Dec . 07, 2024 02:49 Back to list

Production of Deformed Steel Bars Using Iron Rods in Manufacturing Facilities

The Production of Deformed Steel Bars in Iron Rod Factories

Deformed steel bars, commonly known as rebar, are a crucial material in construction, providing structural integrity and support to various concrete structures. Iron rod factories play a significant role in producing these essential components, which are used extensively in building bridges, highways, and large buildings. The process of manufacturing deformed steel bars involves several stages, from the melting of raw materials to the final processing and quality assurance. This article will explore the intricacies of this production process and its importance in the construction industry.

The Production of Deformed Steel Bars in Iron Rod Factories

After refining, the molten steel is cast into large billets. These billets are allowed to cool and solidify before undergoing further processing. The next stage in the production of deformed steel bars is hot rolling. In this process, the billets are heated and passed through a series of rollers to reshape them into long, thin rods. It is during this phase that the characteristic deformations, or ribs, are introduced to the steel bars. These ribs enhance the bond between the steel and the concrete, significantly improving the overall strength and durability of the constructed elements.

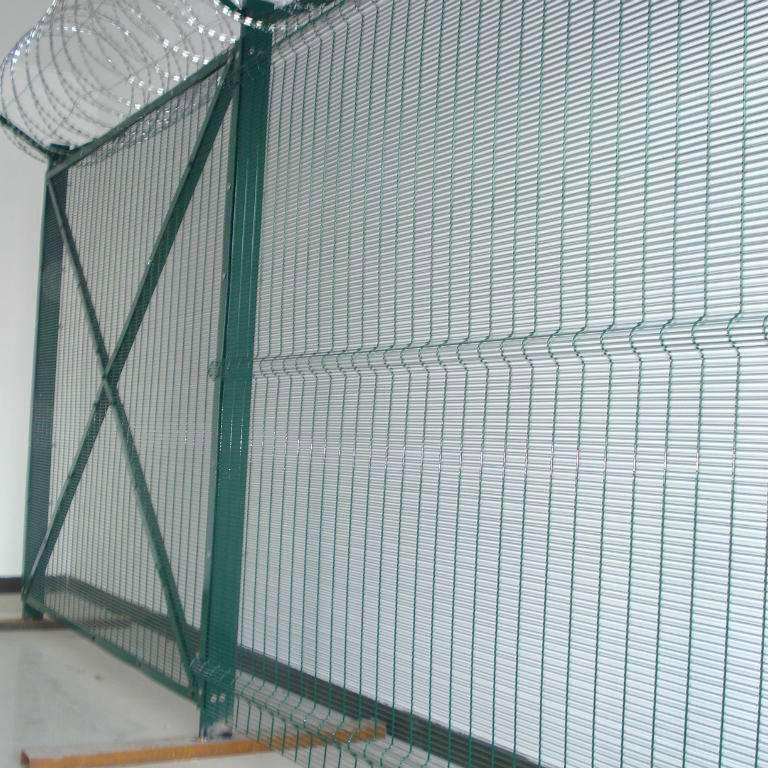

iron rods deformed steel bar factory

Once the rolling process is completed, the hot-rolled deformed bars are cut into specific lengths according to customer requirements. However, before they are dispatched to construction sites, the bars undergo a rigorous quality control process. This includes metallurgical testing to ensure that the steel meet industry standards for strength, ductility, and corrosion resistance. Factors like chemical composition, mechanical properties, and surface quality are evaluated to guarantee that the products are fit for their intended purpose.

In addition to maintaining high production standards, iron rod factories are increasingly adopting advanced technologies to enhance efficiency and reduce environmental impact. Automation and digitization are becoming prevalent, allowing for real-time monitoring of the manufacturing process. This not only improves precision but also helps in tracking resource usage, which is vital in minimizing waste and emissions.

The market demand for deformed steel bars is influenced by several factors, including construction activity, infrastructure development, and economic growth. In regions experiencing rapid urbanization, there is a heightened demand for robust and reliable construction materials. As such, iron rod factories are constantly innovating and improving their production methodologies to keep pace with the evolving needs of the industry.

In conclusion, the production of deformed steel bars in iron rod factories is a complex process that involves the transformation of raw materials into a critical construction component. From melting and casting to rolling and quality assurance, each step in the manufacturing process is crucial for ensuring the durability and reliability of the final product. With continued advancements in technology and a focus on sustainability, iron rod factories are well-positioned to meet the growing demands of the construction industry, contributing to safer and more resilient infrastructure worldwide. As urban growth continues to skyrocket, the role of deformed steel bars in supporting and shaping our built environment cannot be overstated.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025