context of grating welding, twisted bars are specifically utilized to create robust and durable steel grating systems, which serve critical roles in industrial flooring, platforms, drainage covers, and more.

China’s Manufacturing Capabilities

China has positioned itself as a dominant player in the global steel market, particularly in the production of twisted bars. With an extensive network of factories and access to abundant raw materials, Chinese manufacturers are capable of producing large quantities of twisted bars efficiently and cost-effectively. The country’s advancements in technology plays a significant role in optimizing production processes. Automated machinery and innovative techniques allow manufacturers to maintain high standards of quality while also meeting the growing demand.

The establishment of rigorous quality control measures further enhances the appeal of Chinese twisted bars. Manufacturers adhere to international standards, ensuring that their products can compete in the global market. This commitment to quality and efficiency has helped China become a key supplier for numerous construction and infrastructure projects worldwide.

Benefits of Using Twisted Bars for Grating Welding

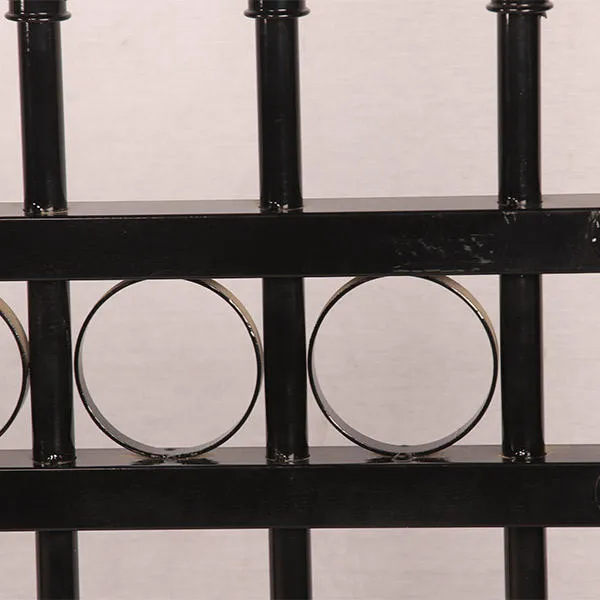

china twisted bars for grating welding

Using twisted bars for grating welding offers numerous advantages, making them a preferred choice among engineers and architects. One of the primary benefits is their superior strength-to-weight ratio. The twisting pattern provides enhanced structural integrity, allowing for thinner and lighter designs without compromising on durability. This means that grating systems can be installed more easily and are often more cost-effective due to reduced material usage.

Moreover, twisted bars provide excellent resistance to fatigue. In environments where the grates are subjected to heavy loads and dynamic forces, such as in industrial settings, the durability of twisted bars helps prevent failures that could lead to costly downtimes and safety issues.

Another significant advantage is the improved welding characteristics of twisted bars. The twisted configuration facilitates better penetration of the weld, leading to strong bonds and a longer service life of the grating systems. This is particularly important in applications where structural integrity is paramount.

Global Implications

As China continues to excel in the manufacturing of twisted bars for grating welding, the global market is witnessing a shift in supplier dynamics. The combination of affordability, quality, and innovation has made Chinese twisted bars not only a favorable choice for local construction projects but also an attractive option for international buyers. Emerging economies, in particular, stand to benefit from China’s competitive edge, as they ramp up infrastructure projects to support their growth.

However, the increasing reliance on Chinese manufacturers also raises concerns surrounding the sustainability of production practices and environmental impact. As such, there is a growing demand for transparent sourcing and responsible manufacturing within the industry. Companies worldwide are encouraged to collaborate with manufacturers who prioritize sustainability and ethical practices.

Conclusion

China’s twist on manufacturing twisted bars for grating welding exemplifies the country’s industrial prowess. With advanced technology, a commitment to quality, and an understanding of global market demands, China has solidified its role as a vital supplier in the construction industry. As the market evolves, it remains essential for manufacturers and consumers alike to prioritize sustainability and innovation to ensure the continued growth and success of the industry.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025