Dec . 16, 2024 09:09 Back to list

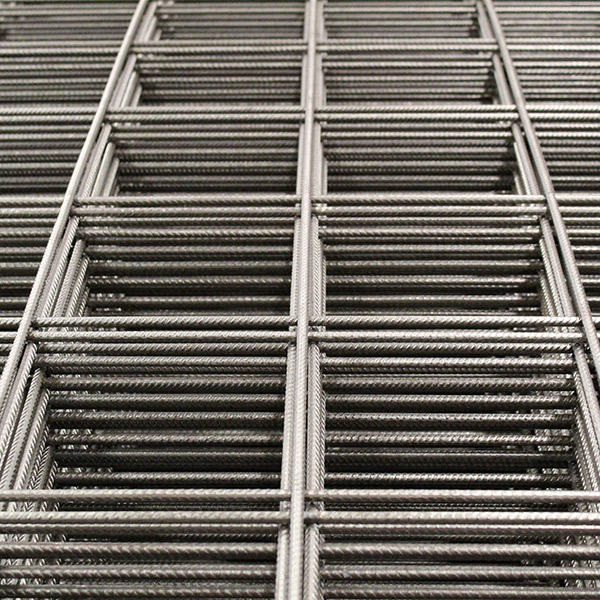

Welded Wire Mesh Suppliers for Concrete Slabs and Construction Applications

The Role of Welded Wire Mesh in Concrete Slabs An Overview for Manufacturers

In the construction industry, the integrity and durability of concrete structures are of paramount importance. One essential component that significantly enhances the performance of concrete slabs is welded wire mesh (WWM). As a manufacturer in this sector, understanding the benefits, applications, and production processes of welded wire mesh can position your business for success in a competitive market.

What is Welded Wire Mesh?

Welded wire mesh is a grid-like structure made from intersecting wires that are welded together at their intersections, forming a robust reinforcement framework. Typically available in various sizes and grades, WWM can be fabricated from carbon or stainless steel, offering versatility in application and durability. Its primary function is to provide additional tensile strength to concrete, thereby preventing cracking and improving overall structural performance.

Benefits of Using Welded Wire Mesh in Concrete Slabs

1. Enhanced Structural Integrity When incorporated into concrete slabs, welded wire mesh distributes loads more evenly, which helps to prevent cracking under pressure. This is particularly important in large slabs like pavements, industrial floors, and bridge decks, where heavy loads and dynamic movements are common.

2. Easy Installation Welded wire mesh is relatively easy to transport and install compared to traditional rebar reinforcement. The mesh comes in sheets or rolls, allowing for quick placement, which enhances productivity on job sites and reduces labor costs.

3. Cost-Effective Solution The durability and strength imparted by welded wire mesh can lead to cost savings over time. By reducing the need for repairs caused by cracking and extending the lifespan of concrete structures, WWM proves to be a worthwhile investment.

4. Versatility in Applications Welded wire mesh is suitable for a variety of concrete applications, including residential and commercial flooring, precast concrete elements, and even retaining walls. Its adaptability makes it a valuable resource for manufacturers seeking to diversify their product offerings.

5. Improved Resistance to Shrinkage Cracking Concrete slabs are susceptible to shrinkage as they cure, which can lead to cracks. The use of WWM minimizes this risk by providing a mechanical connection throughout the slab, reducing the likelihood of isolated cracks forming.

welded wire mesh in concrete slab manufacturers

Manufacturing Welded Wire Mesh

For manufacturers, the production of welded wire mesh involves several critical steps

1. Wire Selection The first step is choosing the appropriate wire material based on the intended application. Low-carbon steel is the most common choice, though stainless steel may be preferred for corrosive environments.

2. Drawing and Cutting The selected wire is drawn to the desired thickness and then cut to specified lengths. This ensures that the mesh can accommodate various slab sizes and designs.

3. Welding Process The wires are arranged in a grid pattern and electrically welded at the intersection points. This step is crucial, as the quality of the welds significantly influences the mesh's strength and performance.

4. Finishing Treatments After welding, the mesh may undergo additional treatments such as galvanization or epoxy coating to enhance its corrosion resistance and extend its service life.

5. Quality Control Rigorous testing is essential to ensure that the welded wire mesh meets industry standards. This includes checking the tensile strength, weld integrity, and dimensional accuracy.

Conclusion

As a manufacturer, staying informed about the advantages and production of welded wire mesh can enhance your offerings in the concrete construction market. By providing high-quality WWM, you not only fulfill a critical need in the industry but also contribute to the safety and longevity of concrete structures. Emphasizing the benefits of welded wire mesh in your marketing strategies can help attract customers looking for reliable reinforcement solutions. In an ever-evolving construction landscape, your commitment to quality and innovation in welded wire mesh will undoubtedly set you apart from the competition.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025